Stereoscopic green cultivation system

A three-dimensional, green technology, applied in cultivation, soilless cultivation, agricultural gas emission reduction, etc., can solve problems such as reducing cultivation efficiency, and achieve the effects of improving production efficiency, fast installation and disassembly, and convenient production management.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

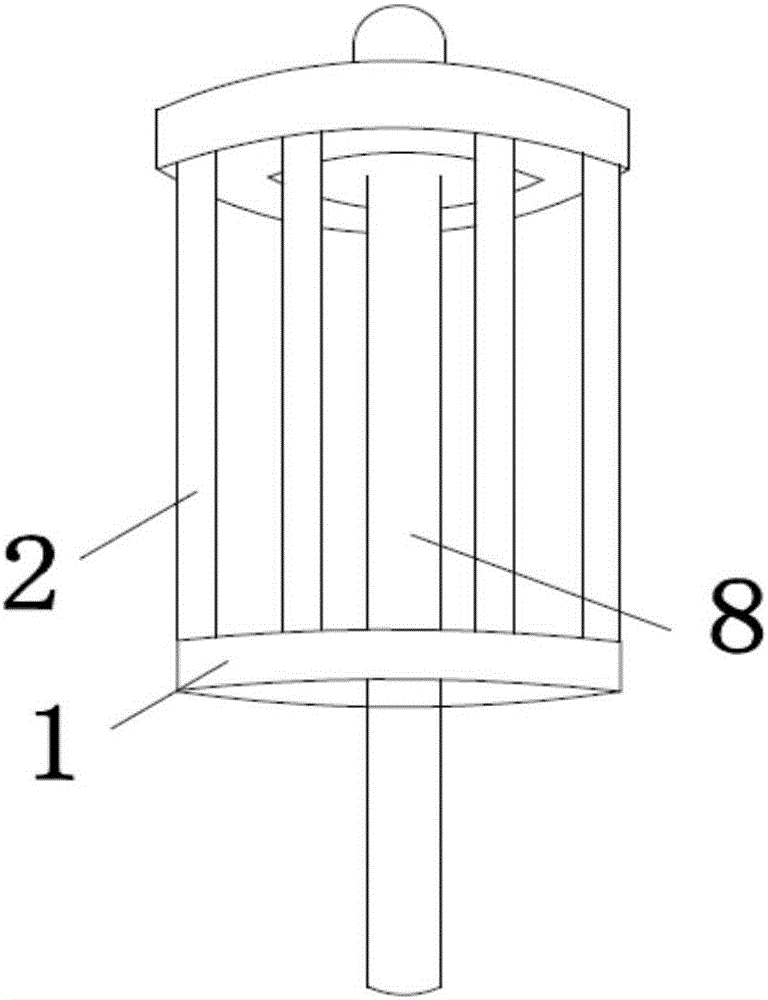

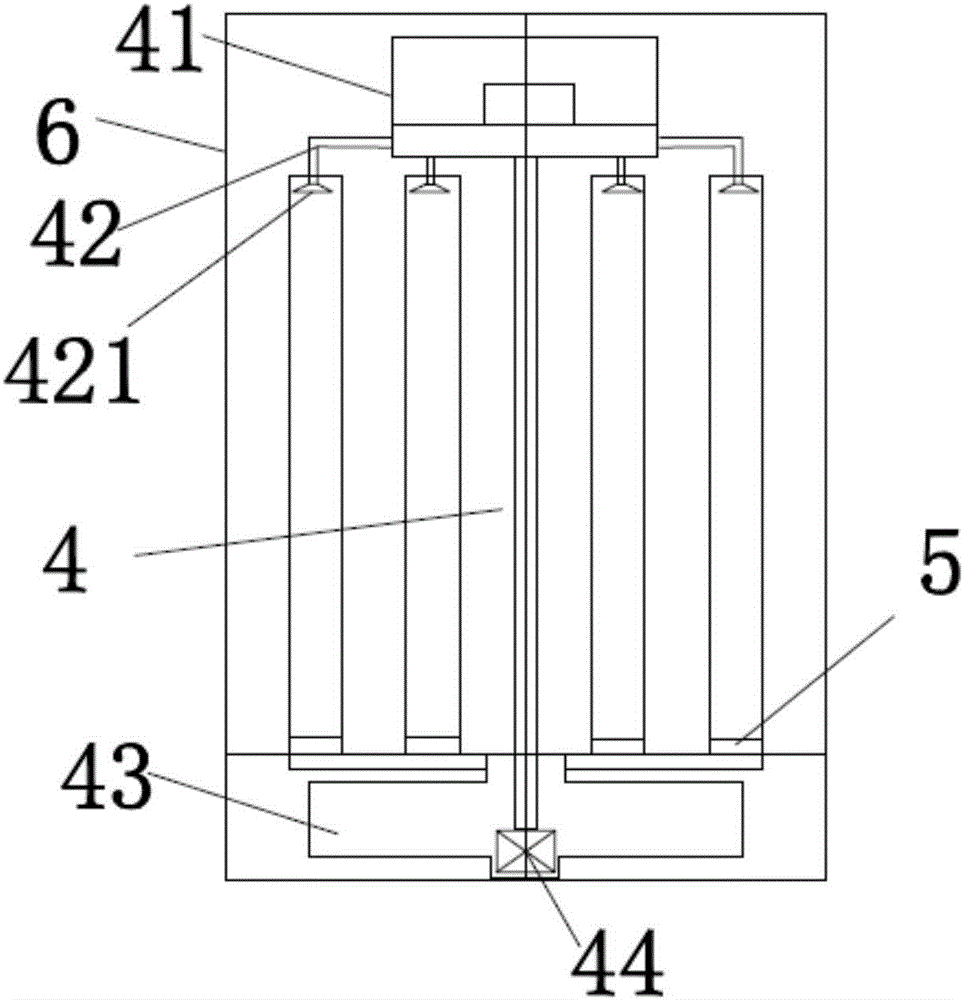

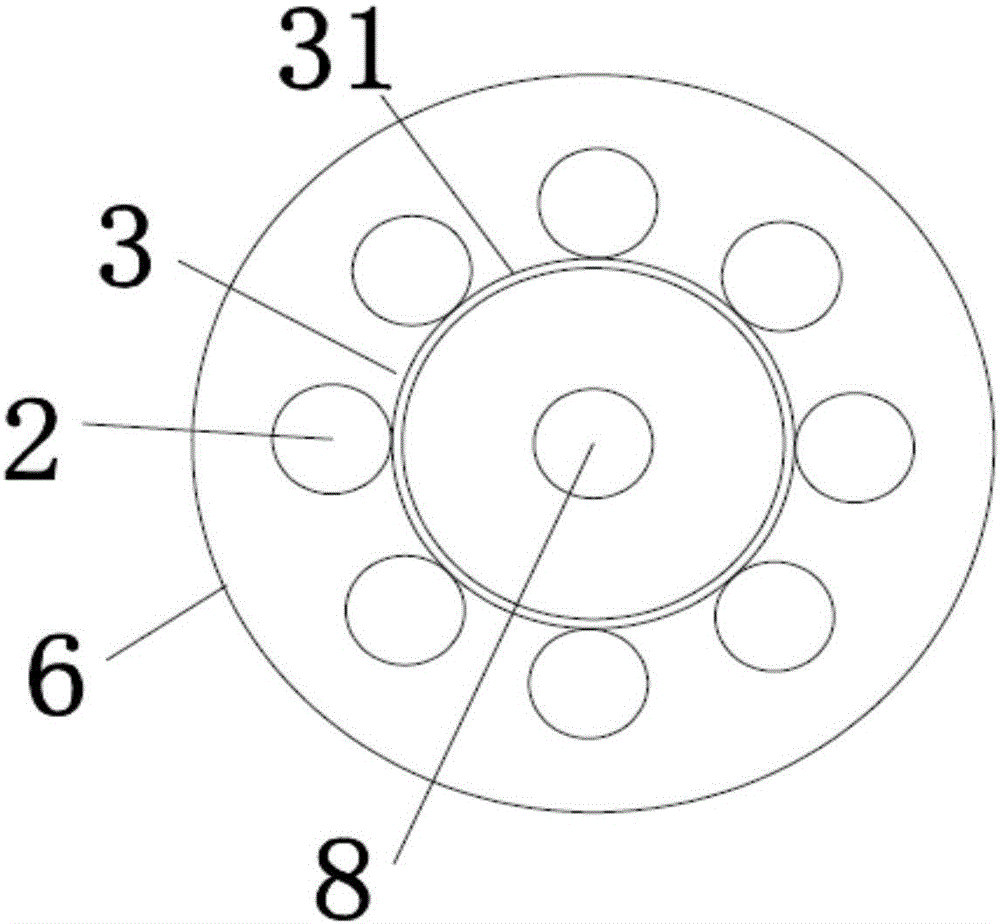

[0029] combined with Figure 1-4 As shown, the present embodiment provides a three-dimensional green cultivation system, including a support base 1 at the bottom, a plurality of cultivation columns 2 , a driving device 3 , a water circulation system 4 , a water filtering device 5 and a protective cover 6 . like Figure 4 As shown, in the present embodiment, the cultivation column 2 is an upper and lower opening structure, and the support seat 1 can be a round platform, and the cultivation column 2 is installed on the support seat 1 and can rotate along the axial direction of the cultivation column 2. The specific structure can be The upper surface of the support seat 1 has a plurality of installation grooves, the cultivation column 2 is installed in the installation groove, and the liquid flowing out from the lower opening of the cultivation column 2 can flow into the water circulation system. The cultivation columns 2 are evenly distributed along the circumference of the sup...

Embodiment 2

[0041] On the basis of the above-mentioned embodiments, this embodiment improves the above-mentioned control device. The control device of this embodiment has a waterproof shell. Since the cultivation system is in a relatively high temperature environment, it is necessary to cool the inside of the control device to ensure its service life, thereby improving the service life and working efficiency of the entire cultivation system.

[0042] The control device of this embodiment includes a housing and a PCB board. Electronic components are installed on the first surface of the PCB board, and a cooling pipeline is arranged above the second surface. The cooling pipeline communicates with the cooling gas generating device, and the electric valve is set On the cooling pipeline, the opening of the electric valve faces the electronic components so that the sprayed cooling airflow faces the electronic components; the opening of the electric valve is also provided with a valve plate perpe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com