A funnel-type crystallizer copper plate mold for continuous casting of thin slabs

A mold copper plate and funnel-type technology is applied in the production and use of continuous casting thin slab copper plate molds, which can solve the problems of continuous casting billet copper plate molds being prone to cracks, affecting service life, etc. Thermal conductivity, the effect of increasing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

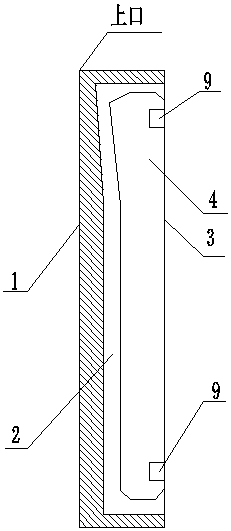

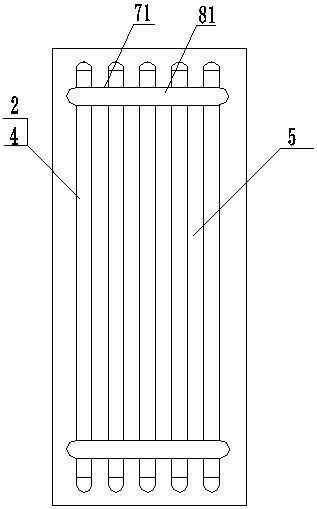

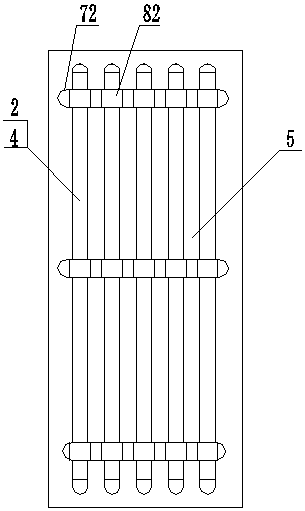

[0019] Example one: such as figure 1 , figure 2 , Image 6 As shown, a continuous casting thin slab funnel mold copper plate mold includes a funnel-shaped working surface 1 on the front, a cooling water tank 2 with cooling function and a cooling water tank surface 3 on the back, and an inserted cooling water tank 2 to control the cooling water tank 2 The cross-sectional size of the insert 4 also includes the ribs 5 between the cooling water tanks 2 and the water holes 6 on the ribs 5. The copper plate mold is called the upper part near the mouth of the funnel, and the opposite is called the lower part. The strip 4 is connected with two positioning mechanisms arranged on the upper and lower parts of the cooling water tank surface 3, and the cross-sectional area formed by the insert 4 and the cooling water tank 2 is fixed by the positioning mechanism.

[0020] The positioning mechanism is composed of a long keyway 71, a long key 81, and a slot 9 at the connection part of the inser...

Embodiment 2

[0022] The second embodiment: the difference from the first embodiment is that: optimally, starting from the upper mouth of the copper plate mold and reaching the distance of 250mm from the upper mouth, the depth dimension of the corresponding part of the cooling water tank and the corresponding cross-section of each part of the insert The difference in depth dimension gradually increases by 15%, from the distance 250mm from the upper mouth to the lower mouth of the copper plate mold, the difference between the depth dimension of each part of each insert and the depth dimension of the corresponding part of the corresponding cooling water tank remains unchanged.

Embodiment 3

[0023] The third embodiment: the difference from the first embodiment is that: preferably, starting from the upper mouth of the copper plate mold, until the distance from the upper mouth is 300mm, the depth dimension of the corresponding part of the cooling water tank and the corresponding cross section of each part of the insert The difference in depth dimension gradually increases by 10%. From the distance of 300mm from the upper mouth to the lower mouth of the copper plate mold, the difference between the depth dimension of the cross section of each part of each insert and the depth dimension of the corresponding part of the corresponding cooling water tank remains unchanged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com