Intelligent saw blade special for Korean pine plate

A saw blade and wood board technology, applied in the field of saw blades, can solve the problems of easy damage to the tool life, low processing efficiency, saw blade or material deformation, etc., to improve the flatness of the incision, reduce the generation of dust, reduce vibration and noise. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

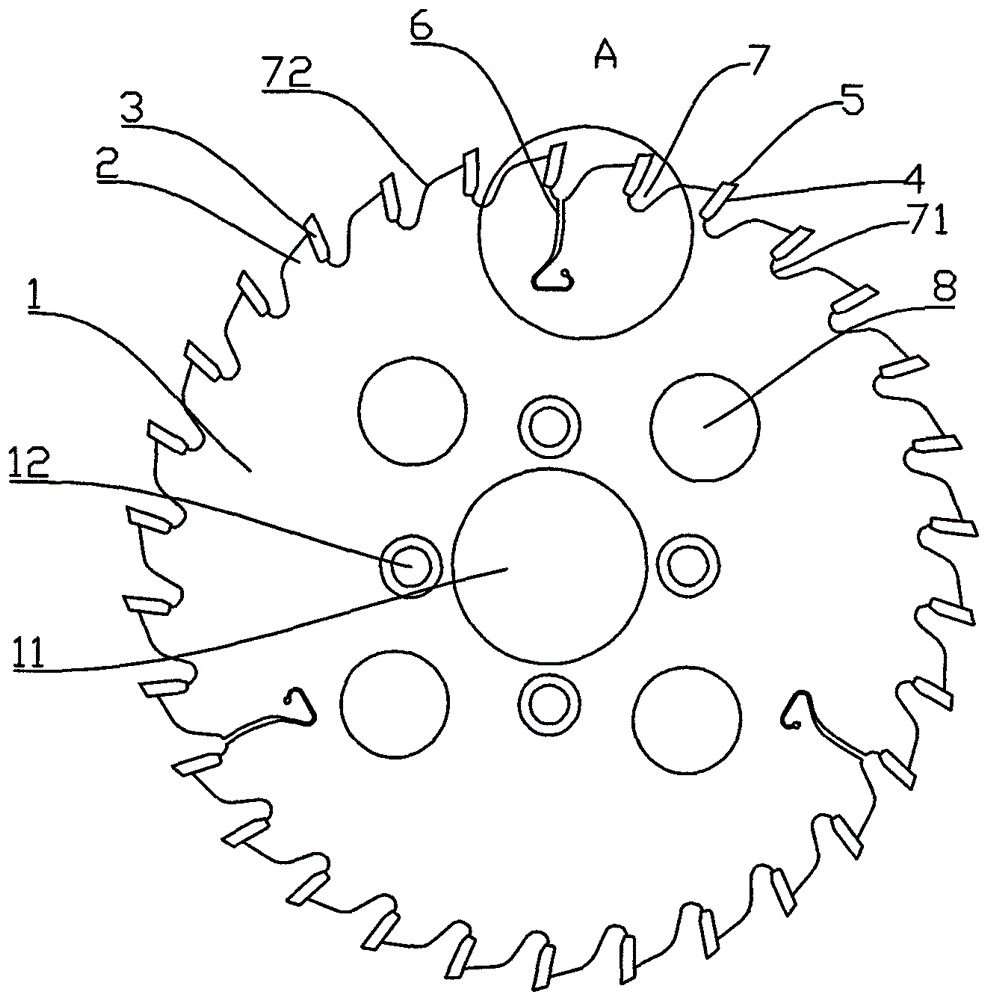

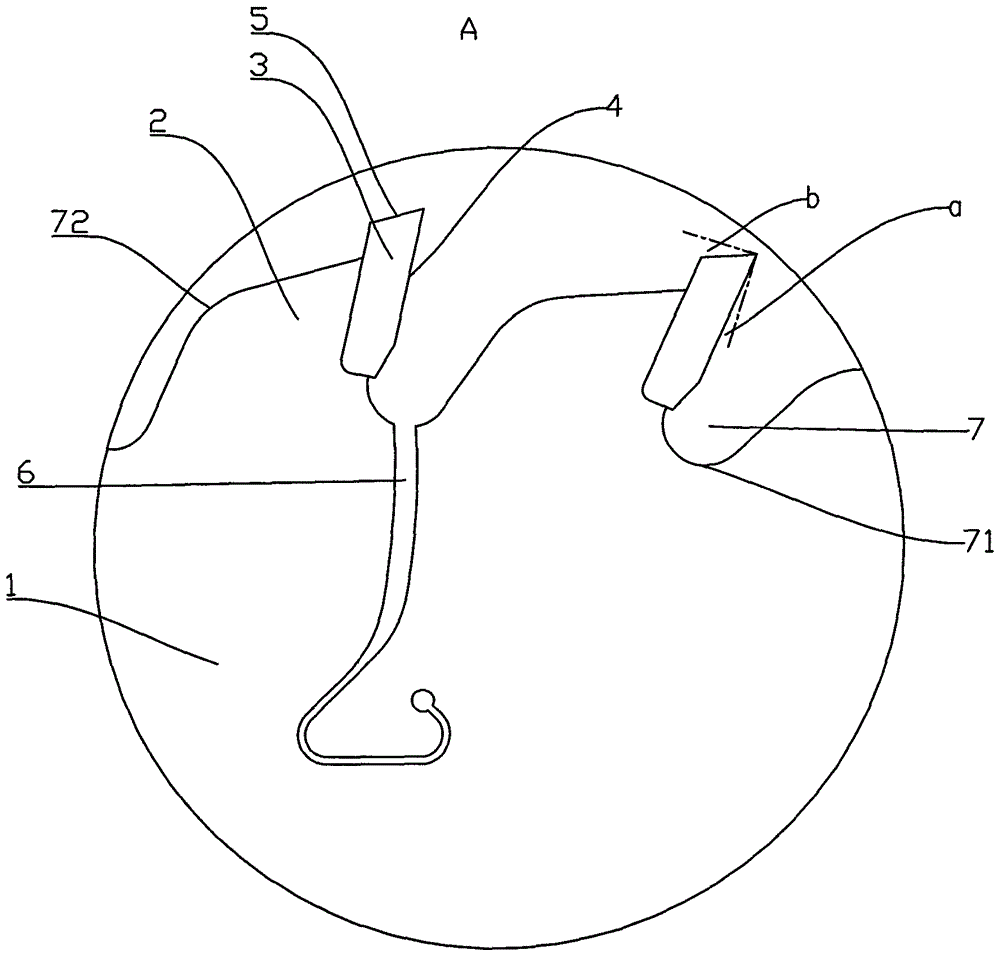

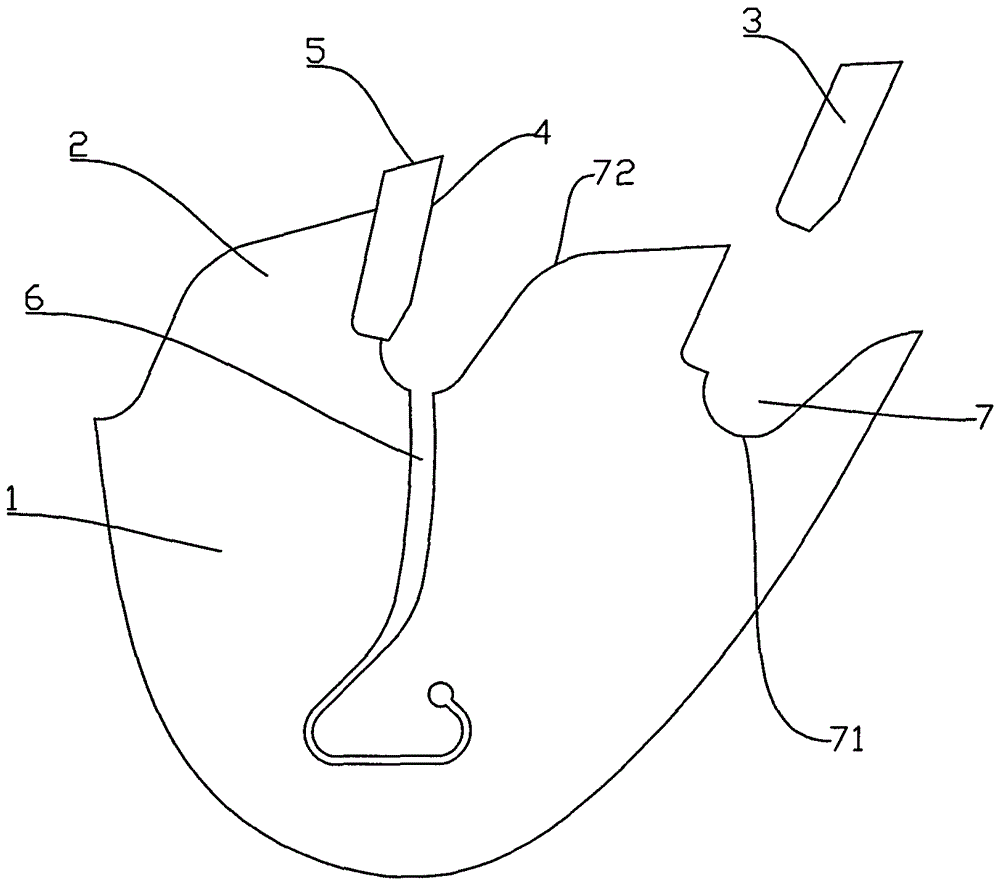

[0018] refer to Figure 1 ~ Figure 3 , the present invention is a saw blade specially used for veneer particleboard and medium density red pine board, comprising a disc-shaped saw blade base 1, 30 saw teeth 2 are arranged on the periphery of the saw blade base 1, and saw teeth 2 are provided with The cutter head 3, the adjacent cutter heads are staggered, and are respectively located on both sides of the saw blade substrate. The cutter head 3 has a main edge portion 4 and a secondary edge portion 5, and the cutter head is fixed on the saw blade substrate by welding. There is a chip removal groove 7 between the saw teeth 2, and the radial angle a between the main blade 4 and the saw blade base 1 is set to 21.5°-25.5° (the radial angle a is connected to the highest point of the main blade and the center of the saw blade base. line and the main blade itself), the tangential angle b between the auxiliary blade 5 and the saw blade base 1 is set to 20°-21° (the tangential angle a is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com