Front-end buffer device for streetcar

A technology for trams and buffer devices, applied in the direction of railway vehicle wheel guards/buffers, transportation and packaging, railway car body parts, etc., which can solve the problem of large installation space, long travel of energy-absorbing components, and installation of energy-absorbing devices The seat size and other problems can be improved to achieve the effect of improving the absorption capacity and high maintainability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The preferred technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

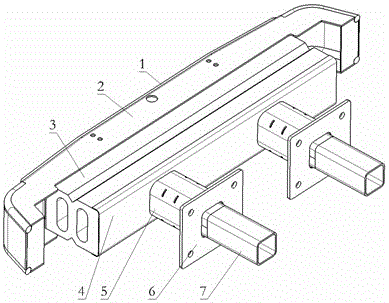

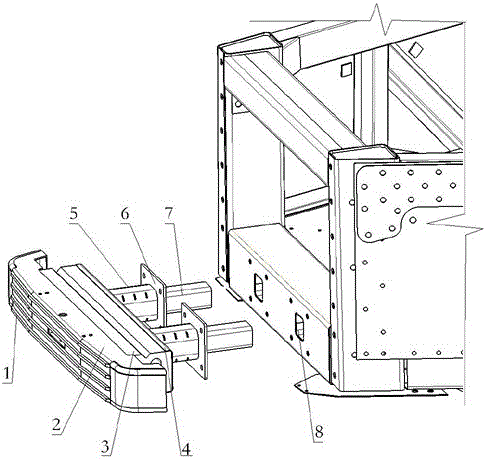

[0018] Such as figure 1 As shown, a kind of front-end buffer device for tram of the present invention comprises anti-climbing teeth 1, connecting plate 2, rubber buffer 3, energy-absorbing tube 5, mounting seat 6 and square guide bar 7, and described connecting plate 2. Located between the anti-climbing gear 1 and the rubber buffer 3, a square guide rod 7 is arranged through the rubber buffer 3. One end of the square guide rod 7 is connected to the connecting plate 2, and the other end is inserted into the Front end, also be provided with on the square guide bar 7 and be used to be fixed on the mounting seat 6 of the front end of tram, between described mounting seat 6 and rubber buffer 3, there is energy-absorbing tube 5, has induction hole on the energy-absorbing tube 5, can The pressure feed force for the initial deformation o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com