Mother liquor tank

A technology of mother liquor and tank body, applied in the field of chemical equipment, can solve the problem of not being able to discharge the mother liquor, and achieve the effects of preventing the crystallization of the mother liquor, good emptying effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

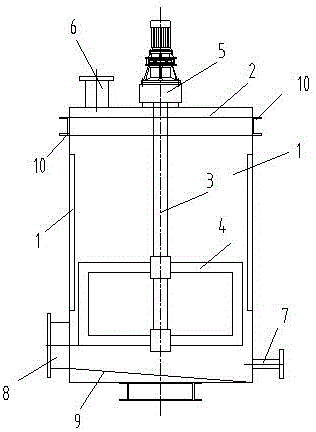

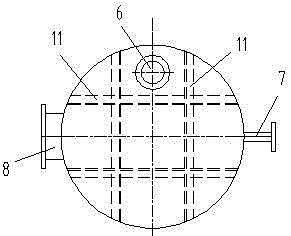

[0013] Embodiment 1: A mother liquor tank, comprising a tank body 1, a cover plate 2 is arranged at the top of the tank body 1, a stirring shaft 3 is arranged at the center of the tank body 1, a stirring paddle 4 is arranged on the stirring shaft 3, and the upper end of the stirring shaft 3 protrudes The cover plate 2 is connected to the drive motor 5, the stirring paddle 4 is a square frame, and the square frame is made of round pipes with a diameter of 57 mm. The top of the cover plate 2 is provided with a feed port 6, and the tank body 1 is provided with a discharge port 7 near the bottom. , The tank body 1 is provided with a cleaning port 8 on the other side near the bottom end. The bottom of the tank body 1 is provided with an inclined plate 9 with an inclined height of 50mm, and the height gradually decreases towards the discharge port 7. A reinforced channel steel 10 is provided on the side wall near the top end of the tank body 1 . The tank body 1 is provided with a g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com