Method for utilizing waste phosphoric acid generated in acid pickling of electronic materials

An electronic material and waste phosphoric acid technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of difficult sludge dewatering, difficult post-processing, waste of acid and alkali, etc., and achieve process parameters that are easy to control, The effect of less harm to the environment and low cost of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

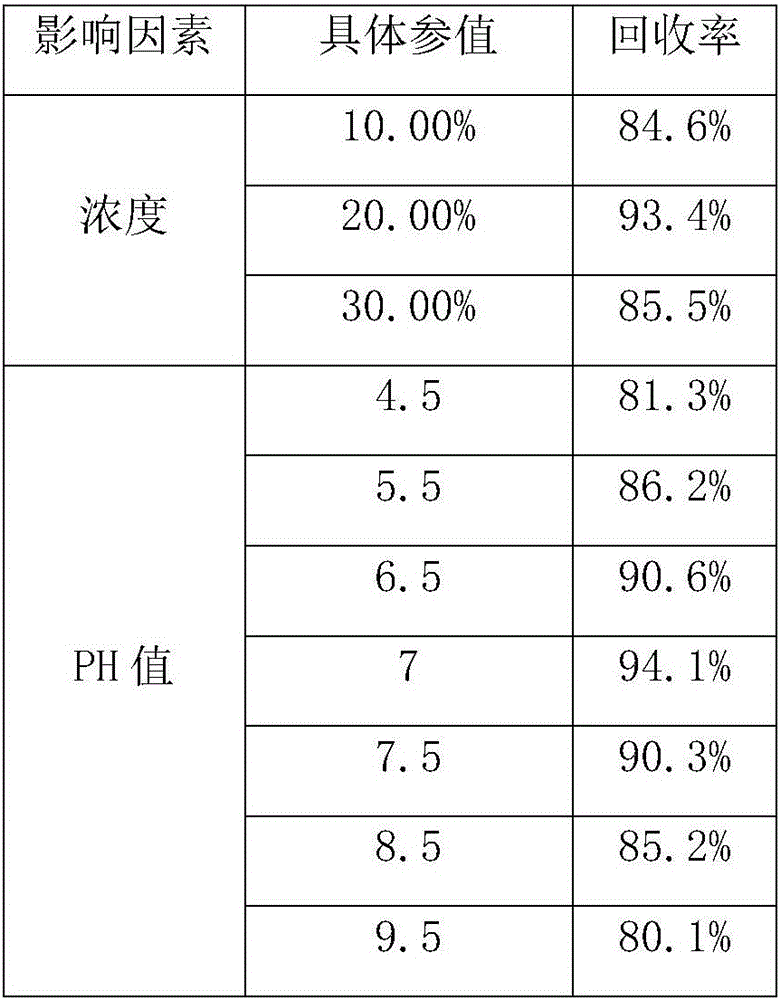

[0017] Adjust the waste phosphoric acid to a concentration of 10%-30%, divide it into 2 parts, slowly add sodium hydroxide to one part of the solution while stirring, and stir for 2 hours at room temperature until the precipitate dissolves (ph=14), then slowly dissolve it Add it to another adjusted waste phosphoric acid, control pH4.5-9.5 according to the requirements of phosphate products, stir slowly for 1 hour at room temperature, filter and wash, dry the filter residue at 105°C, the filter residue is aluminum phosphate, and the remaining When the filtrate is at 105°C, the sodium phosphate series products can be obtained by conventional crystallization.

[0018] Principle of the present invention:

[0019] al 3+ +H 3 PO 4 +4NaOH=NaAlO 2 +Na 3 PO 4

[0020] NaAlO 2 +Al 3+ +H 3 PO 4 =2AlPO 4 ↓+NaH 2 PO 4

[0021] 2NaAlO 2 +Al 3+ +H 3 PO 4 =3AlPO 4 ↓+Na 2 HPO 4

[0022] 3NaAlO 2 +Al 3+ +H 3 PO 4 = 4AlPO 4 ↓+Na 3 PO 4

[0023] h 3 PO 4 +NaOH=Na ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com