Molybdenum dioxide/nickel cobaltate classification hybrid nano-structure array and method for preparing same

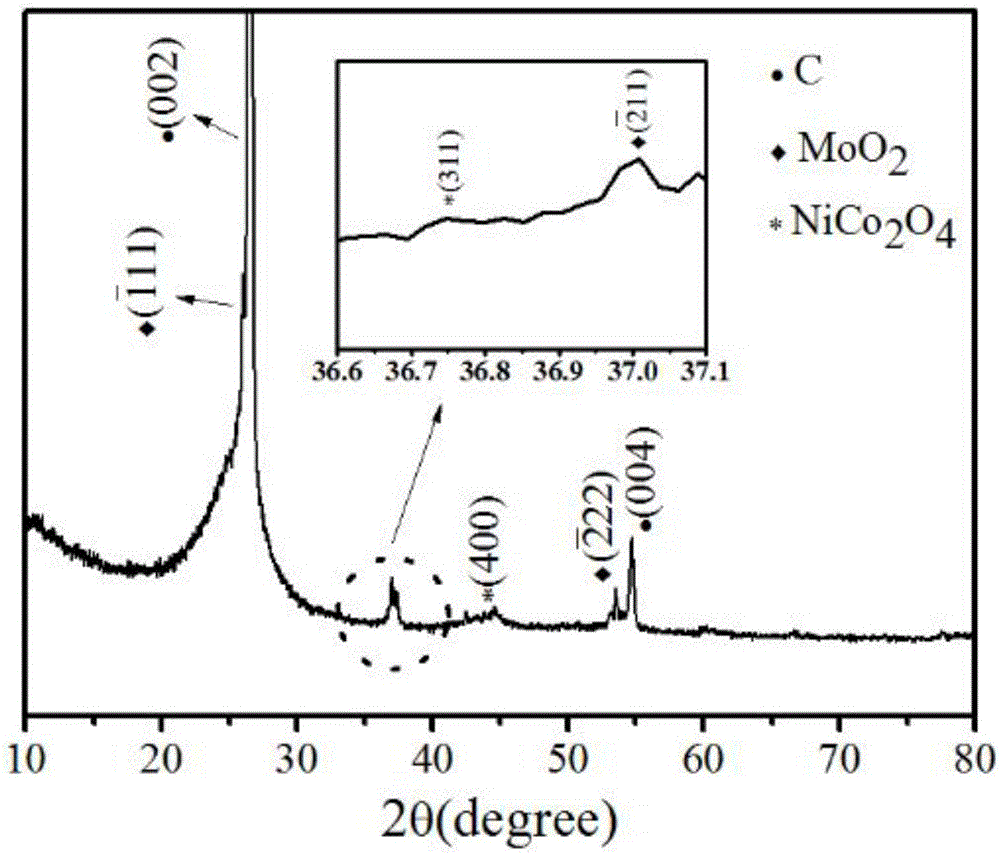

A molybdenum dioxide and nanostructure technology, applied in the field of nanostructures, can solve the problems of low cycle life and limited development, and achieve the effects of large commercial prospects, improved electrical conductivity and stable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for preparing a molybdenum dioxide / nickel cobaltate hierarchical hybrid nanostructure array, the specific steps are as follows:

[0030] (1) Put the purchased carbon fiber paper into the vacuum chamber of the magnetron sputtering deposition system, sputter 30min with the power of 40W, obtain the carbon fiber paper of sputtering metal molybdenum;

[0031] (2) Take by weighing 1.2g molybdenum-containing powder with an electronic balance and pour it into a burning boat, and pave it; the carbon fiber paper of the sputtered metal molybdenum obtained in step (1) is cut into an area of 1cm 2 -6cm 2 Thin slices, placed on the prepared burning boat;

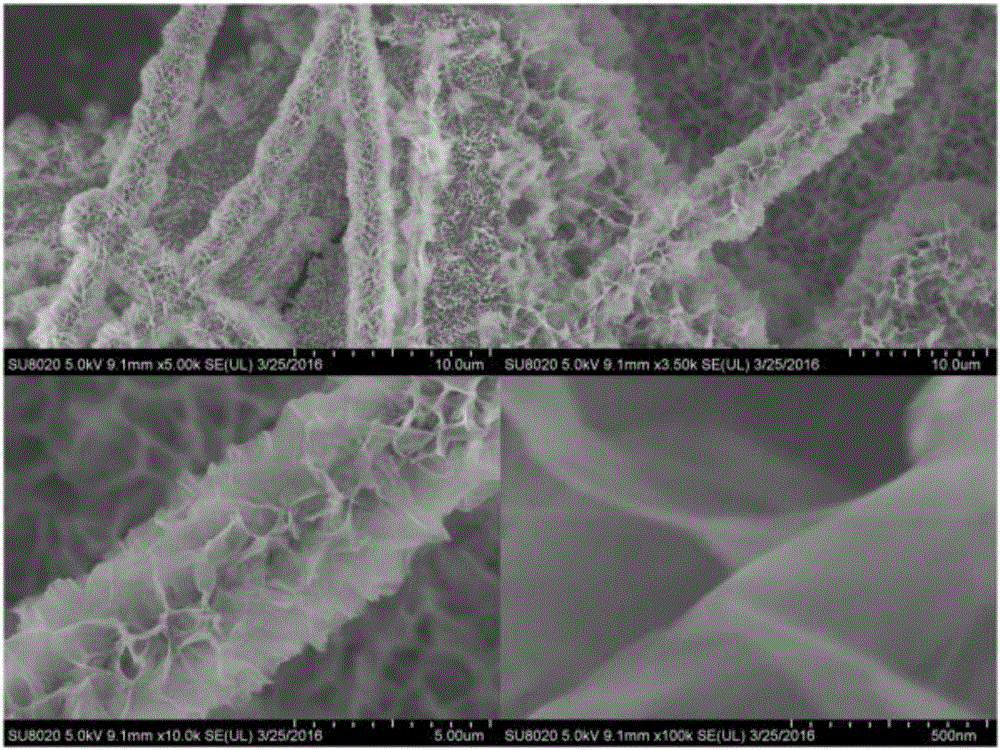

[0032] (3) Place the burning boat in step (2) in a three-temperature zone tube furnace, and perform annealing treatment at 600°C in a high-purity argon atmosphere, wherein the heating rate is 20°C / min, and the holding time is 60min. Obtain carbon fiber paper grown with molybdenum dioxide nanowire arrays;

[0033] (4) ...

Embodiment 2

[0039] A method for preparing a molybdenum dioxide / nickel cobaltate hierarchical hybrid nanostructure array, the specific steps are as follows:

[0040] (1) Put the purchased carbon fiber paper into the vacuum chamber of the magnetron sputtering deposition system, sputter 30min with the power of 40W, obtain the carbon fiber paper of sputtering metal molybdenum;

[0041] (2) Take by weighing 1.2g molybdenum-containing powder with an electronic balance and pour it into a burning boat, and pave it; the carbon fiber paper of the sputtered metal molybdenum obtained in step (1) is cut into an area of 1cm 2 -6cm 2 Thin slices, placed on the prepared burning boat;

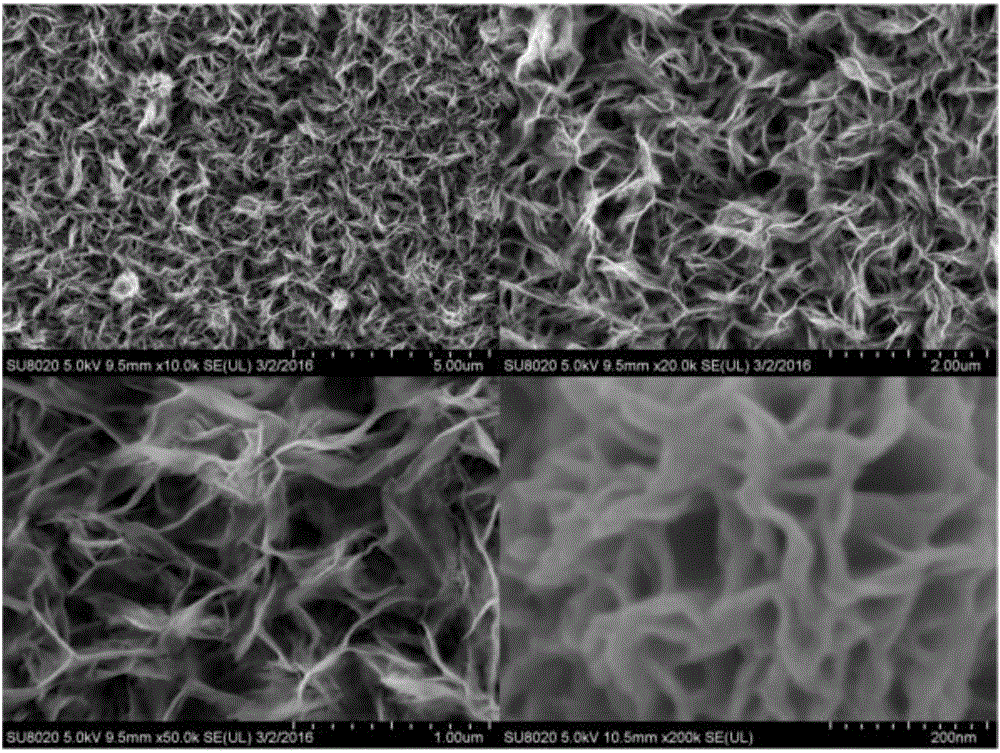

[0042] (3) Place the burning boat in step (2) in a three-temperature zone tube furnace, and perform annealing treatment at 500°C in a high-purity argon atmosphere, wherein the heating rate is 20°C / min, and the holding time is 80min. Obtain carbon fiber paper grown with molybdenum dioxide nanosheet arrays;

[0043](4) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap