Angular contact ball bearing, bearing assembly, manufacturing method and assembling method thereof

A technology for angular contact ball bearings and bearings, which is applied in the direction of rolling contact bearings, ball bearings, bearing components, etc., which can solve the problems of complex production processes, affecting bearing accuracy, and high production costs, and achieve the effect of avoiding grinding and reducing processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1 of the angular contact ball bearing assembly method of the present invention includes the following steps:

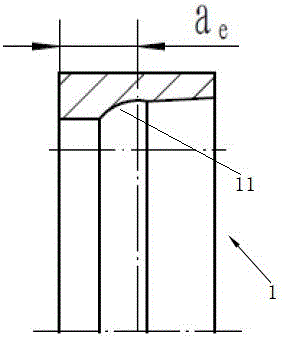

[0028] The first step is to design the position a of the outer ring groove 11 on the outer ring 1 of the angular contact ball bearing e so that it satisfies formula 1: a e =B / 2+(R i +R e -D w )*sinα+δ;

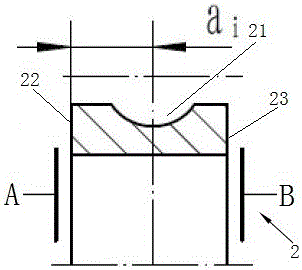

[0029] In the second step, the first end and the second end of the inner ring 2 of the angular contact ball bearing are marked as the A end face 22 and the B end face 23 respectively, and the position a of the inner ring groove 21 of the angular contact ball bearing is designed i Make it satisfy formula 2: a i =B / 2+β, the value of β in the formula takes any value between -0.1 and 0 according to the accuracy of the machine tool;

[0030] In the third step, take T=B+2*(R i +R e -D w )*sinα-2*a e , adjust the δ value in the first step so that the T value is -2δ a , Record the above formula as formula 3;

[0031] The fourth step is to proce...

Embodiment 2

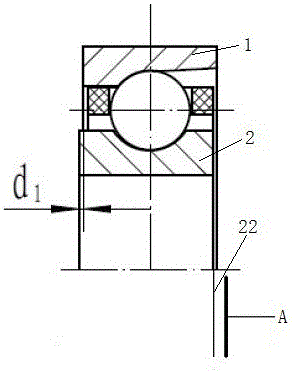

[0039] The difference between Embodiment 2 of the method for assembling angular contact ball bearings of the present invention and Embodiment 1 of the method for assembling angular contact ball bearings is only that in the sixth step, the protrusion amount of the finished bearing manufactured in the fifth step For measurement, select angular contact ball bearings with opposite signs of protrusion values and equal absolute values for back-to-back assembly to form a bearing assembly.

[0040] Specifically, when the bearings need to be assembled back-to-back, measure the bearing I and the bearing II respectively to find out a bearing I and a bearing II, and make the protruding values of the two bearings found have opposite signs and absolute The values are equal, and then the two bearings are assembled back-to-back. After the assembly, the wide-side end faces of the outer rings of the two bearings face each other so that the load line of the two bearings is "O"-shaped.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com