Clean carbon heating and heat supply machine with heat storage and combustion intensity buffer mode

A technology with high combustion intensity and cleanliness, applied in lighting and heating equipment, dryers, drying, etc., can solve the problems of incomplete heat exchange and low thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

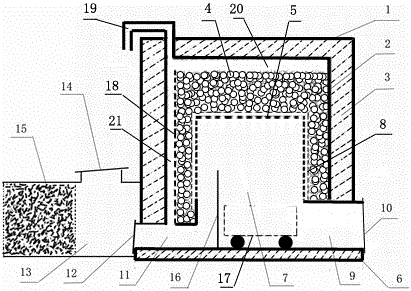

[0019] The embodiments will be described below in conjunction with the accompanying drawings.

[0020] The clean charcoal heating heat supply machine with heat storage and combustion intensity buffering method includes inner (2) and outer box (1), and its technical features are: it is set between the outer box (1) and the inner box (2) heat insulation layer (3); in the inner box (2), the space between the load-bearing bracket (5) and the base (6) constitutes a charcoal combustion chamber (7), and the isolation net (8) is installed on the load-bearing bracket (5 ), pile up heat storage particles (4) between the isolation net (8) and the inner box (2); the air inlet (9) is installed at the bottom of the box or on one side of the bottom, and is connected with the charcoal combustion chamber (7) The air inlet is equipped with an air inlet door (10), and the air inlet door (10) can control the degree of opening and closing; the air outlet (11) is arranged at the bottom or one side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com