Environment-protecting and energy-saving reverse discharge type biomass gasifier

An environmentally friendly, energy-saving, reverse exhaust technology, applied in the field of heating furnaces, can solve problems such as waste of heat energy, and achieve the effect of prolonging the time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

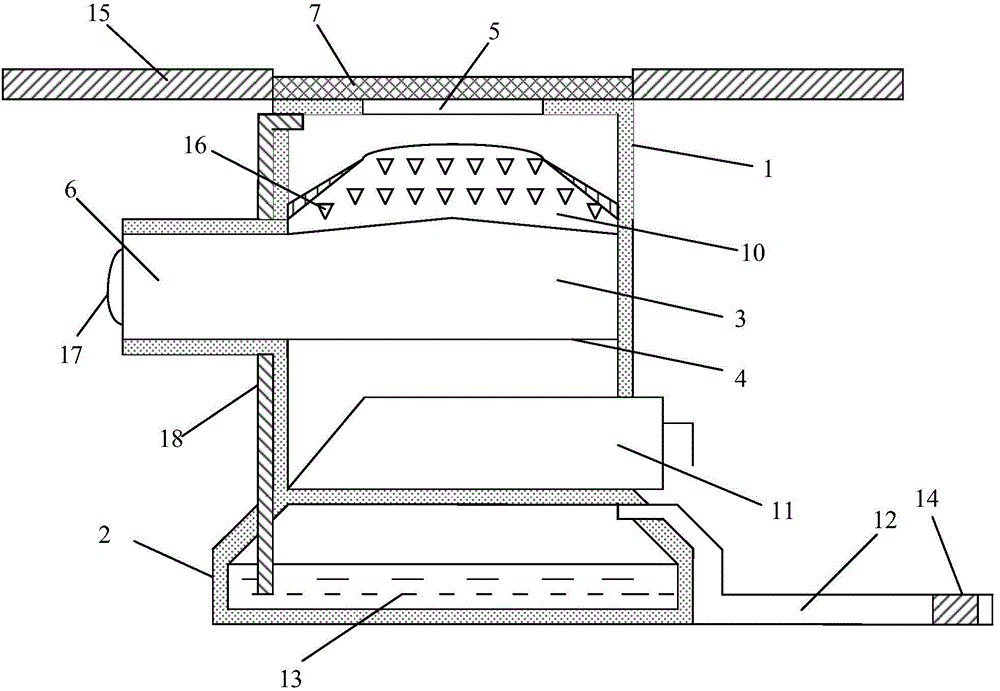

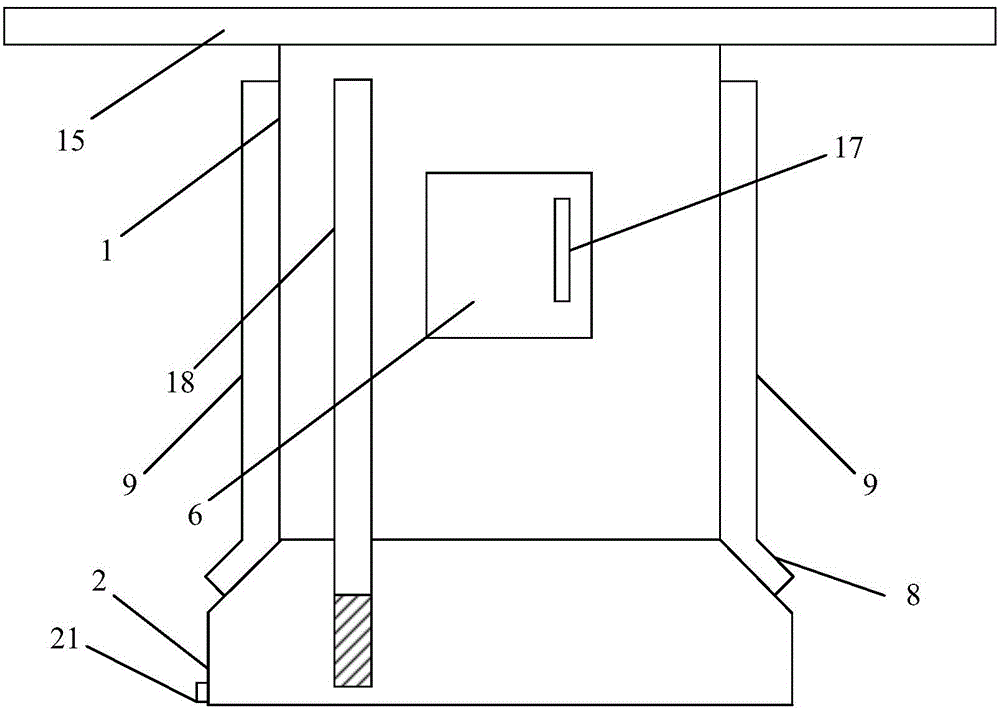

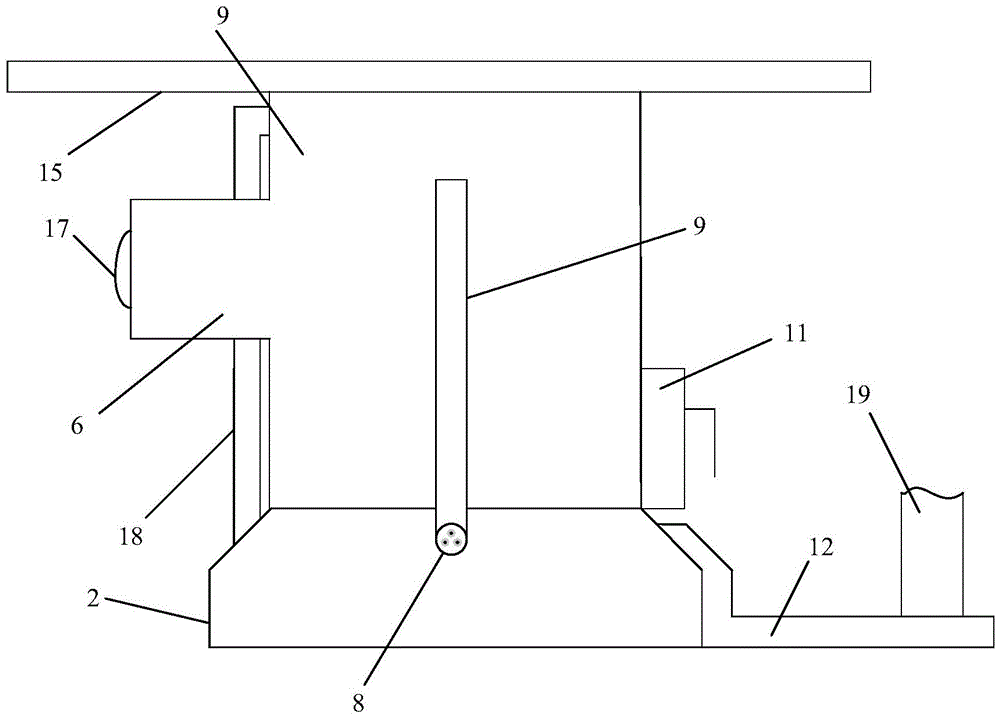

[0028] The present invention is described in further detail below in conjunction with accompanying drawing:

[0029] see Figure 1 to Figure 4 , the present invention comprises a furnace body 1, the side of the furnace body 1 is provided with a feed inlet 6, the top is provided with a stove table 15, and the bottom is installed on a furnace base 2; the top of the furnace body 1 is provided with a furnace mouth 5, and the furnace mouth 5 is provided with Fireproof cover7. Inside the furnace body 1 is a furnace, which includes a lower primary combustion chamber 3 for burning solid or biomass fuels and an upper secondary combustion chamber 10 for burning combustible gases produced by burning solid or biomass fuels; The combustion chamber 3 is oval, and the secondary combustion chamber 10 is conical. Several secondary oxygen supply inlets 16 are provided on the secondary combustion chamber 10 . The bottom of the primary combustion chamber 3 is provided with a furnace bridge too...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com