Low-impulse efficient pressure-resistant oil gas cooler

An oil-air cooler, high-efficiency technology, applied in the direction of indirect heat exchangers, heat exchanger shells, heat exchanger sealing devices, etc., can solve the problems of oil-air coolers that cannot be installed normally, limit the application of oil-air coolers, and have large volumes of oil-air coolers To prevent leakage, reduce the risk of leakage, and increase reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific embodiments of the present invention will be described below in conjunction with the drawings.

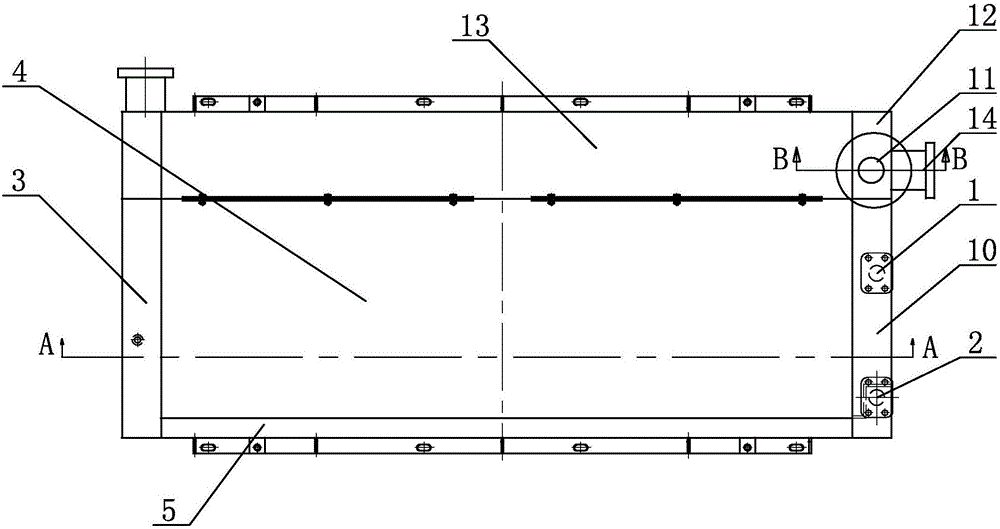

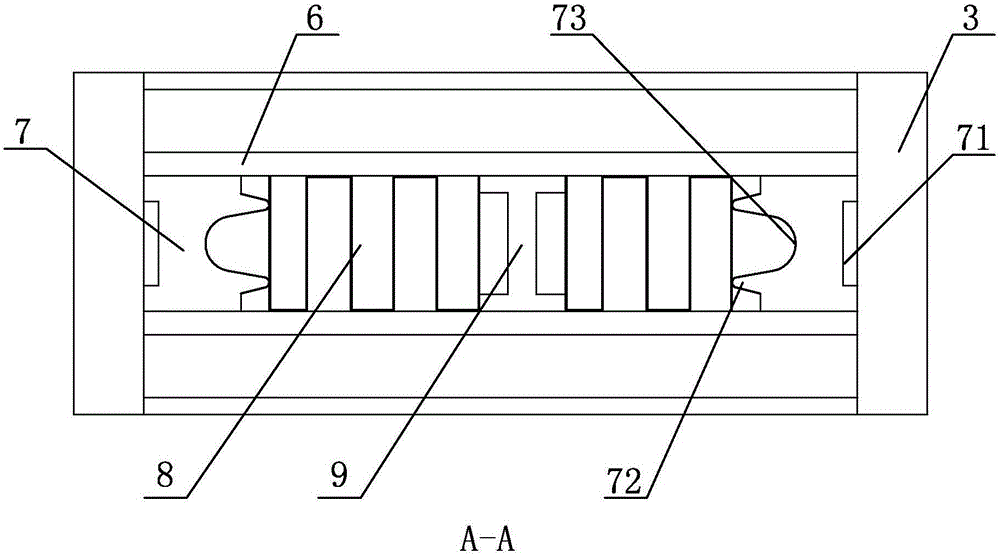

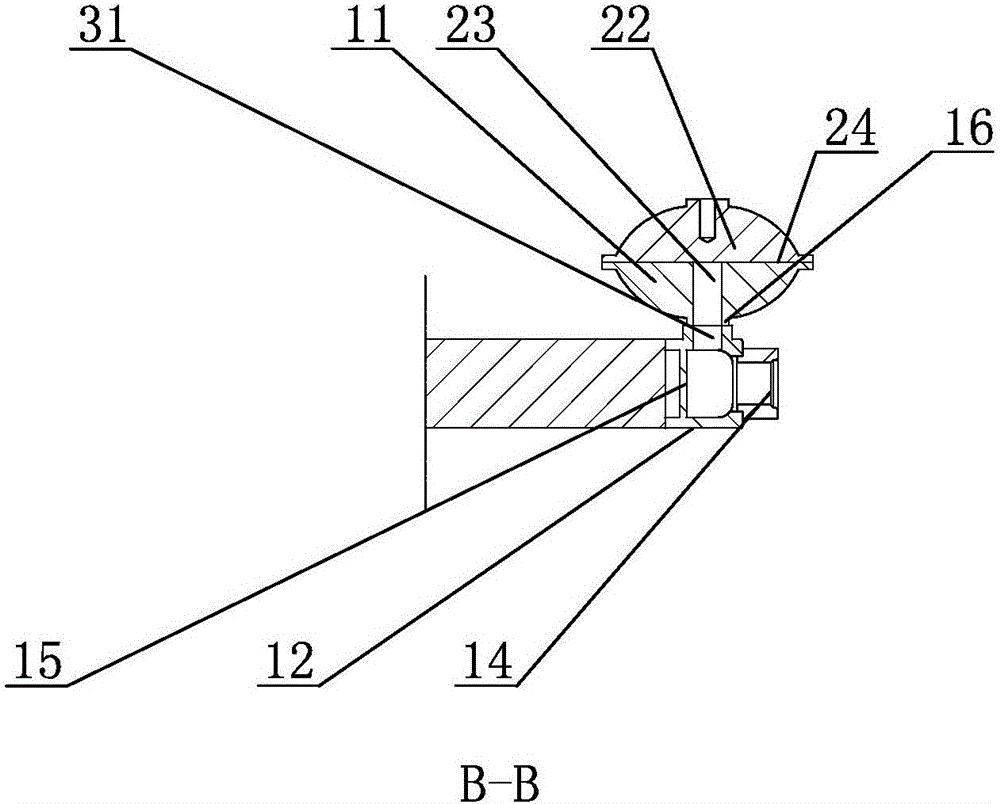

[0016] Such as Figure 1 to Figure 3 As shown, the present invention includes a core body 4, the two ends of the core body 4 are respectively welded with a left head 3 and a right head 10, the oil and gas inlet 1 and the oil and gas outlet 2 are both located on the right head 10, in the right head 10. , The oil and gas inlet 1 and the oil and gas outlet 2 are closed by a partition plate to avoid the communication between the oil and gas inlets and outlets; a bypass pipe 5 is installed on the side wall of the core 4, and the left head 3 communicates with the oil and gas outlet 2 through the bypass pipe 5, and the oil The oil and gas inlet 1 enters and flows back from the oil and gas outlet 2 through the bypass pipe 5 to form a one-way circuit, which solves the problem of inability to install and use because the access is on different sides in actual use; the core 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com