A smoke wire flow display control device

A technology of flow display and control device, applied in measurement devices, aerodynamic tests, instruments, etc., can solve the problems of easy burnout, high working voltage of metal wires, unsatisfactory effect, etc., to achieve clear settings and improve success rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

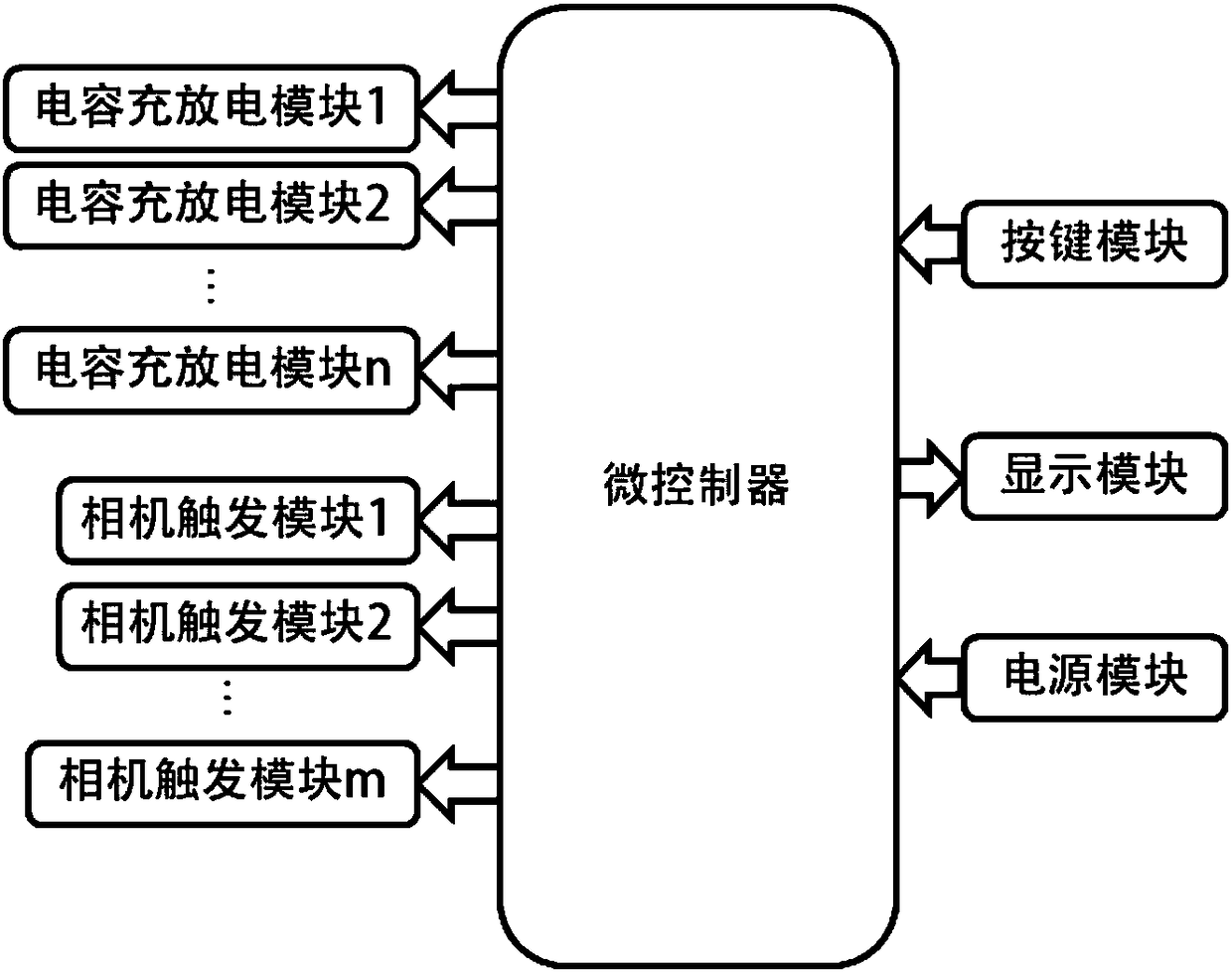

[0031] figure 1 It is a module schematic diagram of a smoke line flow display control device. In the figure, the smoke line flow display control device includes a power supply module, a button module, a display module, a capacitor charging and discharging module and a camera trigger module.

[0032] The working process is as follows:

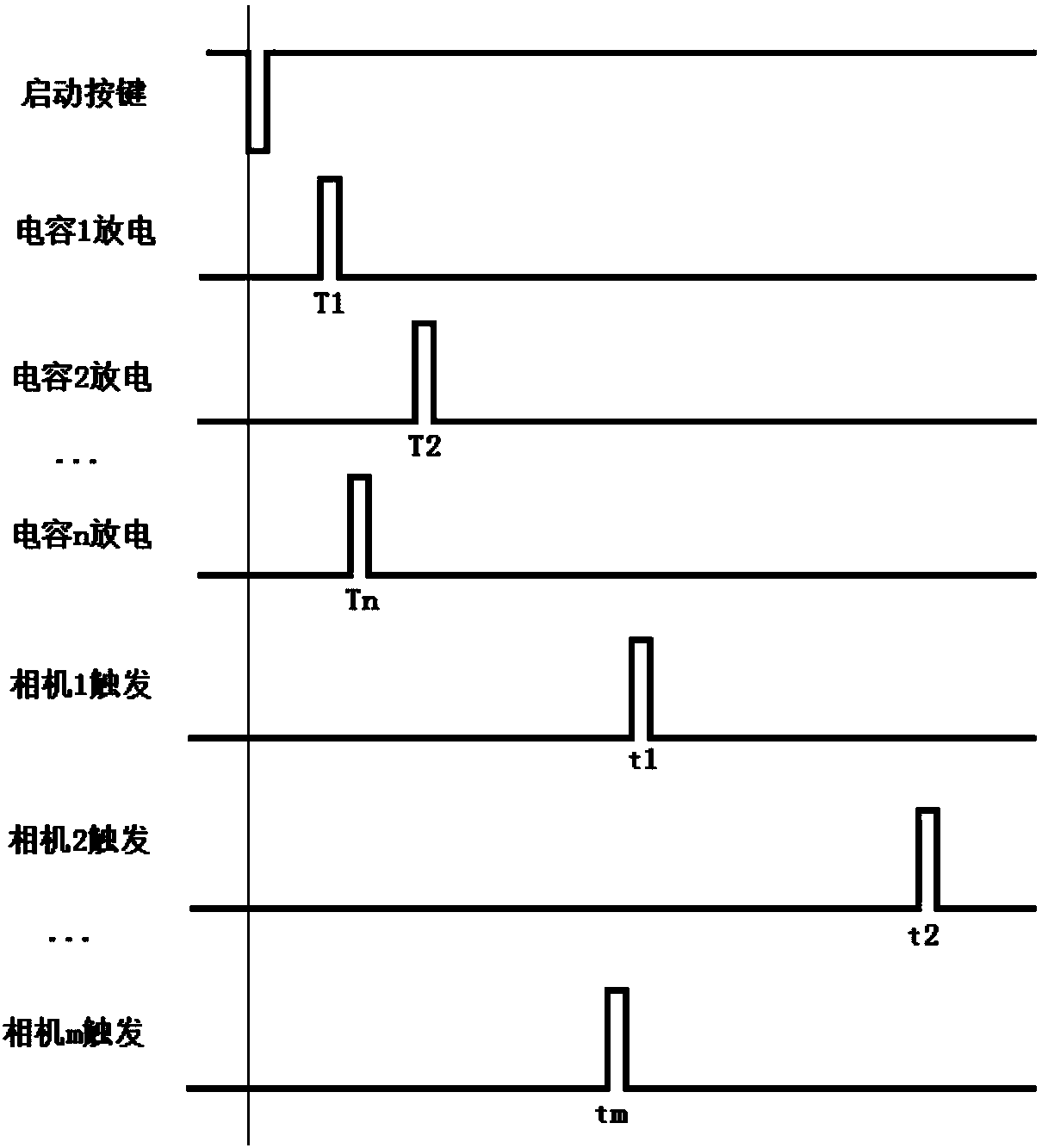

[0033] After the device is powered on, first use the parameter addition and subtraction, parameter selection and confirmation buttons on the button module to set the voltage of the capacitor charging and discharging module, the discharging time of the charging and discharging module and the triggering time of the camera.

[0034] Press the charging button on the button module, and the device will charge the capacitor charging and discharging module to the set voltage at this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com