Brightness enhancement film with intermittent whole vertical wave structure

A brightness-enhancing film and overall technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of low brightness and poor anti-adsorption effect of the brightness-enhancing film, and achieve high brightness and good anti-adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

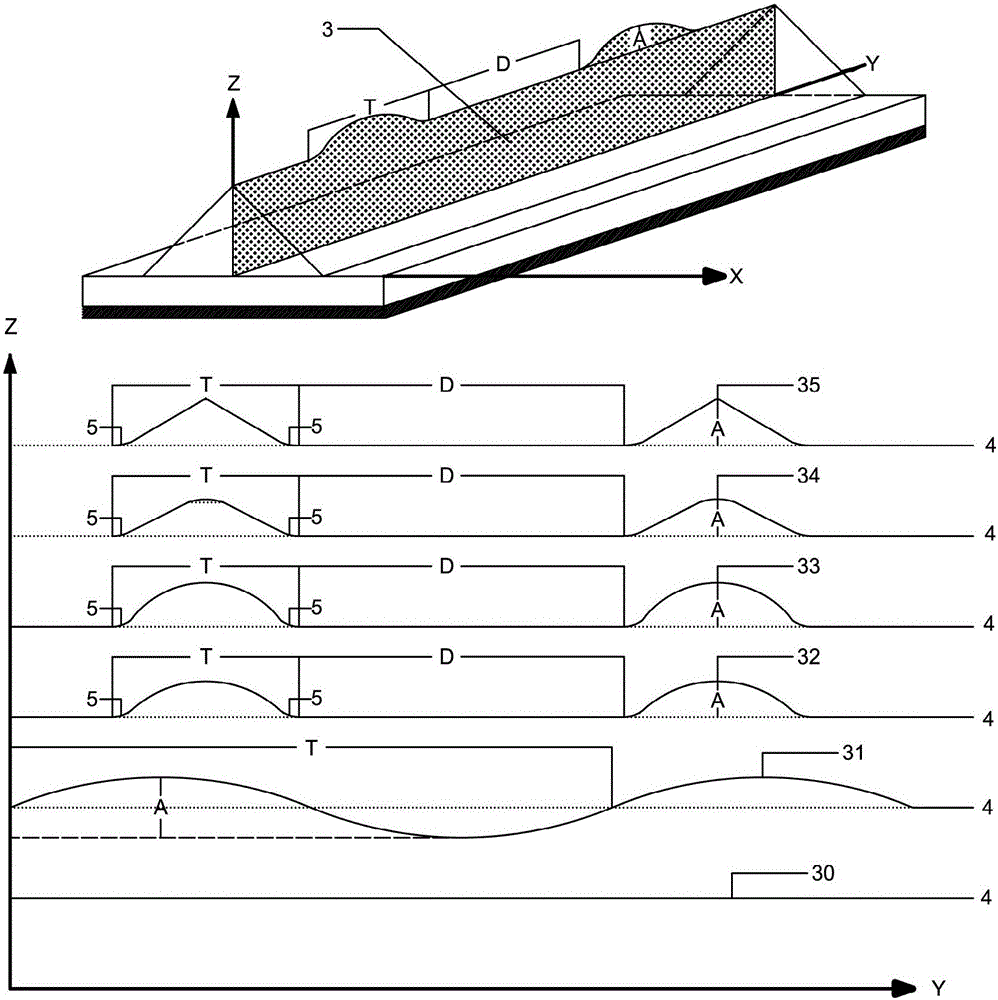

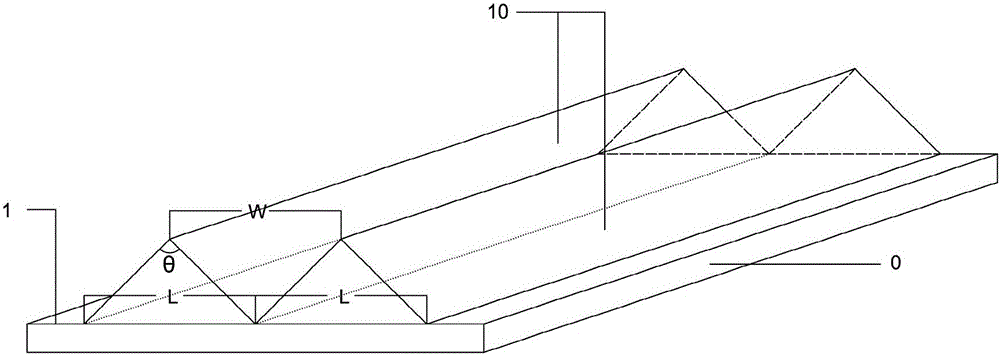

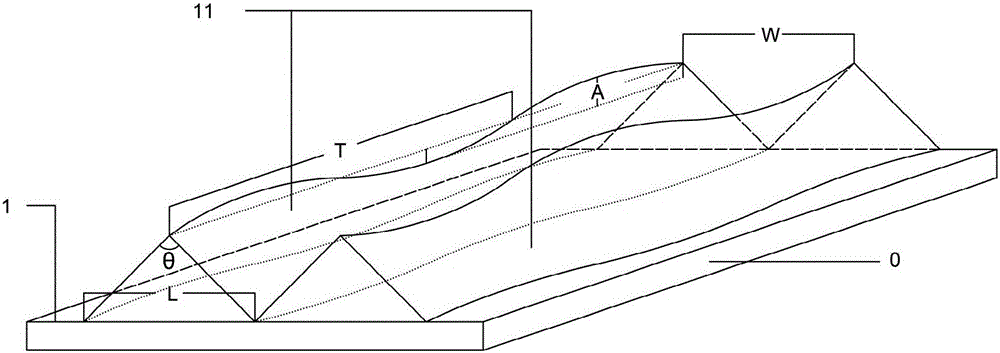

[0082] Such as Figure 4As shown, the brightness enhancement film with an intermittent integral up and down structure provided by the present invention includes a substrate layer 0 and a structural layer 1, wherein the structural layer 1 includes a tiled prism structure, and its cross-section is an isosceles triangle extending intermittently along the longitudinal direction of the prism. Jitter, the trajectory of the triangular vertices along the longitudinal section is half cycle of the sinusoidal convex shape. The prism spacing W is 24 μm, the apex angle θ of the prism is 90 degrees, the bottom edge of the prism in the shaking interval is L=W, the shaking period T is 250 μm, the shaking interval D is 25 times of the shaking period T, and the height difference within the shaking period is A is 2.5 μm. The thickness of the substrate layer is 0.1mm, and the material is PET. The prism material of the structural layer is light curing resin polyurethane acrylate.

Embodiment 2

[0084] For the brightness-enhancing film with an intermittent overall up-and-down shaking structure provided in Example 1, the prism spacing W is 10 μm.

Embodiment 3

[0086] For the brightness-enhancing film with an intermittent overall up-and-down shaking structure provided in Example 1, the distance W between the prisms is 100 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com