Battery winding products and disposable lithium metal batteries

A battery coil and metal conduction technology, applied in the field of battery winding products and disposable lithium metal batteries, can solve the problems of wasting negative electrode sheet materials, increasing difficulty, and negative electrode sheet fusing, etc., and achieves the effect of improving electrical performance indicators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

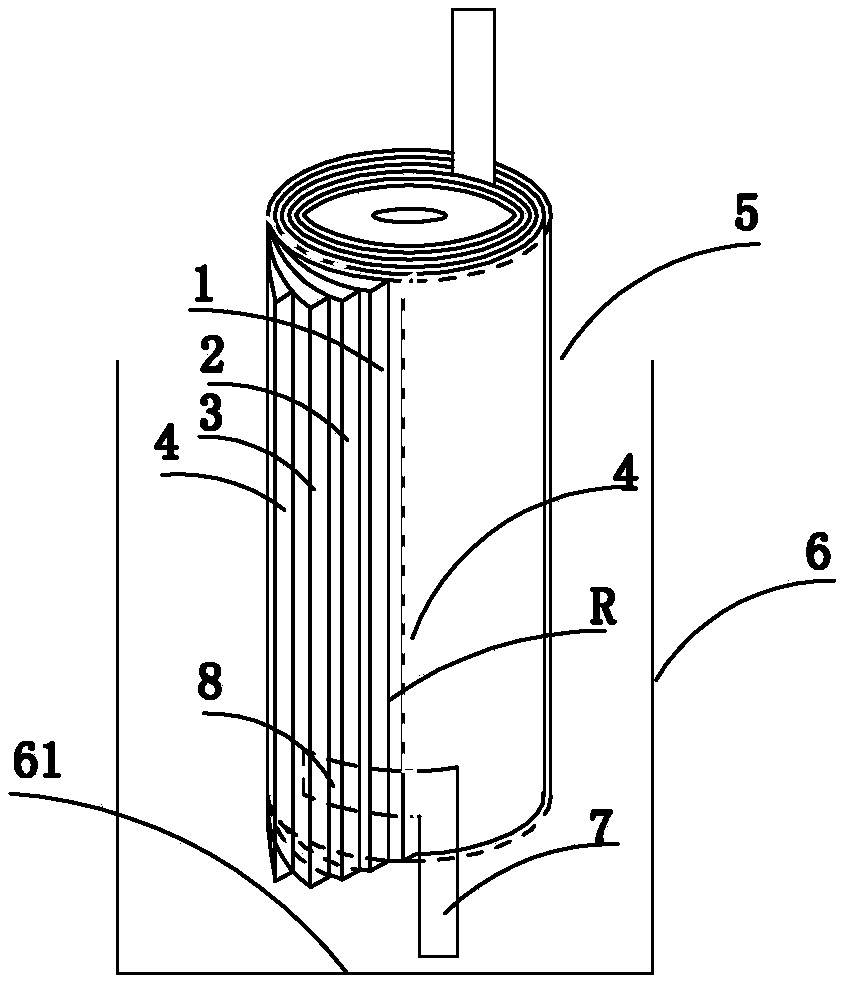

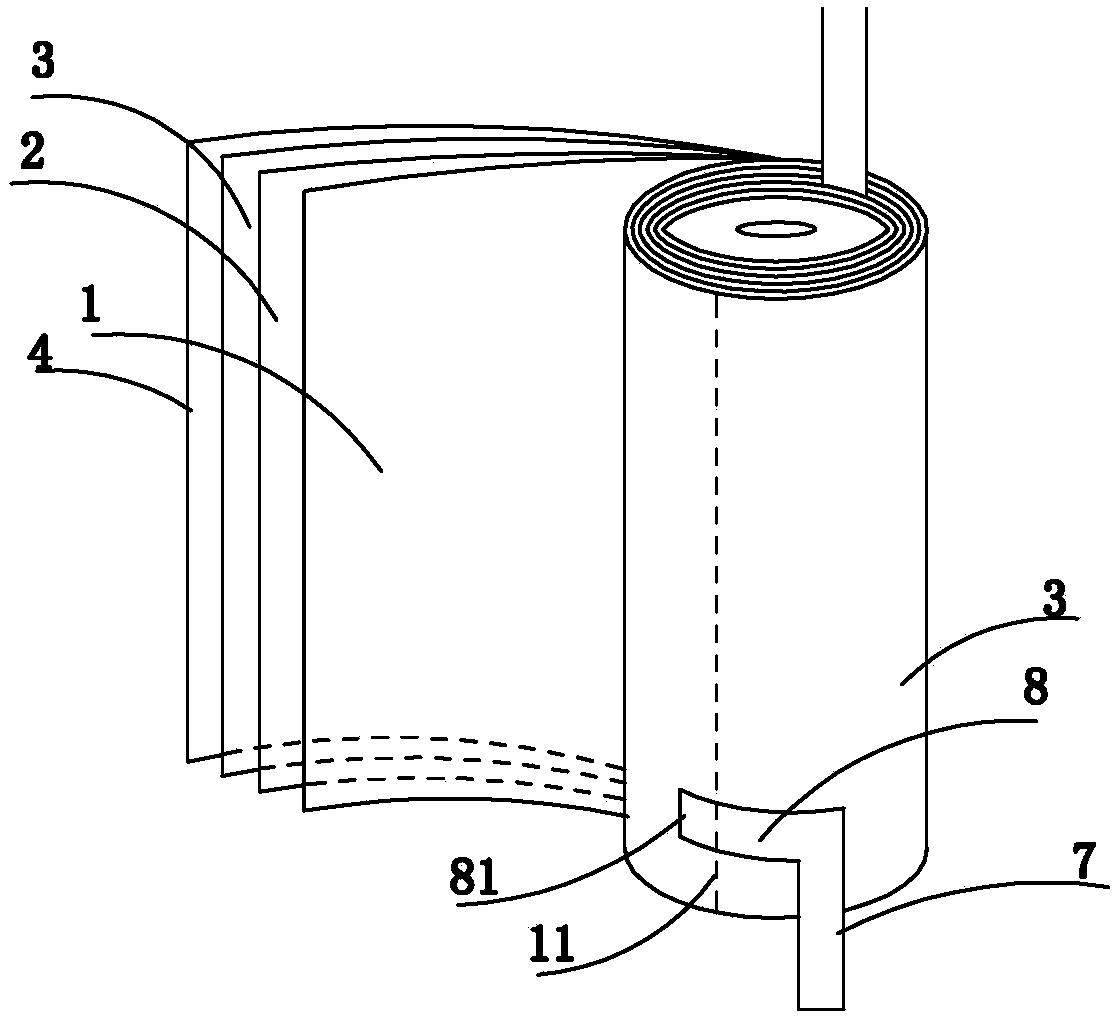

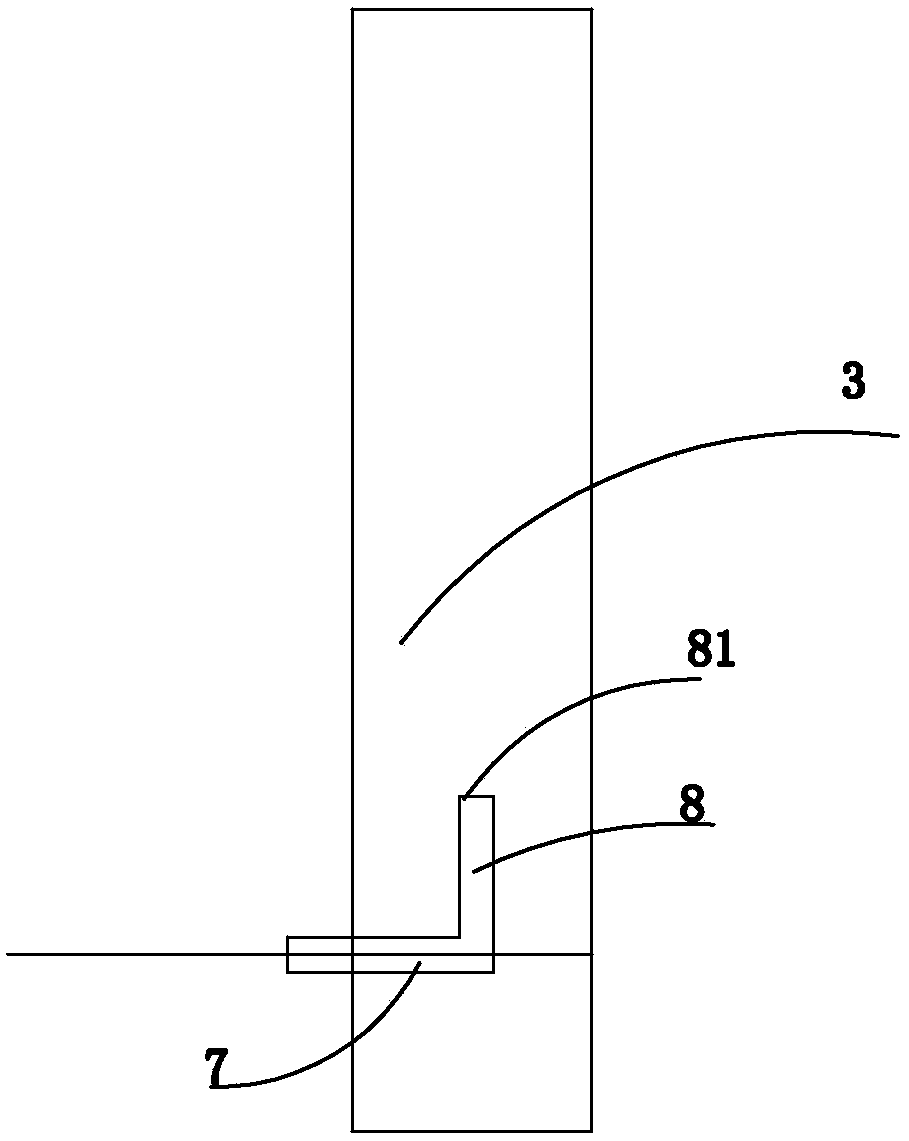

[0029] Such as figure 1 and figure 2 As shown, the battery winding product includes a combination composed of the positive electrode sheet 1 of the inner layer, the first separator paper 2, the negative electrode sheet 3 and the second separator paper 4 of the outer layer in sequence, and the combination is wound into a cylindrical roll Winding body 5, negative electrode sheet 3 is connected with the negative electrode tab 7 parallel to the center line of winding body 5 and extending to the bottom 61 of steel shell 6, the end cutout 11 of positive electrode sheet 1 is connected to the inner side of the end cutout 11 The negative electrode tab 7 on the negative electrode sheet 3 has a certain distance, and the negative electrode tab 7 is integrally provided with a metal conductor 8 whose extending direction is consistent with the winding dire...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com