Pneumatic tire

A technology of pneumatic tires and tires, which is applied to pneumatic tires, reinforcement layers of pneumatic tires, special tires, etc., can solve the problems of difficult control stability, low fuel consumption performance, increased fuel consumption performance, and reduced side reaction force. The effect of reducing tire weight and rolling resistance, improving fuel consumption, and reducing tire weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

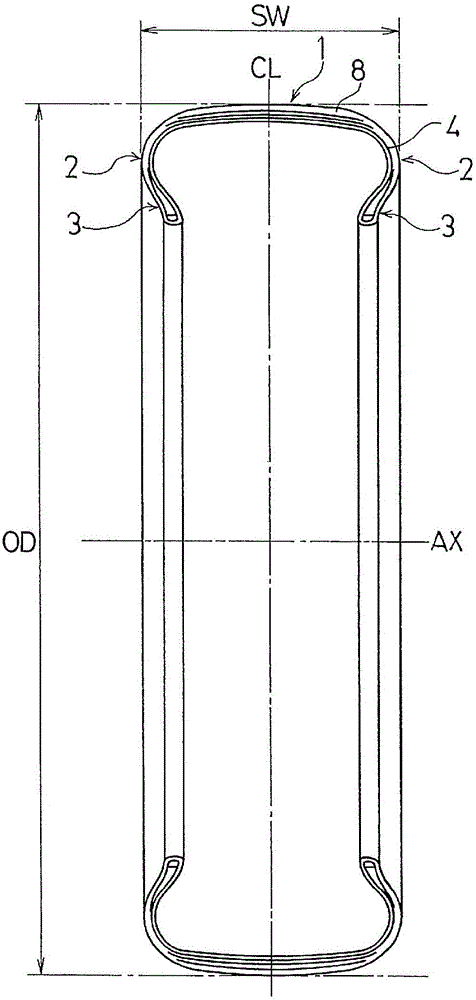

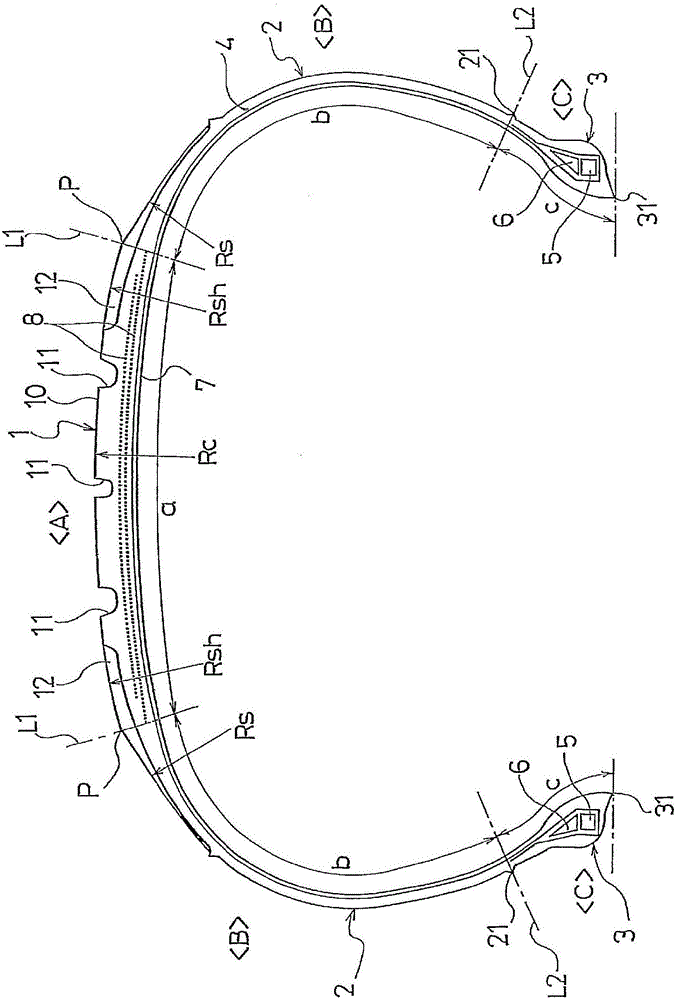

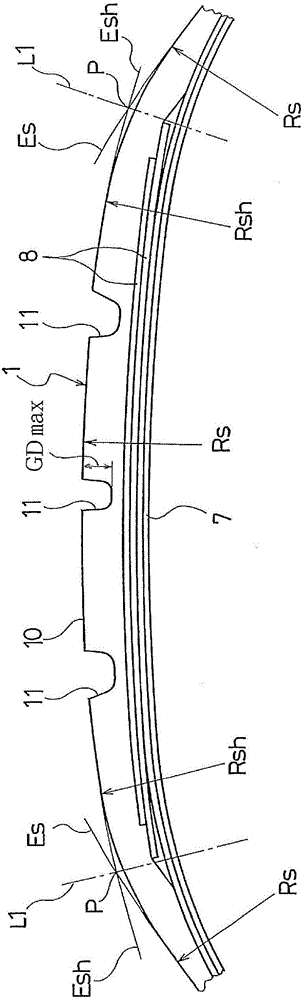

[0094] When the tire size is 195 / 65R15 or 155 / 55R20, it is equipped with a tread portion extending in the tire circumferential direction in an annular shape, a pair of sidewall portions disposed on both sides of the tread portion, and a tire disposed on these sidewall portions. A pair of bead portions on the inner side in the tire radial direction, a carcass layer is bridged between the pair of bead portions, and a pneumatic tire is provided with an air permeation prevention layer on the inner surface of the tire. The ratio SW / OD of the outer diameter OD, the cross-sectional area SA, SB, SC from the first area to the third area (mm 2 ) and the peripheral length a, b, c (mm) calculated ratio SA / a, SB / b, SC / c, groove area ratio GR, maximum groove depth GDmax of the main groove, inclined reinforcement layer (number of layers, reinforcement curtain The inclination angle of the thread with respect to the tire circumferential direction), the circumferential reinforcement layer (pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com