Photocatalytic Micro-Gas-Liquid Bubble Column Reactor

A technology of photocatalysis and bubble tower, which is applied in the field of photocatalysis, can solve the problems of enhanced processing capacity, difficulty in separation and recovery, and long reaction time, and achieve the effects of large processing capacity, accelerated reaction rate, and improved mass transfer coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

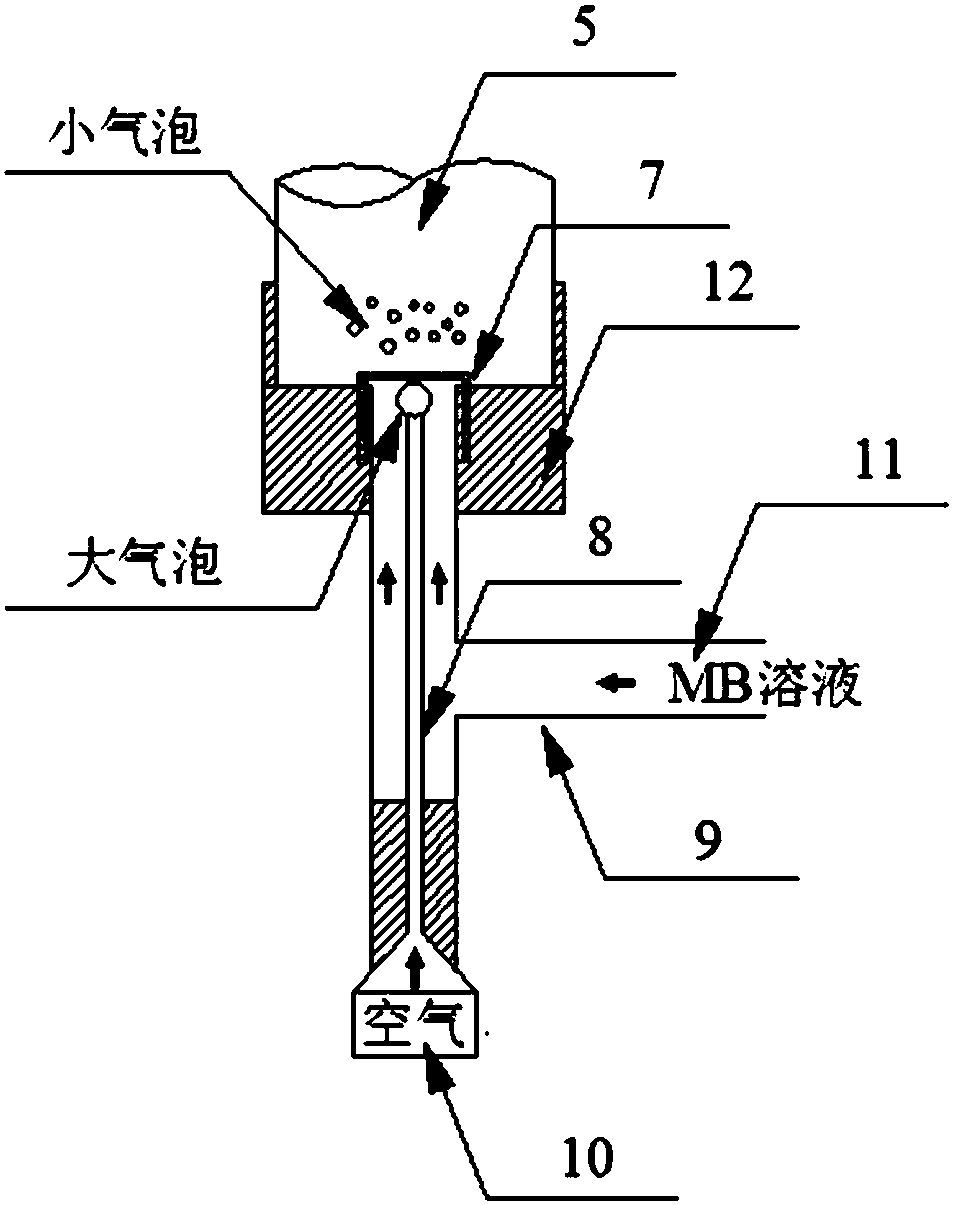

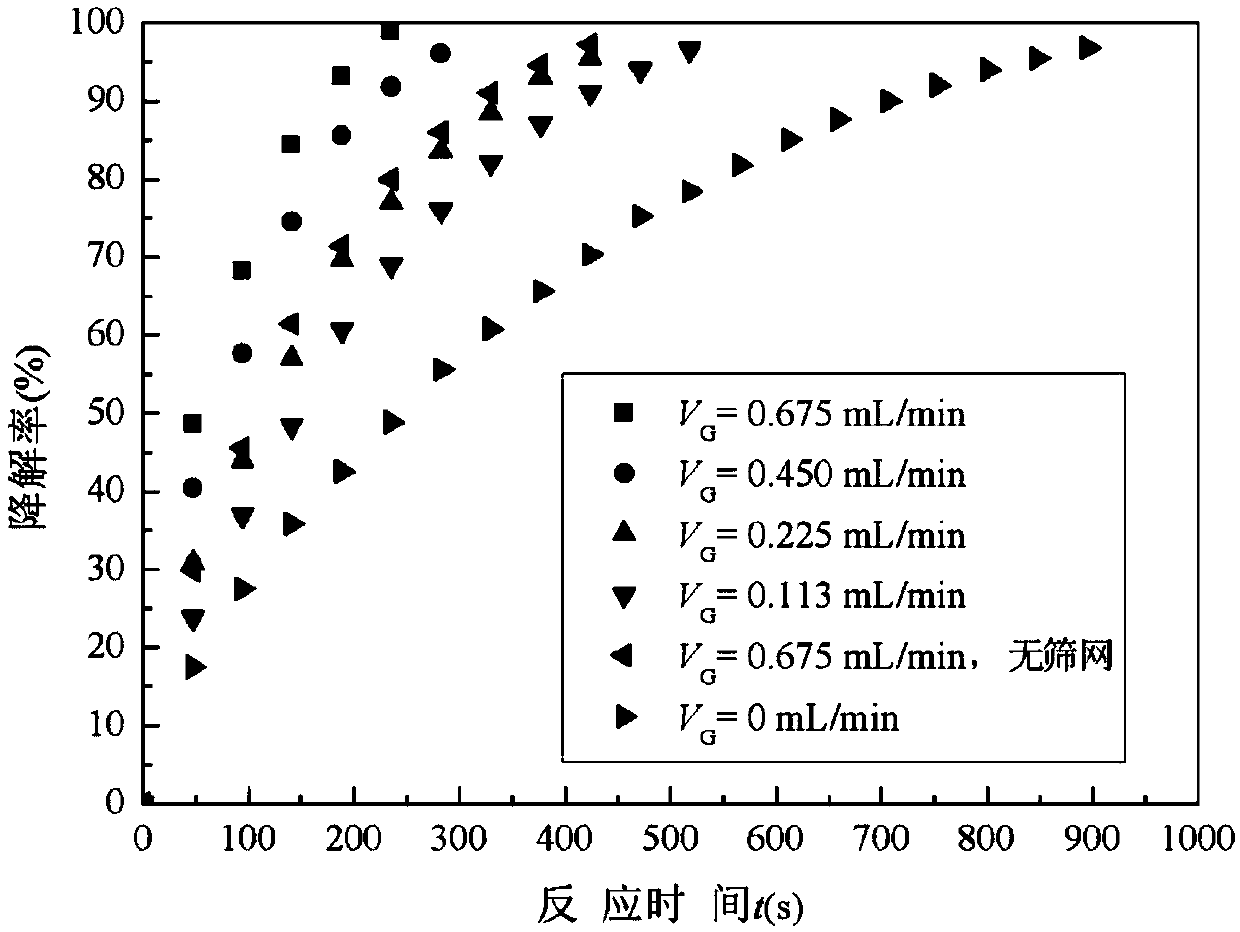

[0022] Methylene blue (MB) was selected as the reactant to investigate the photocatalytic activity of the photocatalytic micro gas-liquid bubble column reactor. The inner diameter of the quartz tube is 3mm, the length is 100mm, the length of the reflector is 150mm, the inner diameter of the T-shaped tee is 2mm, the inner diameter of the needle tube 8 is 0.13mm, and the aperture of the screen is 0.053mm. During the operation of the photocatalytic micro-bubble column reactor, the power of the xenon lamp is 200W, and the initial concentration of the MB solution is C 0 20mg·L -1 , the flow rate Q is 0.900mL·min -1 , the flow rate of air V G 0.013, 0.225, 0.450 and 0.675mL min -1 , corresponding to the superficial liquid velocity u L 0.027, 0.053, 1.06 and 1.59mm s respectively -1 . The large air bubbles at the top of the needle tube 8 are quickly separated from the needle tube 8 and passed through the screen 7 under the impetus of the liquid in the needle tube and the three-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com