Hull plate paint-spraying wall climbing vehicle device carried on aerial lift vehicle and work method thereof

A technology for hull panels and elevated vehicles, which is applied in the direction of spraying devices, etc., which can solve the problems of prone to danger, fatigue of operators in spraying work, and high work intensity, so as to reduce the number of people and work intensity, reduce the risk of falling, and improve safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

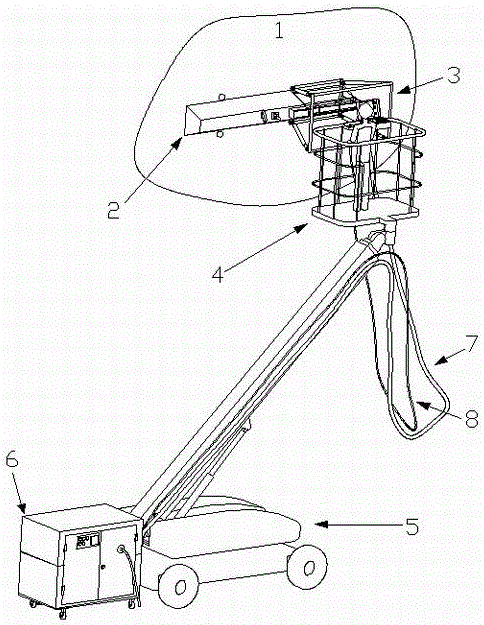

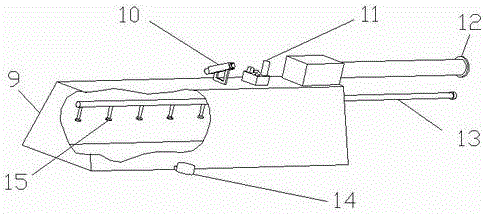

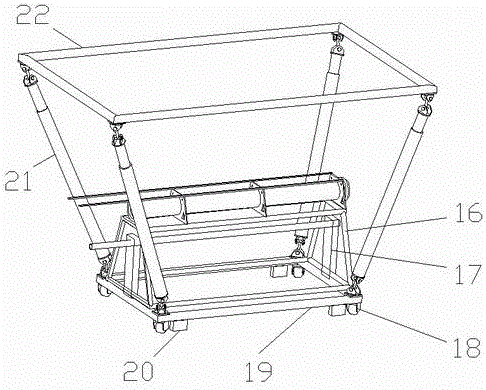

[0015] figure 1 , 4 It shows the structural diagram of the wall-climbing vehicle device for spraying hull panels mounted on the elevated vehicle. This wall-climbing vehicle device for spraying paint on the hull shell mounted on the elevated vehicle includes an elevated vehicle 5, a workbench 4, a recovery cover mechanism 2, a wall-climbing vehicle 3, a feeding mechanism 6, a paint mist recovery hose 7 and a paint supply Hose8. The working basket 23 controls the oil cylinder 28 and the telescopic arm 31 by operating the walking controller 25 and controls the vertical downward movement of the working basket 23. The working basket 23 drives the wall climbing vehicle 3 and the paint mist recovery cover mechanism 2 downward through the supporting frame 22. Move, a plurality of paint nozzles 15 in the paint mist recovery cover 9 complete the painting work in a fan shape at the same time, the operator controls the telescopic arm 31 and the oil cylinder 28 to complete the paint spra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com