Laser processing method for LED wafer

A laser processing method and processing method technology, applied in the direction of laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of low electrical yield rate, achieve the effect of improving yield rate, wide application space, and reducing peak power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below with reference to the accompanying drawings and embodiments.

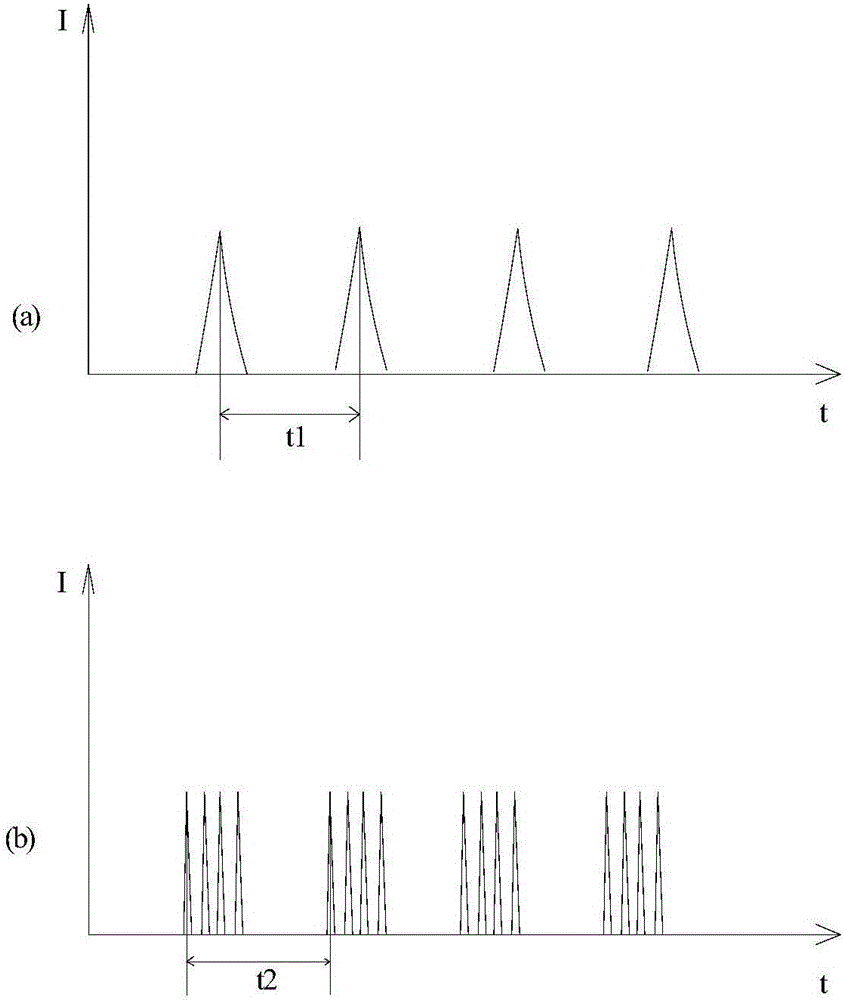

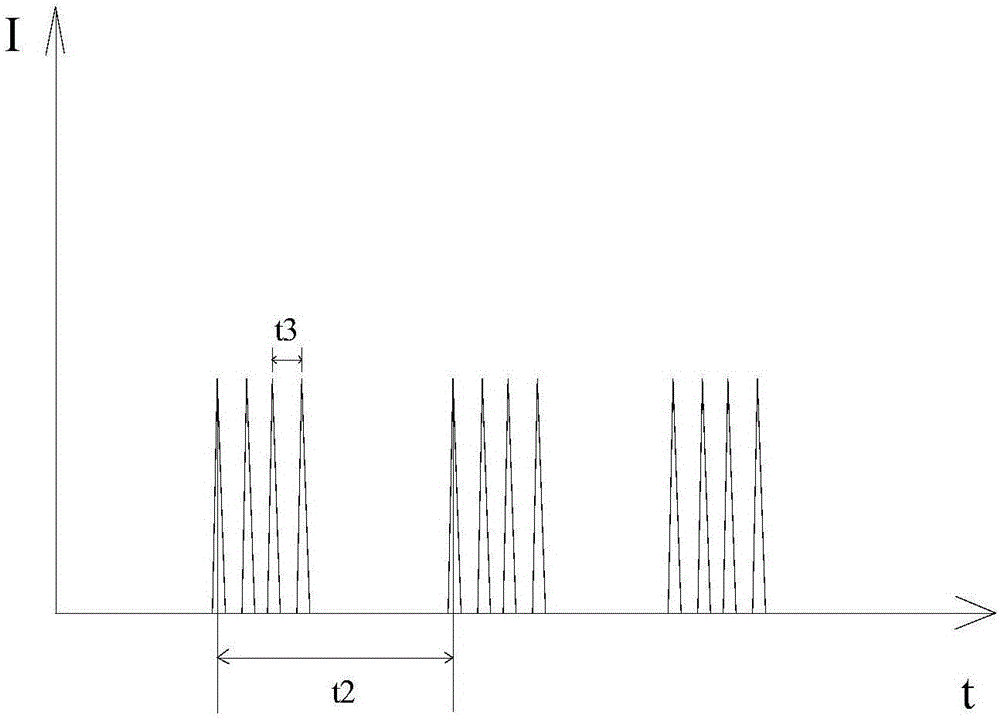

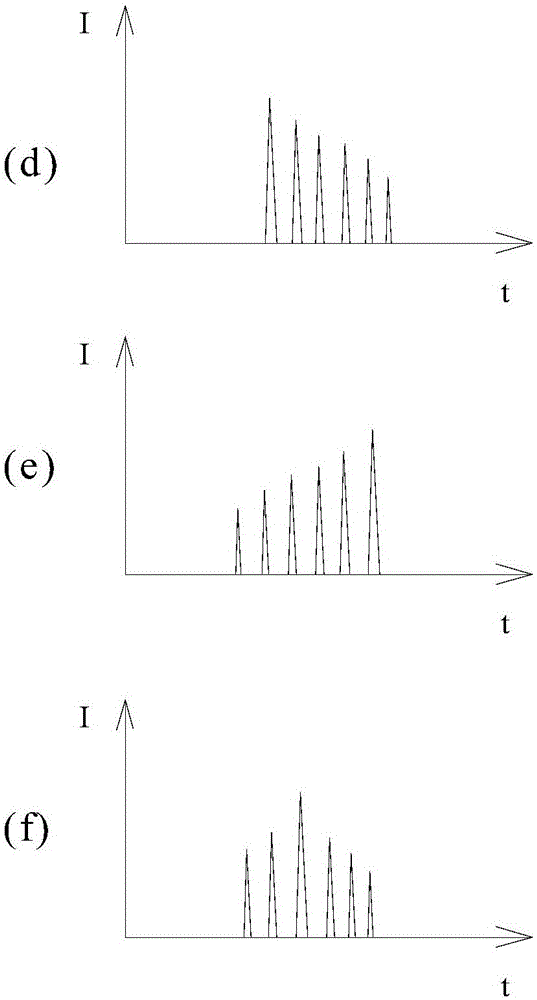

[0026] figure 1 Shown is the comparative schematic diagram of the pulse output of the existing laser and the present invention, such as figure 1 (a) shows the output mode of the existing pulsed laser, and there are single pulse outputs arranged periodically on the time axis t, each pulse has a certain intensity I, and the time interval t1 between adjacent output pulses is a fixed value , and t1=1 / laser output frequency, for example, if the laser output frequency is 50kHz, t1=1 / 50kHz=20us. figure 1 (b) shows that the implementation of the present invention provides a laser processing method, the processing method uses a pulsed laser, and the pulsed laser outputs the laser in a burst mode, or a burst sub-pulse mode, or a burst mode (burst mode) pulse output mode , where the burst sub-pulse mode and the burst mode (burst mode) pulse output mode are coordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com