Device for welding end of coil on stator

A coil end and stator technology, applied in auxiliary devices, welding equipment, welding equipment, etc., can solve the problems of leakage welding and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

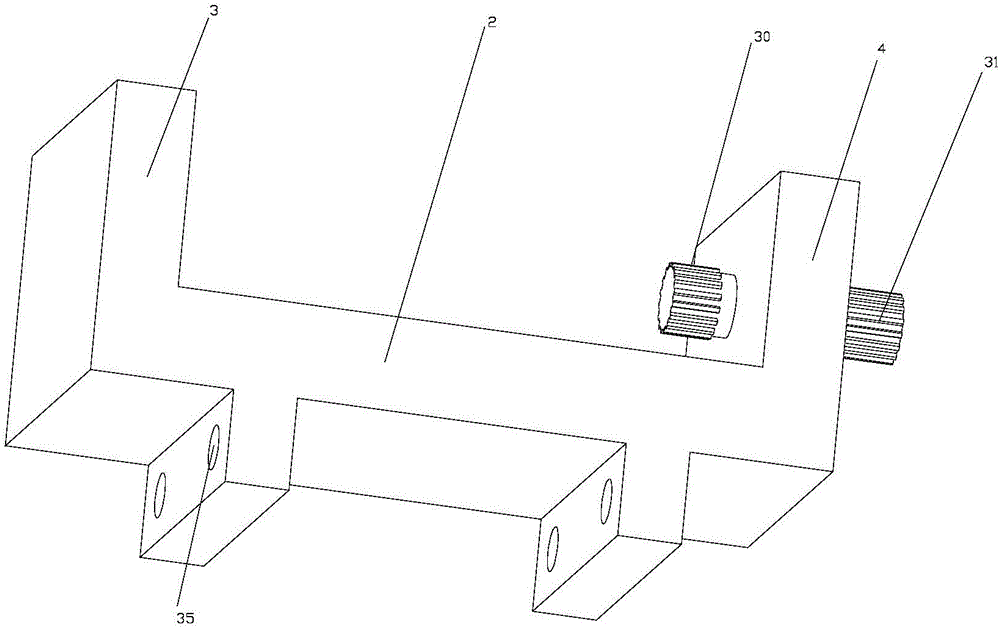

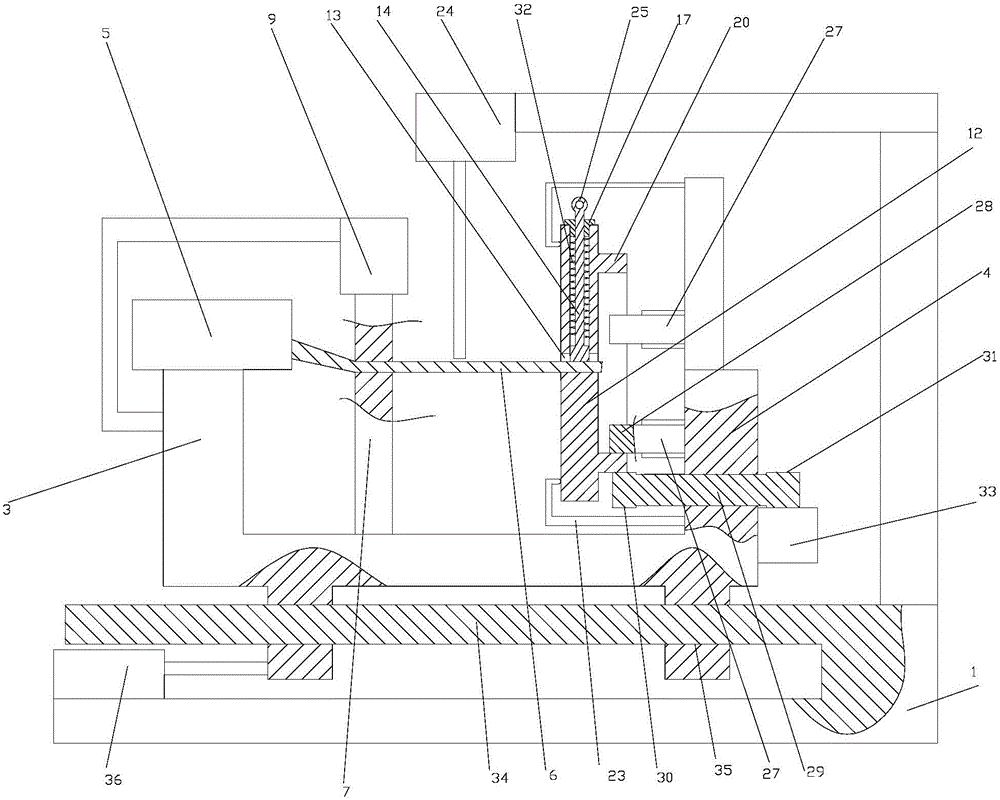

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0024] Working principle of the present invention:

[0025] First, the stator is placed on the platform, and the operator holds the claw on the pull ring to drive the pin to separate from the inner wall of the round hole, and then takes the end of a coil on the stator to pass through the groove on the support rod and the round hole on the turntable in turn. , the operator loosens the pull ring, and the latch slides toward the axis of the turntable under the elastic force of the pressure spring, that is, the claws are snapped onto the inner peripheral wall of the round hole, thereby completing the clamping of the free end of the coil; then, the second cylinder works to clamp the coil in the groove on the support rod;

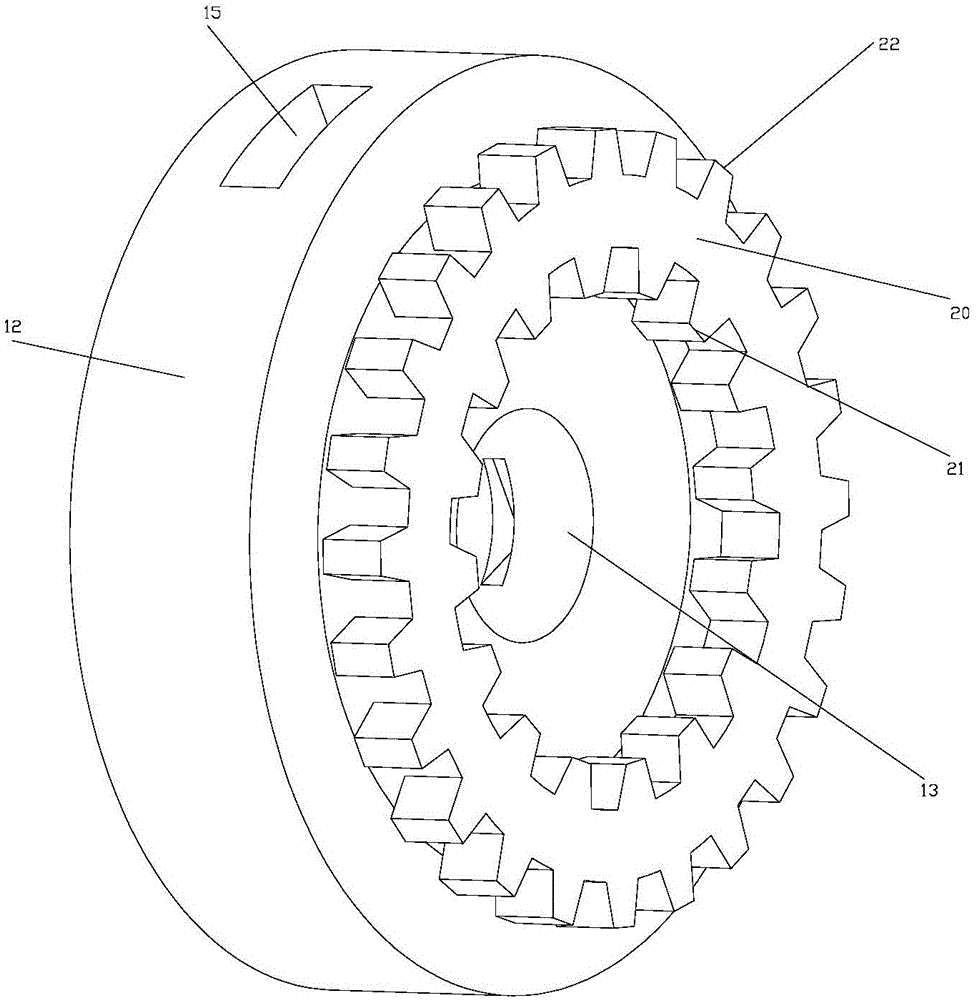

[0026] Then, the motor works to drive the second rotating shaft to rotate, and the second rotating shaft drives the external ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com