Building concrete mixing and stirring device and operation method thereof

A technology for mixing and mixing concrete, which is applied to cement mixing devices, clay preparation devices, unloading devices, etc. It can solve the problems of limited work sites, low work efficiency, and low stability, so as to reduce labor intensity and overcome the use of site restrictions, the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

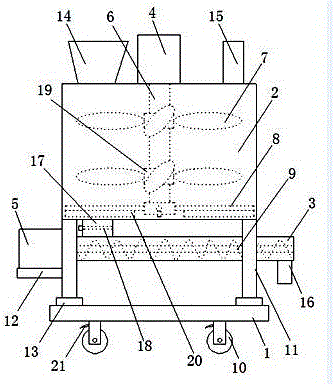

[0022] as attached figure 1 As shown, a concrete mixing and stirring device for construction includes a base plate 1, a mixing chamber 2, a feeding cylinder 3, a motor one 4, a motor two 5, a transmission shaft 6, a stirring blade 7, a material rod 8, and an auger 9 And roller 10, it is characterized in that, described base plate 1 is provided with support 11, and is provided with bearing plate 12 on support 11, and described base plate 1 and support 11 are provided with shock pad 13, described Shock-absorbing pad 13 is set to polymer rubber material, and described mixing chamber 2 is arranged on the support 11, and is provided with feeding bin 14, water inlet pipe 15 on mixing chamber 2, and described feeding tube 3 one end Connect with the mixing chamber 2 through the feeding pipe 17, the other end is provided with the discharging pipe 16, the valve 18 is arranged in the described feeding pipe 17, and the described motor one 4 is arranged on the mixing chamber 2, so The mot...

Embodiment 2

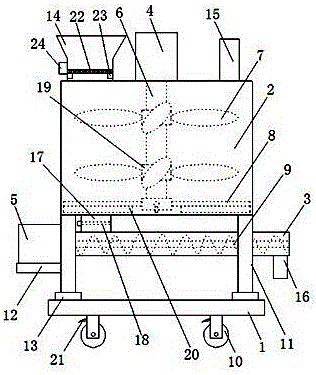

[0030] as attached figure 2As shown, a concrete mixing and stirring device for construction includes a base plate 1, a mixing chamber 2, a feeding cylinder 3, a motor one 4, a motor two 5, a transmission shaft 6, a stirring blade 7, a material rod 8, and an auger 9 , roller 10 and sieve plate 22, it is characterized in that, described base plate 1 is provided with support 11, and is provided with bearing plate 12 on support 11, and described base plate 1 and support 11 are provided with shock pad 13 , the shock-absorbing pad 13 is provided with a shock-absorbing spring, the mixing chamber 2 is arranged on the bracket 11, and a feeding bin 14 and a water inlet pipe 15 are arranged on the mixing chamber 2, and the feeding A vibrating motor 23 is arranged in the bin 14, and a miscellaneous outlet 24 is arranged on the outer wall of the feeding bin 14. One end of the transfer cylinder 3 is connected with the mixing chamber 2 through a feeding tube 17, and an outlet port 24 is arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com