Container used for railway and highway transportation

A road transportation and container technology, applied in the field of containers, can solve the problems of inability to realize resource recycling, failure to meet low-carbon environmental protection requirements, and high quality of small boxes, and achieve low-carbon environmental protection requirements, light weight, and high installation efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

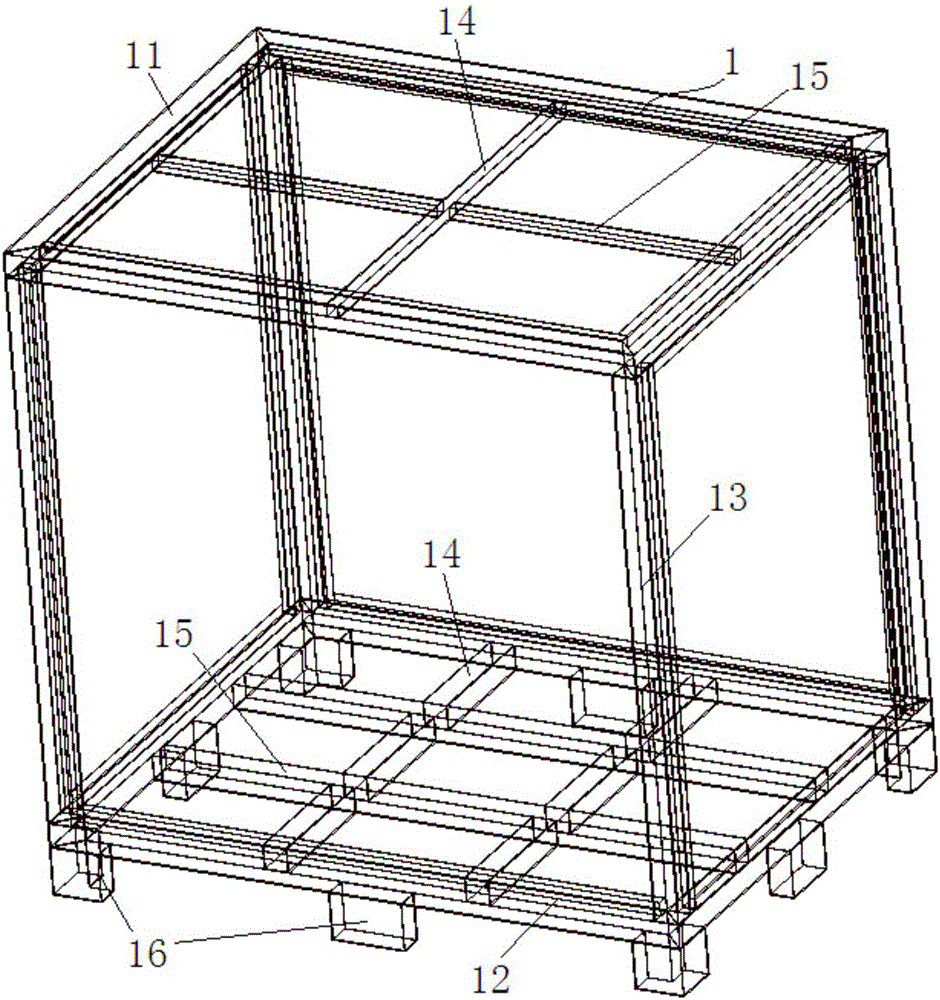

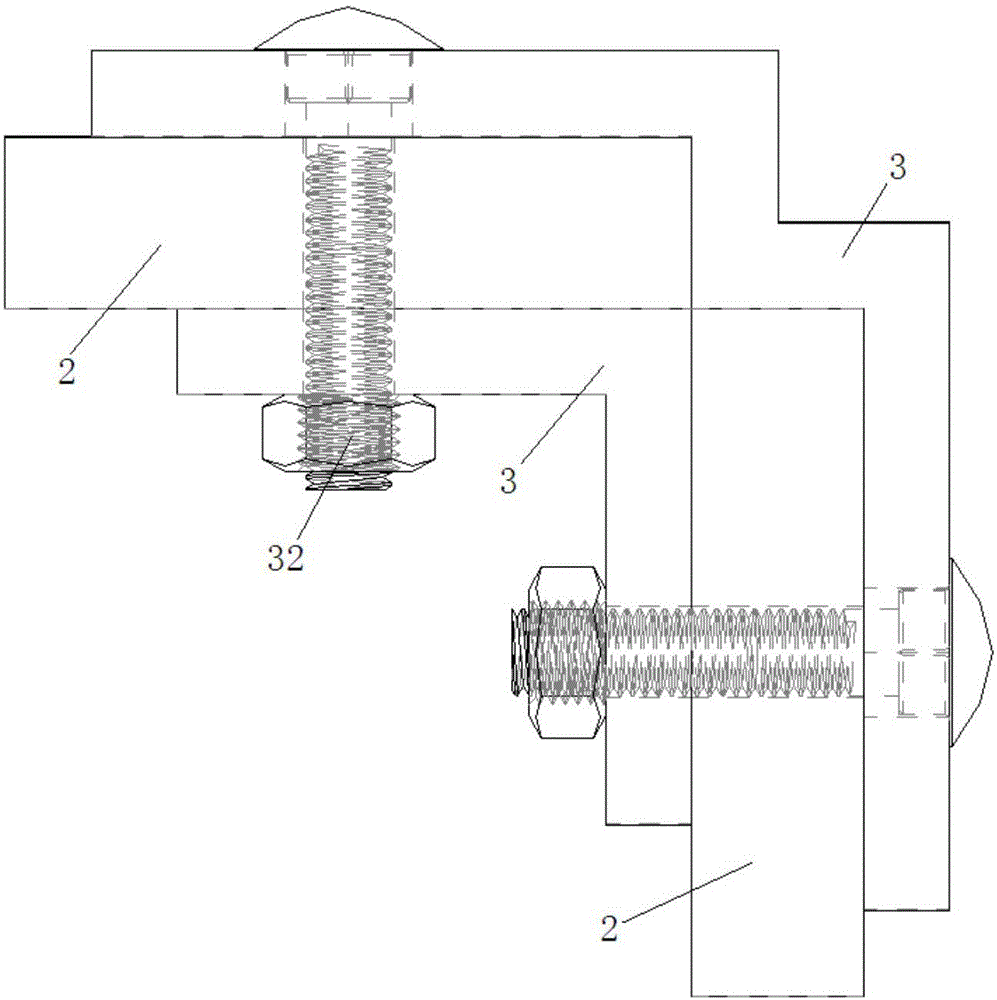

[0020] Such as figure 1 Shown, the present invention proposes a kind of container that is used for railway and road transportation, and it comprises box body frame 1 and is arranged on box body frame 1 top, bottom and the honeycomb panel 2 (as figure 2 shown). Wherein, the box frame 1 includes a top frame 11 , a bottom frame 12 and a corner column 13 connecting the top frame 11 and the bottom frame 12 .

[0021] In the above embodiments, the box frame 1 is rectangular.

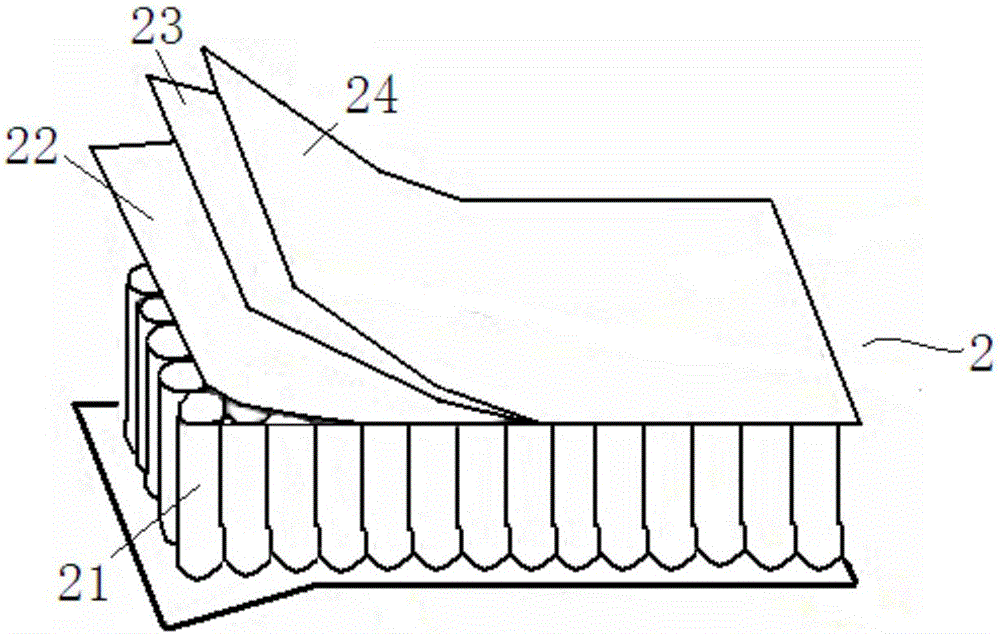

[0022] In the above embodiments, the honeycomb panel 2 is a thermoplastic honeycomb panel. Such as figure 2 As shown, the honeycomb panel includes a honeycomb middle layer 21, and connecting panels 22 are respectively fastened on both ends of the honeycomb middle layer 21 to form a sandwich structure, which can increase rigidity, strength and shock absorption performance. The c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com