Flexible material conveying and correction device based on the principle of air suspension

A technology of flexible materials and correction devices, which is applied in the directions of transportation and packaging, thin material handling, and separation of objects, etc., can solve the problems of not being able to be gripped or grasped by manipulator claws, easily deformed, and unable to be grasped by adsorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

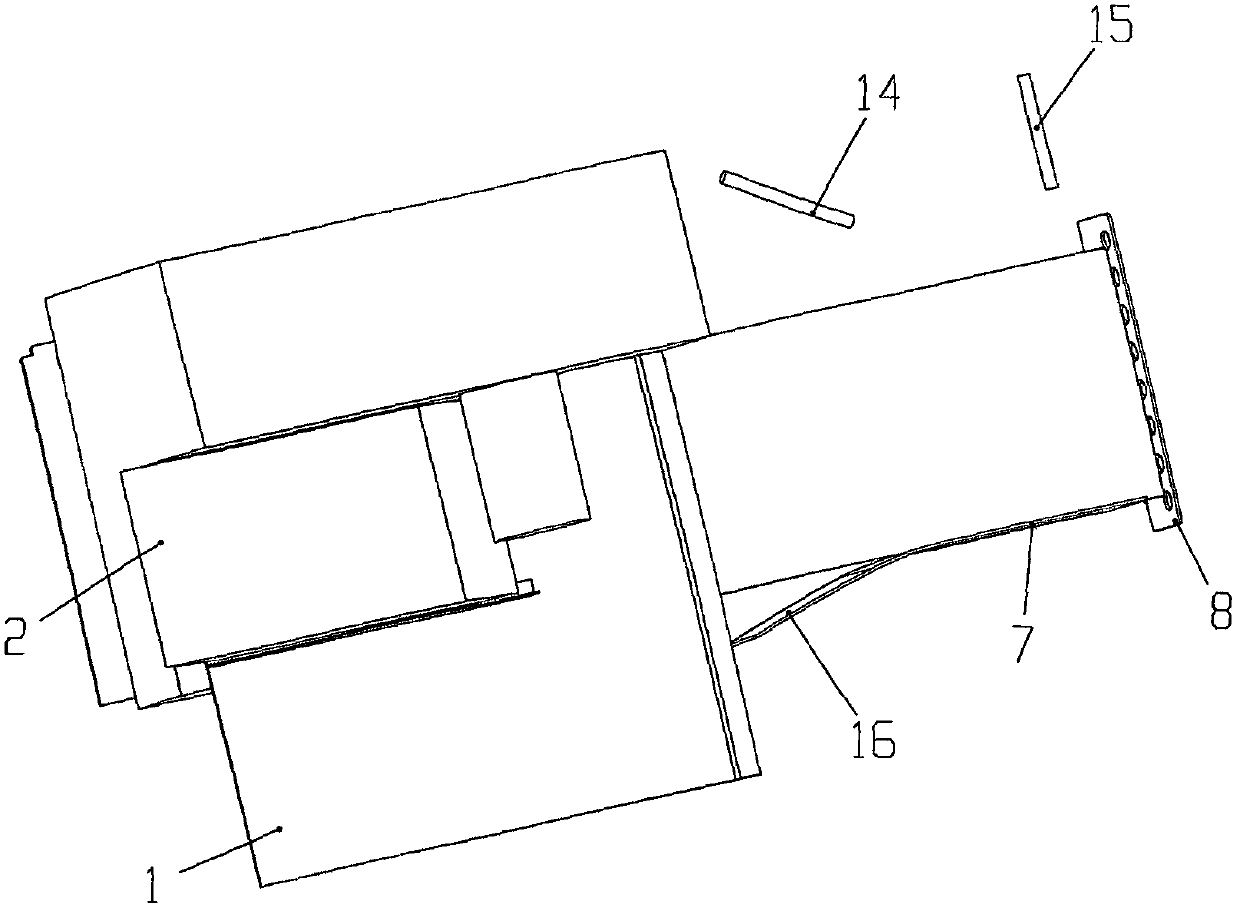

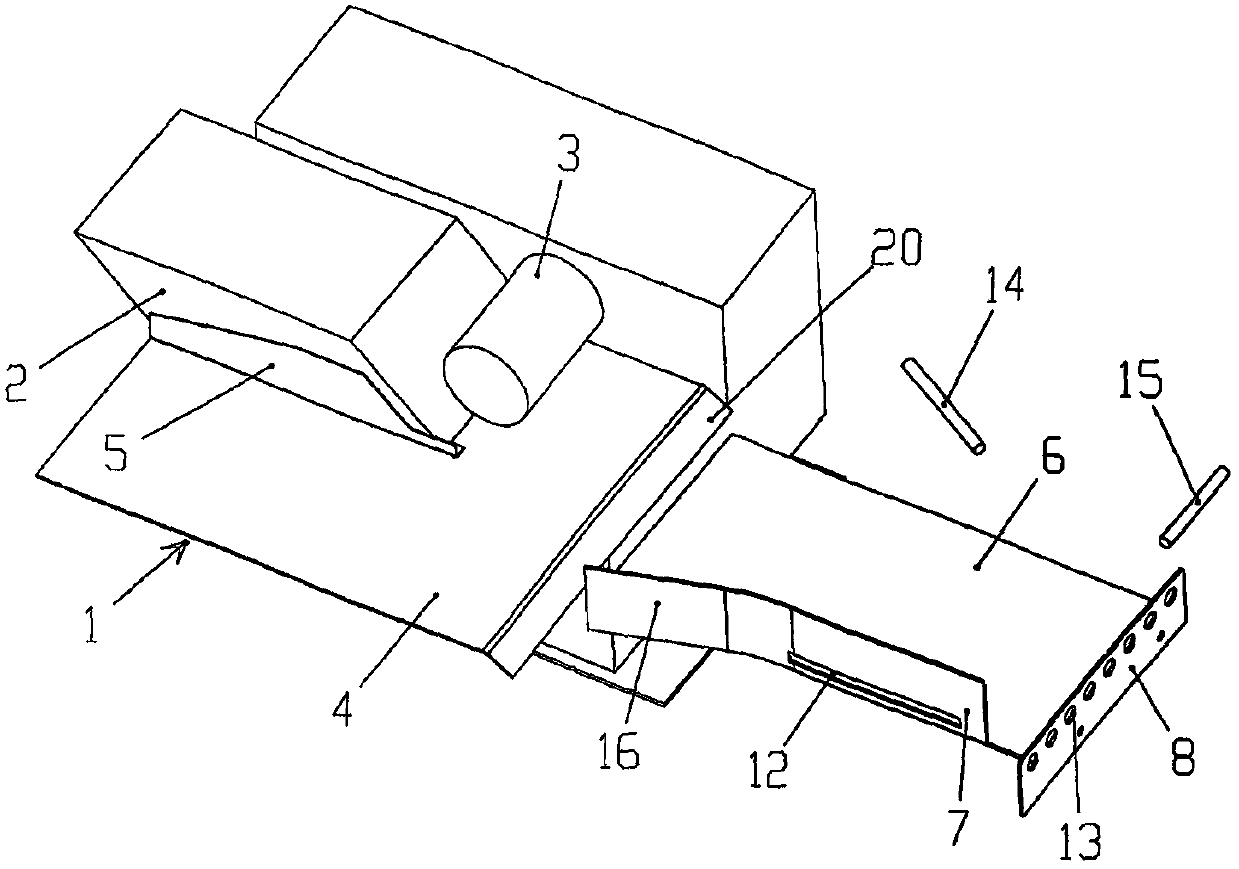

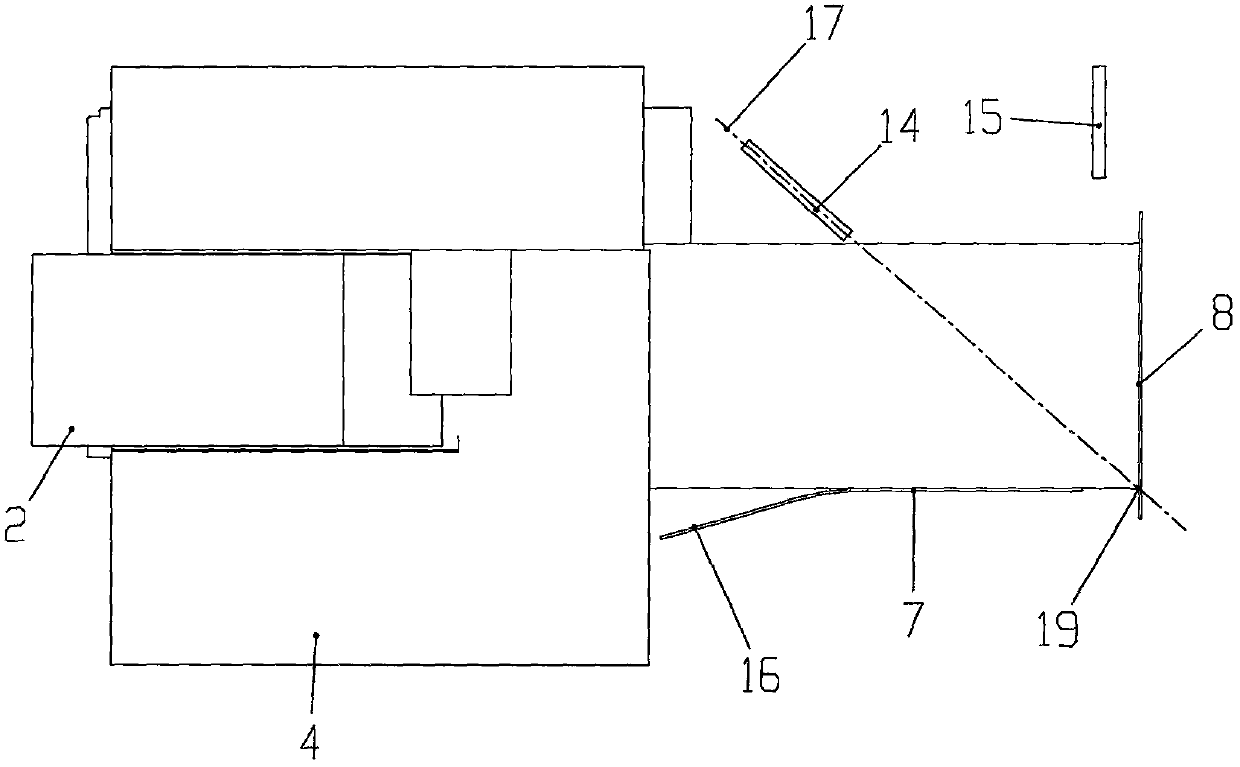

[0034] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements. As mentioned above, the present invention provides a flexible material conveying and correcting device based on the principle of air suspension, which is used for conveying flexible materials such as paper, from which a stack of paper is conveyed and a paper is conveyed, and the paper is transported by air. Transport to the predetermined position, and use the airflow to correct the paper. After the paper is in place on the workbench, make the paper reach the predetermined position accurately and adjust the posture; the paper is transported by using the airflow to assist the paper At the same time, the airflow is used to correct the paper, and the invention has the characteristics of simple implementation and high correction efficiency.

[0035] figure 1 , 2 , 3, 4 are structural schematic diagrams of the flexible material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com