Spongy soil and preparation method thereof

A technology of sponge soil and organic matrix, applied in the field of landscaping, can solve the problems of lack of urban greening planting soil, poor soil structure of planting soil, etc., and achieve the effects of low cost, promoting development, and good permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

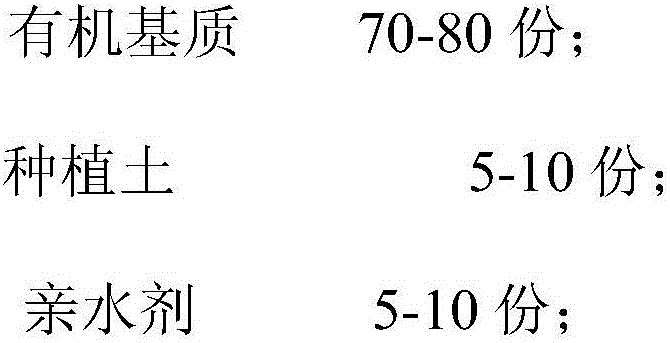

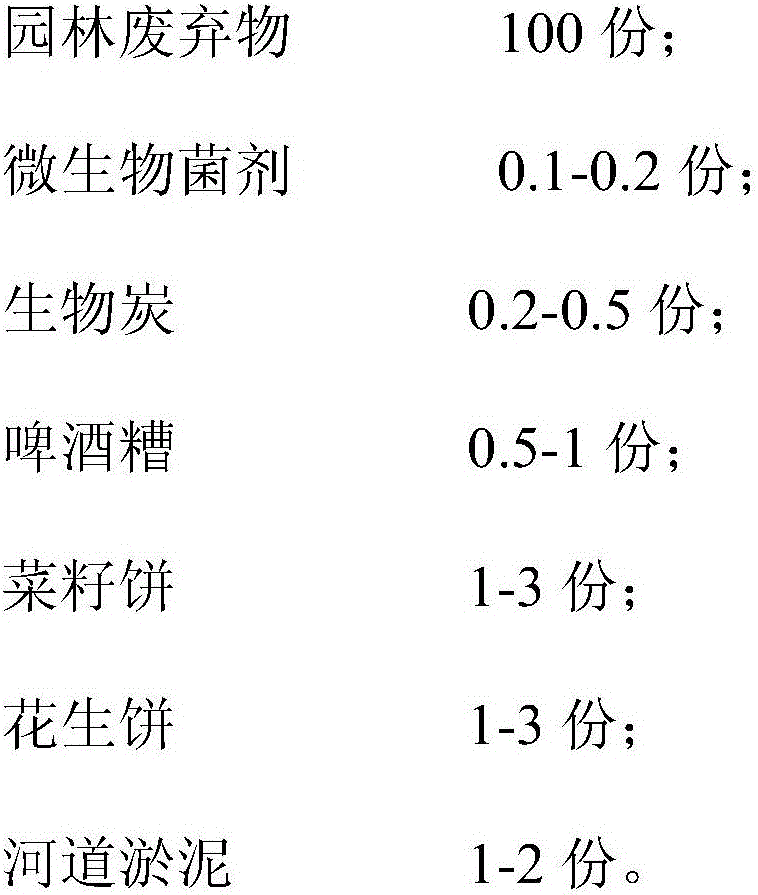

Method used

Image

Examples

Embodiment 1

[0037] A preparation method of sponge soil, comprising the steps of:

[0038] Step 1: put 1000 kg of garden waste collected into a pulverizer to pulverize to obtain garden waste particles with a particle size of 3-10 mm;

[0039] Step 2: Mix the garden waste granules obtained in Step 1 with 1kg of microbial agent, 2kg of biochar, 5kg of brewer's grains, 10kg of rapeseed cake, 10kg of peanut cake, and 10kg of river silt, and adjust the water content to 55%-60% After obtaining the mixture;

[0040] Step 3: Put the mixture obtained in Step 2 into a microbial fermentation tank for aerobic fermentation;

[0041] Step 4: Measure the temperature and moisture of the pile. When the temperature exceeds 55°C or the water content exceeds 30%, turn on the dump truck for dumping. Each time the dump truck walks in the forward and reverse directions, one fermentation is completed in 5-7 days Then the material after the primary fermentation is moved out of the microbial fermentation tank and...

Embodiment 2

[0045] A preparation method of sponge soil, comprising the steps of:

[0046] Step 1: put 1000 kg of garden waste collected into a pulverizer to pulverize to obtain garden waste particles with a particle size of 3-10 mm;

[0047] Step 2: Mix the garden waste granules obtained in Step 1 with 1.5kg of microbial agent, 4kg of biochar, 8kg of brewer's grains, 15kg of rapeseed cake, 15kg of peanut cake, and 15kg of river silt, and adjust the water content to 55%-60 The mixture is obtained after %;

[0048] Step 3: Put the mixture obtained in Step 2 into a microbial fermentation tank for aerobic fermentation;

[0049] Step 4: Measure the temperature and moisture of the pile. When the temperature exceeds 55°C or the water content exceeds 30%, turn on the dump truck for dumping. Each time the dump truck walks in the forward and reverse directions, one fermentation is completed in 5-7 days Then the material after the primary fermentation is moved out of the microbial fermentation tan...

Embodiment 3

[0053] A preparation method of sponge soil, comprising the steps of:

[0054] Step 1: put 1000 kg of garden waste collected into a pulverizer to pulverize to obtain garden waste particles with a particle size of 3-10 mm;

[0055] Step 2: Mix the garden waste granules obtained in Step 1 with 2kg of microbial agent, 5kg of biochar, 10kg of brewer's grains, 20kg of rapeseed cake, 20kg of peanut cake, and 20kg of river silt, and adjust the water content to 55%-60% After obtaining the mixture;

[0056] Step 3: Put the mixture obtained in Step 2 into a microbial fermentation tank for aerobic fermentation;

[0057] Step 4: Measure the temperature and moisture of the pile. When the temperature exceeds 55°C or the water content exceeds 30%, turn on the dump truck for dumping. Each time the dump truck walks in the forward and reverse directions, one fermentation is completed in 5-7 days Then the material after the primary fermentation is moved out of the microbial fermentation tank an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com