Transverse-grain-resistant, wall-shrinkage-resistant and low-warping polypropylene composite

A technology of anti-tiger-skin and composite materials, which is applied in the field of anti-tiger-skin, anti-shrinkage, and low-warp polypropylene composite materials. It can solve the problem of affecting the appearance of products, limiting the use of polypropylene materials, and slow cooling and solidification. And other problems, to improve product quality, good compatibility, increase the effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

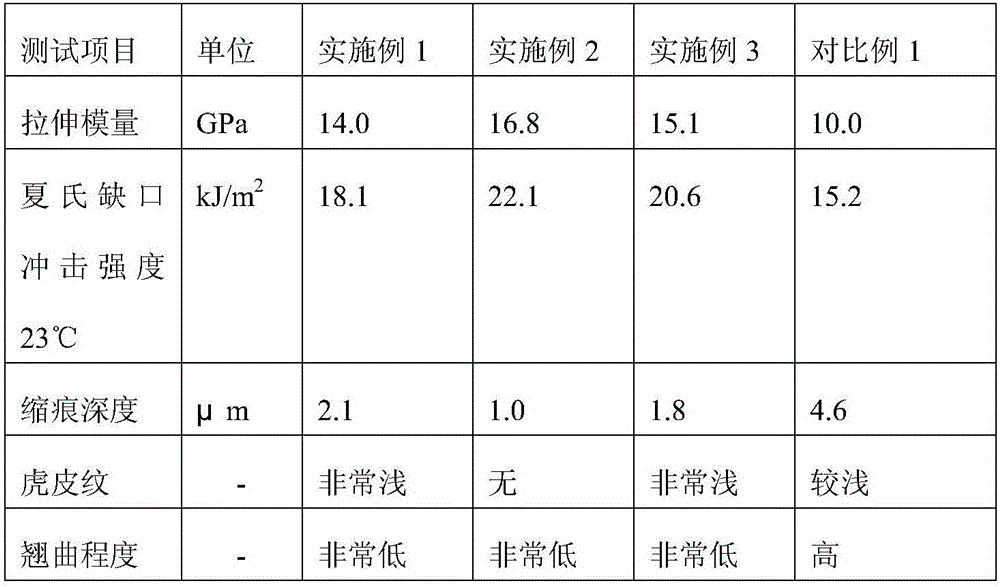

Examples

Embodiment 1

[0018] Weigh 100 parts of polypropylene, 10 parts of K resin, 15 parts of porous silica filler, 1 part of compatibilizer, and 0.5 parts of auxiliary agent in parts by weight. The polypropylene is according to ASTMD1238-99, the condition is 230 ° C / 2.16 kg , The measured melt flow rate is 10-30g / 10min.

[0019] In the present invention, K resin refers to styrene-butadiene transparent impact-resistant resin, and the porous silica filler is porous silica microspheres.

[0020] Dry mix the above raw materials in a high-speed mixer for 10 minutes, then melt and extrude them in a twin-screw extruder, and granulate to obtain the polypropylene composite material of the present invention. The process control conditions are: 180-190 ℃, 200~210℃ in the second zone, 200~210℃ in the third zone, 210~215℃ in the fourth zone, 210~215℃ in the fifth zone, 210~215℃ in the sixth zone, 215~225℃ in the seventh zone, 215~225℃ in the eighth zone , 215-225°C in the ninth zone, 215-225°C in the tent...

Embodiment 2

[0023] (1) First prepare porous silica microspheres with hydrocarbon groups on the surface: place the porous polymer microspheres in ethanol for ultrasonication, then add ammonia water, methyl orthosilicate or ethyl orthosilicate in ethanol solution, After stirring and reacting for 20 hours, wash, dry, and finally place it in a muffle furnace for calcination to obtain unmodified silica microspheres, and then use chemical methods to graft hydrocarbon groups on the surface of unmodified silica microspheres to obtain surface-modified hydrocarbon groups Porous silica microspheres with a particle size of 10 μm and a pore size of

[0024] (2) Weigh 100 parts of polypropylene, 18 parts of K resin, 20 parts of porous silica filler, 8 parts of compatibilizer, and 0.1 part of auxiliary agent in parts by weight. The polypropylene is based on ASTMD1238-99 and the condition is 230 ° C / 2.16kg, the measured melt flow rate is 10-30g / 10min.

[0025] (3) The above raw materials were melt-bl...

Embodiment 3

[0027] (1) First prepare porous silica microspheres with hydrocarbon groups on the surface: place the porous polymer microspheres in ethanol for ultrasonication, then add ammonia water, methyl orthosilicate or ethyl orthosilicate in ethanol solution, After stirring and reacting for 20 hours, wash, dry, and finally place it in a muffle furnace for calcination to obtain unmodified silica microspheres, and then use chemical methods to graft hydrocarbon groups on the surface of unmodified silica microspheres to obtain surface-modified hydrocarbon groups Porous silica microspheres; the particle size is 5 μm, and the pore size

[0028] (2) Weigh 100 parts of polypropylene, 10 parts of K resin, 10 parts of porous silica filler, 5 parts of compatibilizer, and 0.6 parts of auxiliary agent according to parts by weight. / 2.16kg, the measured melt flow rate is 10-30g / 10min.

[0029] (3) The above raw materials were melt-blended to prepare polypropylene composite material, and the prepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com