Blade type concrete spraying machine

A concrete jetting machine and vane-type technology, which is applied in earthwork drilling, wellbore lining, tunnel lining, etc., can solve the problems of difficult transportation and storage of liquid accelerator, low machine size and performance, and easy wear and tear of spraying equipment, and achieve high performance Efficient and reliable, compact and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

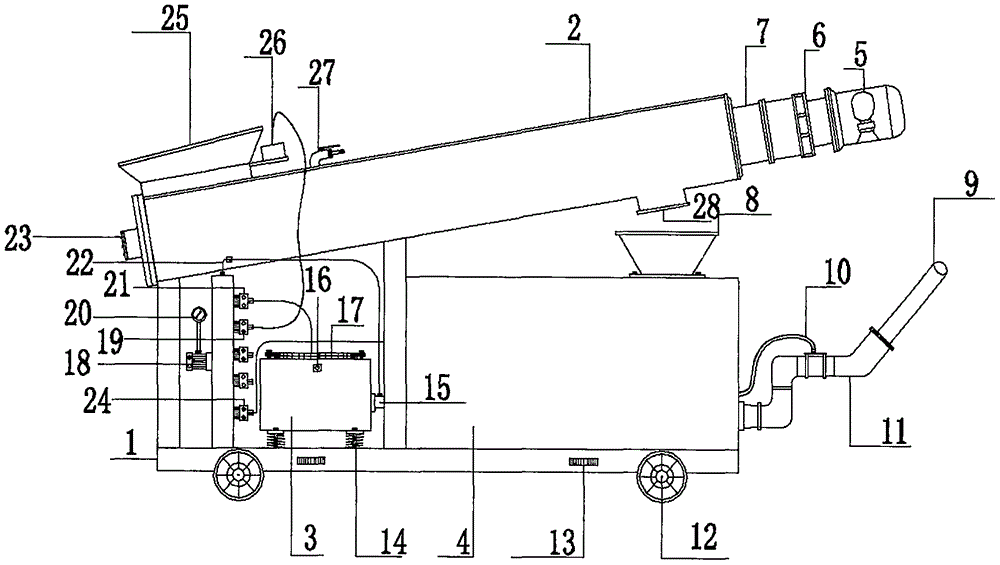

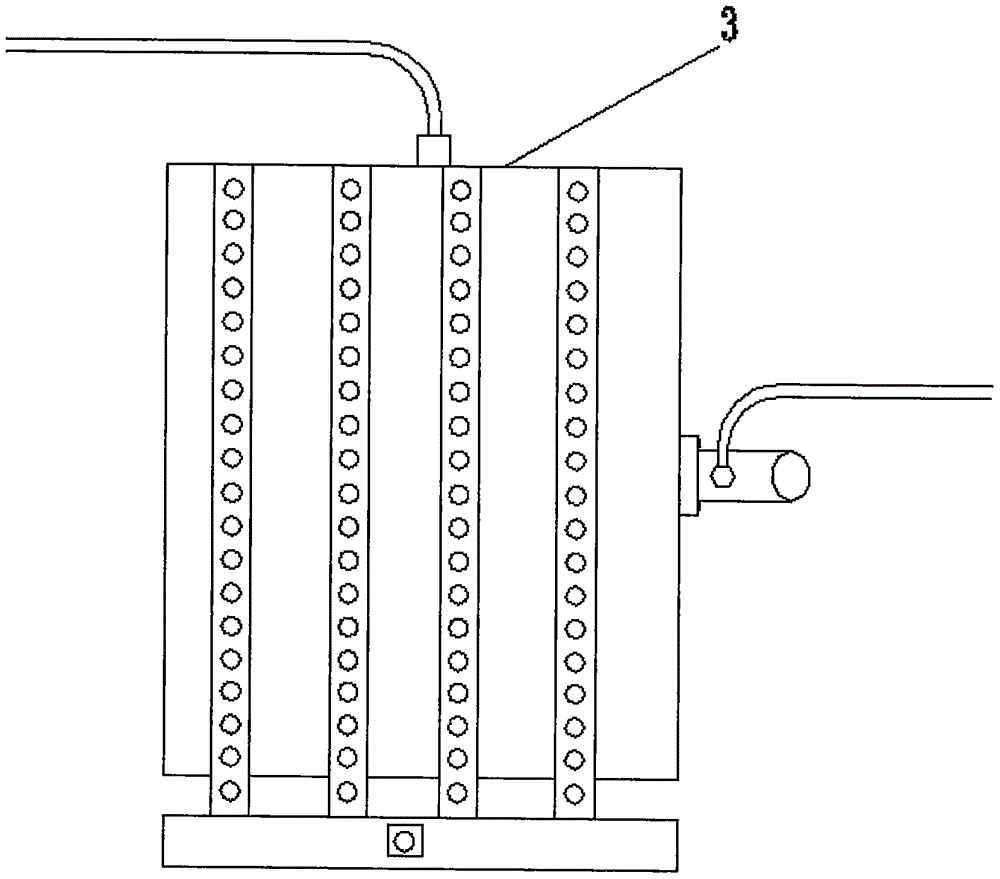

[0013] figure 1 A structural schematic diagram of the blade type concrete sprayer of the present invention is provided, which is composed of a frame 1, a screw conveyor 2, an accelerator pump 3, a shotcrete machine 4, wheels 12 and an air compressor, and the wheels 12 are installed on the machine Under the frame 1, the air compressor, quick-setting agent pump 3 and spraying machine 4 are successively installed on the platform of the frame 1, and the screw conveyor 2 is fixed on the frame 1 by two pillars, and it is characterized in that 2: the left end of the screw conveyor 2 is equipped with a screw bearing assembly 23; one end of the screw conveyor shaft 7 is connected with the screw bearing assembly 23, and the other end is connected with the power output shaft of the flameproof motor 5 through the reducer 6; The upper left end of the screw conveyor 2 is equipped with a feed hopper 25 and a screw conveyor water supply switch assembly 27 in turn, and the lower right end is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com