A construction method for grouting and water-stopping of bare rock in underground caverns

A technology for underground caverns and bare rock, which is applied in underground caverns, earthwork drilling, wellbore lining, etc. It can solve problems such as increasing safety risks in underground cavern construction, affecting the quality of bolting and spraying support, and restricting the construction progress of caverns. , to achieve the effect of increasing bonding, reducing the use of materials, and reducing deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A construction method for water-stop grouting in underground caverns, comprising the following steps:

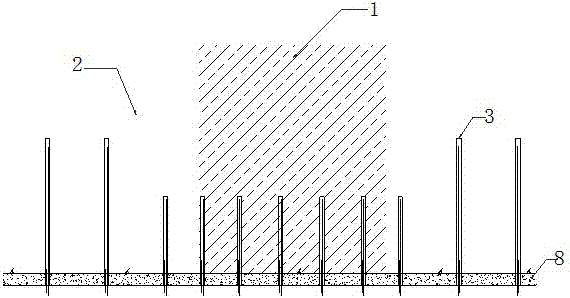

[0035] Step (1), determination of the grouting range in the seepage area of the underground cavern: After excavation of the surrounding rock of the underground cavern, check the seepage area, and take the area exceeding 6.0m around the seepage area as the grouting range;

[0036] Step (2), determination of the grouting hole parameters in the grouting range of the underground cavern: Arrange the grouting holes in the grouting range, the grouting hole diameter is 40mm, the grouting hole spacing is 0.4-0.6m, the grouting hole depth is 6.0mm, the density of the grouting holes in the seepage area Greater than the density of the grouting holes surrounding the water seepage area;

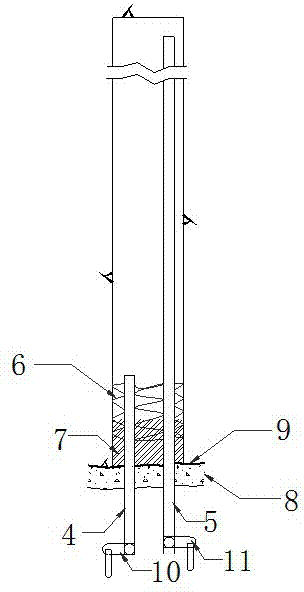

[0037] Step (3), pre-embed seepage drainage pipe and grout return pipe: the length of the drainage pipe is 40cm, and the drainage pipe gate valve is installed on the drainage pipe. The gate val...

Embodiment 2

[0046] A construction method for water-stop grouting in underground caverns, comprising the following steps:

[0047] Step (1), determination of the grouting range in the seepage area of the underground cavern: After excavation of the surrounding rock of the underground cavern, check the seepage area, and use the area exceeding 9.0m around the seepage area as the grouting range;

[0048] Step (2), determination of grouting hole parameters in the grouting range of the underground cavern: Arrange grouting holes within the grouting range, the grouting hole diameter is 90mm, the grouting hole spacing is 0.8-1.0m, the grouting hole depth is 6.0m~12.0m, grouting in the seepage area The density of the holes is greater than the density of the grouting holes around the area beyond the water seepage;

[0049] Step (3), pre-embed seepage drainage pipe and grout return pipe: the length of the drainage pipe is 60cm, and the drainage pipe gate valve is installed on the drainage pipe. The...

Embodiment 3

[0060] A construction method for water-stop grouting in underground caverns, comprising the following steps:

[0061] Step (1), the grouting range of the seepage area of the underground cavern is determined: after the excavation of the surrounding rock of the underground cavern, check the seepage area, and take the area exceeding 7.0m around the seepage area as the grouting range;

[0062] Step (2), determination of the grouting hole parameters in the grouting range of the underground cavern: Arrange the grouting holes within the grouting range, the diameter of the grouting holes is 70mm, the distance between the grouting holes is 0.6~0.8m, the depth of the grouting holes is 6.0m~12.0m, and the grouting in the seepage area The density of the holes is greater than the density of the grouting holes around the area beyond the water seepage;

[0063] Step (3), pre-embed seepage drainage pipe and grout return pipe: the length of the drainage pipe is 50cm, and the drainage pipe ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com