Large-span support method and device of medium-caliber self-bearing straight steel pipe bridge

A supporting device and large-span technology, applied in the direction of pipe supports, pipes/pipe joints/fittings, mechanical equipment, etc., can solve problems that have not been reported, and achieve the effect of saving the number of pipes, smooth appearance, and no wrinkles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 2

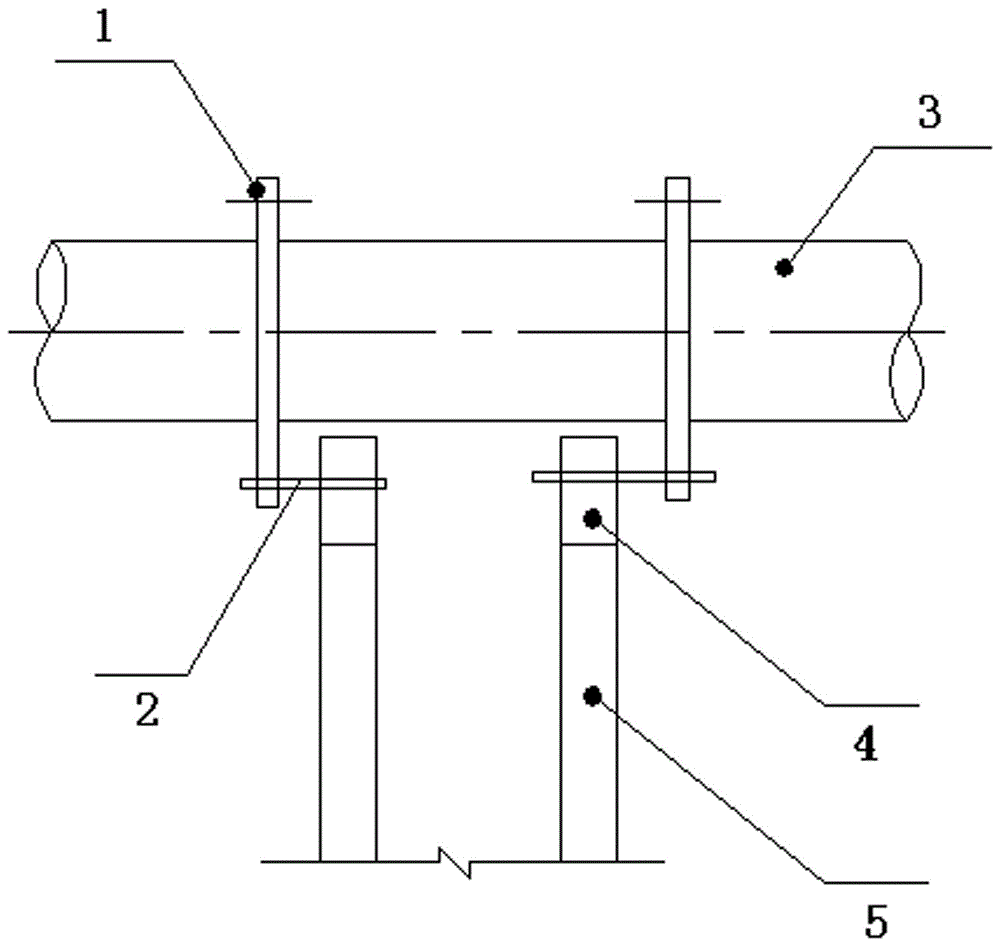

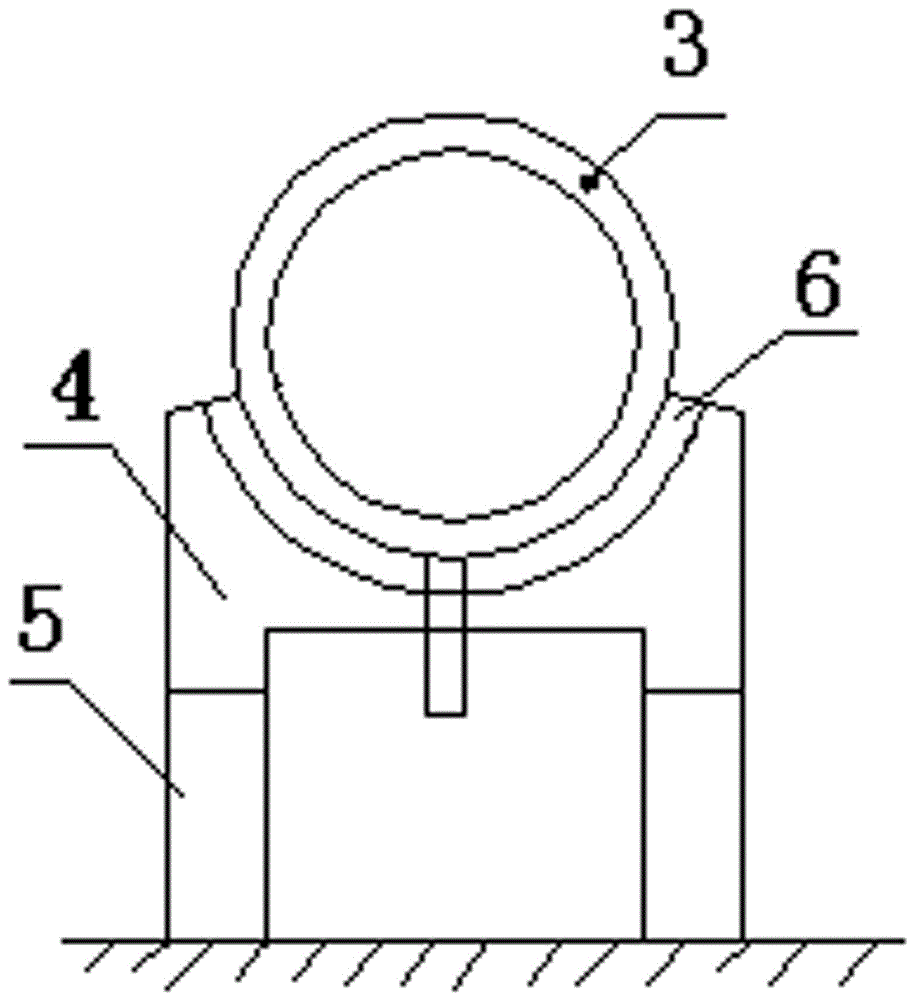

[0056] Guangxi Longlin Autonomous County Sewage Treatment Plant DN700 cross-plant water conservancy water pipeline, the span is more than the national standard Atlas 05S506-1. The inventor adopts a large-span support device for a flat sewage pipe, which is to install a large-span sewage pipe on Figure 1-2 The flexible supporting seat is composed of cement concrete pipe pier 4, pipe bracket and fixing frame 2. The cement concrete pipe pier 4 is installed on the foundation or buttress 5. The end face of the cement concrete pipe pier is The arc shape corresponds to the diameter of the steel pipe; the pipe bracket is installed in the end surface of the cement concrete pipe pier 4; the rubber pad 6 is placed on the pipe bracket, the sewage pipe 3 is placed on the rubber pad 6, and the sewage pipe is fixed to the cement with a fixing frame 2 On the concrete pipe pier 4; the end surface of the cement concrete pipe pier 4 is provided with holes for fixing the sewage pipe on the cement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com