Liquid hydrogen supercooling degree acquiring device

An acquisition device and supercooling degree technology, which is applied in the field of liquid hydrogen supercooling degree acquisition device, can solve the problems of liquid solidification, low liquid supercooling degree, low-temperature propellant leakage, etc., and achieve the reduction of supercooling time and the weakening of boiling degree , the evenly distributed effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

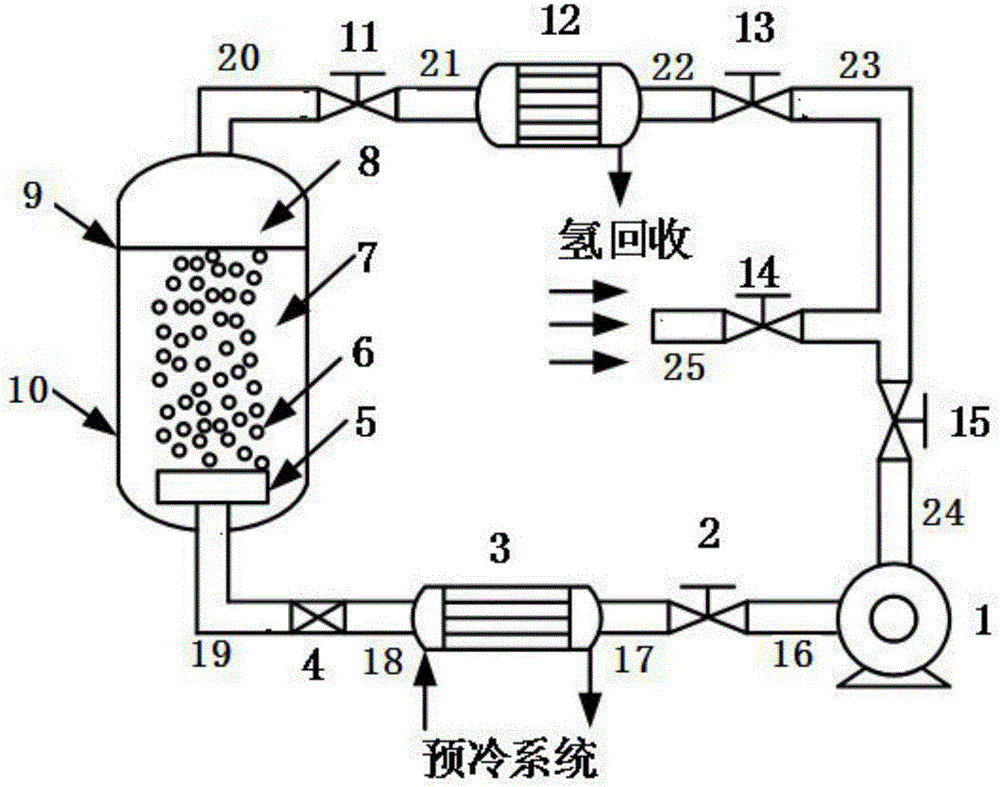

[0018] The present invention will be further described below in conjunction with accompanying drawing.

[0019] refer to figure 1 , a liquid hydrogen subcooling acquisition device, including a compressor 1, the outlet of the compressor 1 is connected to the inlet of the first valve 2 through the first pipeline 16, and the outlet of the first valve 2 is connected to the pre- The inlet of the precooling heat exchanger 3 in the cold system is connected, the outlet of the precooling heat exchanger 3 is connected with the inlet of the throttling device 4 through the third pipeline 18, and the outlet of the throttling device 4 is connected through the fourth pipeline 19 and the bubbling The inlet of the device 5 is connected, the bubbling device 5 is located in the liquid hydrogen 7 of the subcooler 10, and the bubbling device 5 forms helium bubbles 6 in the liquid hydrogen 7;

[0020] The outlet of the gas hydrogen 8 of the subcooler 10 is connected with the inlet of the second va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com