Probe-type film thickness measuring machine automatic wiped film measuring device and using method thereof

A measuring machine and probe-type technology, which is applied in the direction of electromagnetic measuring devices, electric/magnetic thickness measurement, etc., can solve the problems of manual scraping film accuracy cannot be guaranteed, the risk of fragmentation, and the time to increase the measuring range of the machine, so as to avoid damage Measured objects, improved accuracy and operability, and reduced measurement time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

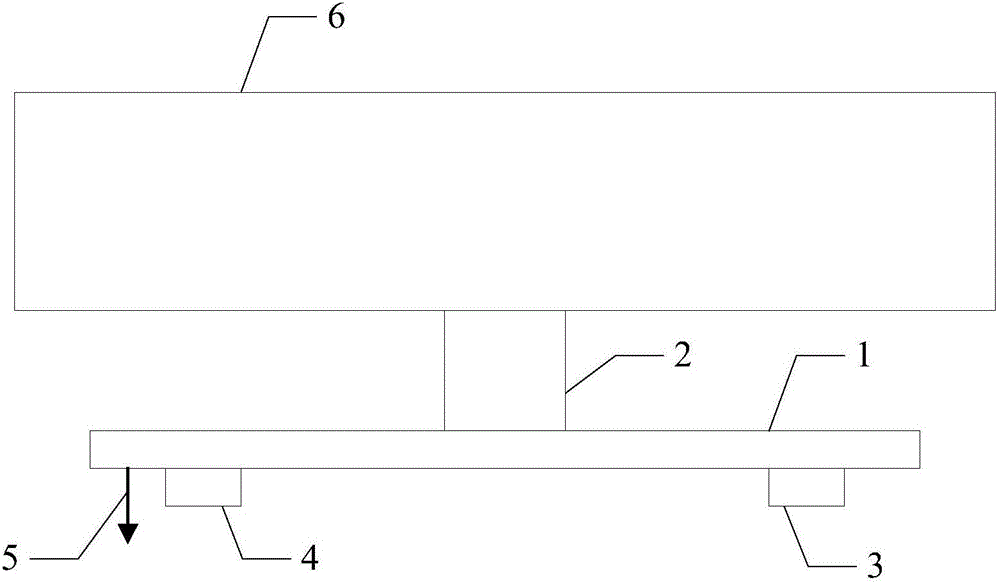

[0032] Specific implementation mode one: combine figure 2 and image 3 Describe this embodiment, a probe-type film thickness measuring machine automatic scraping film measuring device described in this embodiment, including a measuring chassis 6, a measuring head shaft 2, a measuring disc 1, a search CCD 3, a measuring CCD4 and measuring needle 5;

[0033] One end of the measuring head shaft 2 is arranged at the bottom of the measuring machine case 6, and the other end of the measuring head shaft 2 is fixed on the upper surface of the measuring disc 1; the measuring head shaft 2 is used to drive the measuring disc 1 to rotate;

[0034] The search CCD3, the measurement CCD4 and the measurement needle 5 are all arranged on the lower surface of the measurement disk 1; the search CCD3 is used to determine the measurement point of the measurement object; the measurement CCD4 is used to provide visual field observation during measurement, so that Draw the height change curve of t...

specific Embodiment approach 2

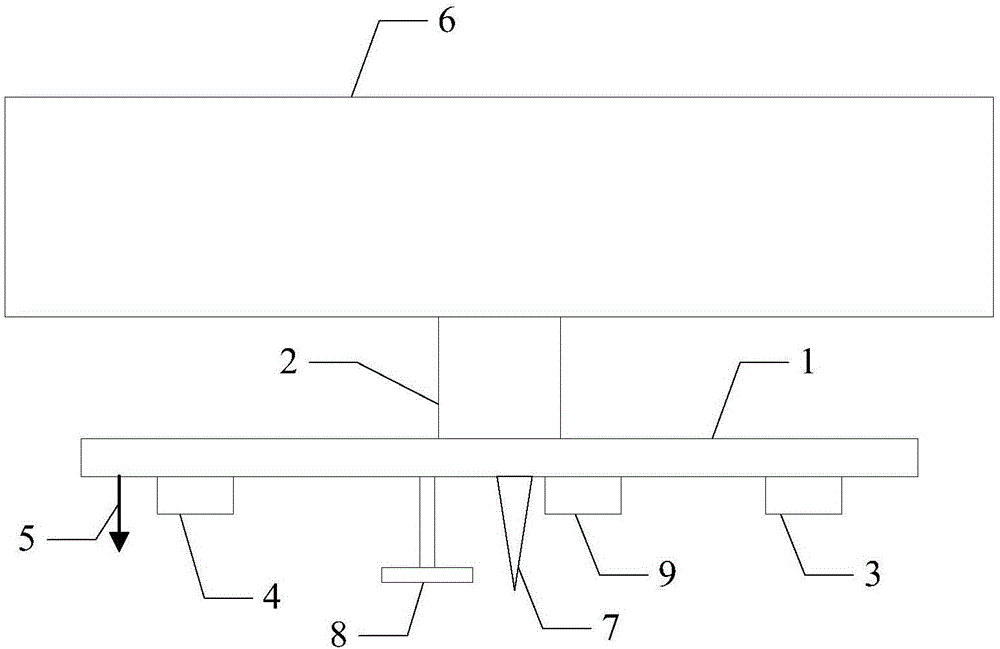

[0041] Specific embodiment 2: A probe-type film thickness measuring machine automatic scraping film measuring device described in this embodiment includes a measuring chassis 6, a measuring head shaft 2, a measuring disc 1, a search CCD 3, a measuring CCD4 and measuring needle 5;

[0042] One end of the measuring head shaft 2 is arranged at the bottom of the measuring machine case 6, and the other end of the measuring head shaft 2 is fixed on the upper surface of the measuring disc 1; the measuring head shaft 2 is used to drive the measuring disc 1 to rotate;

[0043] The search CCD3, the measurement CCD4 and the measurement needle 5 are all arranged on the lower surface of the measurement disk 1; the search CCD3 is used to determine the measurement point of the measurement object; the measurement CCD4 is used to provide visual field observation during measurement, so that Draw the height change curve of the measurement area;

[0044] It also includes a scraper blade 7, a scr...

specific Embodiment approach 3

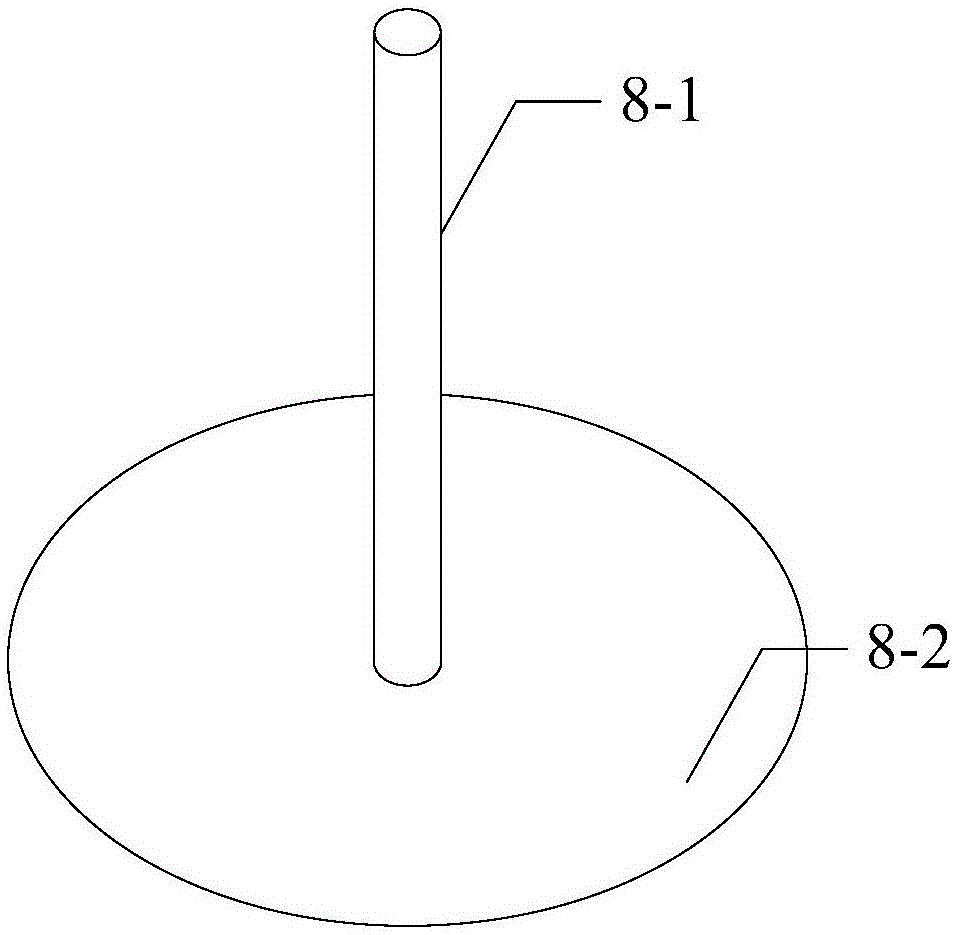

[0051] Specific implementation mode three: combination Figure 4 Describe this embodiment, this specific implementation is based on the method of using the automatic scraping film measurement device of a probe-type film thickness measuring machine described in the first embodiment,

[0052] Include the following specific steps:

[0053] Step 1. Determine the measurement point of the measuring object by searching the CCD3, and perform step 2;

[0054] Step 2. After determining the measuring point, move the measuring needle 5 to the measuring point, draw the height change curve of the measuring area through the pressure sensor above the measuring needle 5 through software processing, and measure the CCD4 for real-time monitoring of the needle volume The measurement process and the measurement position accuracy, perform step three; in step two, according to the height change curve of the measurement area drawn, the film thickness of the measurement object is obtained through sof...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com