Communication type piezoresistive array

An array and electrode array technology, applied in the field of sensors, can solve problems such as the inability to detect pressure and the need to expand the measurement area, and achieve the effects of eliminating measurement blind areas, improving use efficiency and reliability, and expanding the measurement area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

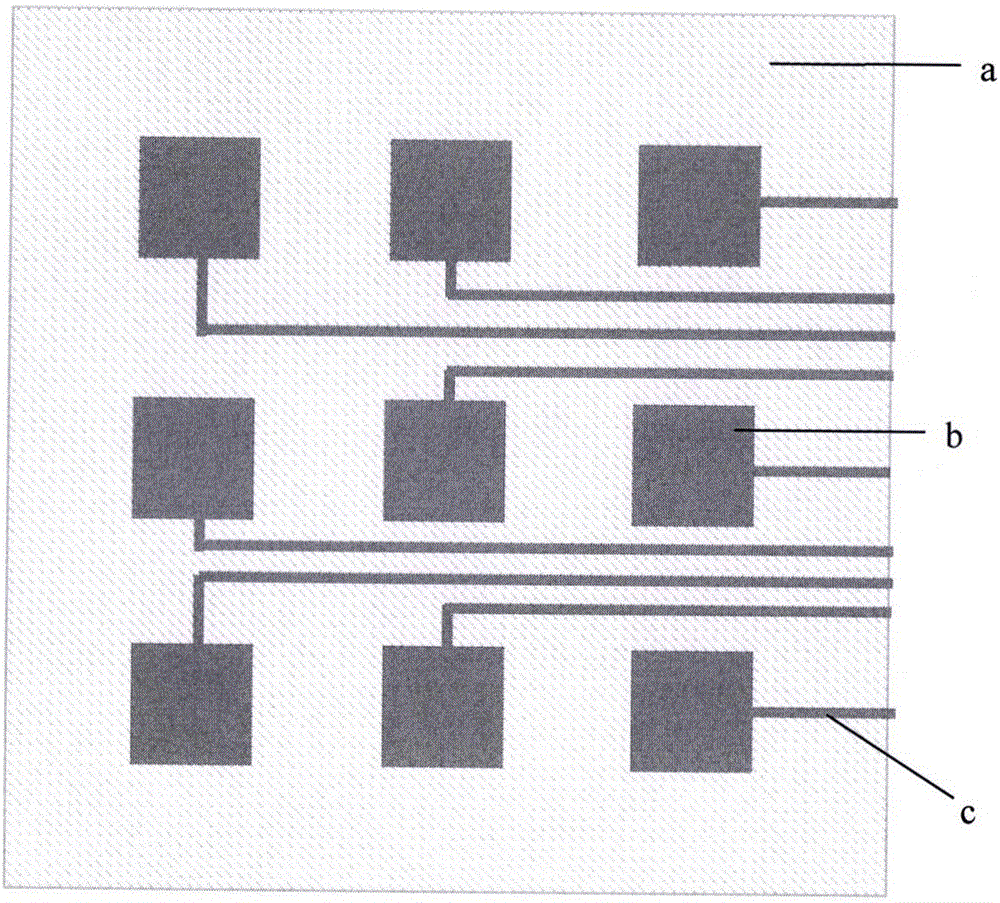

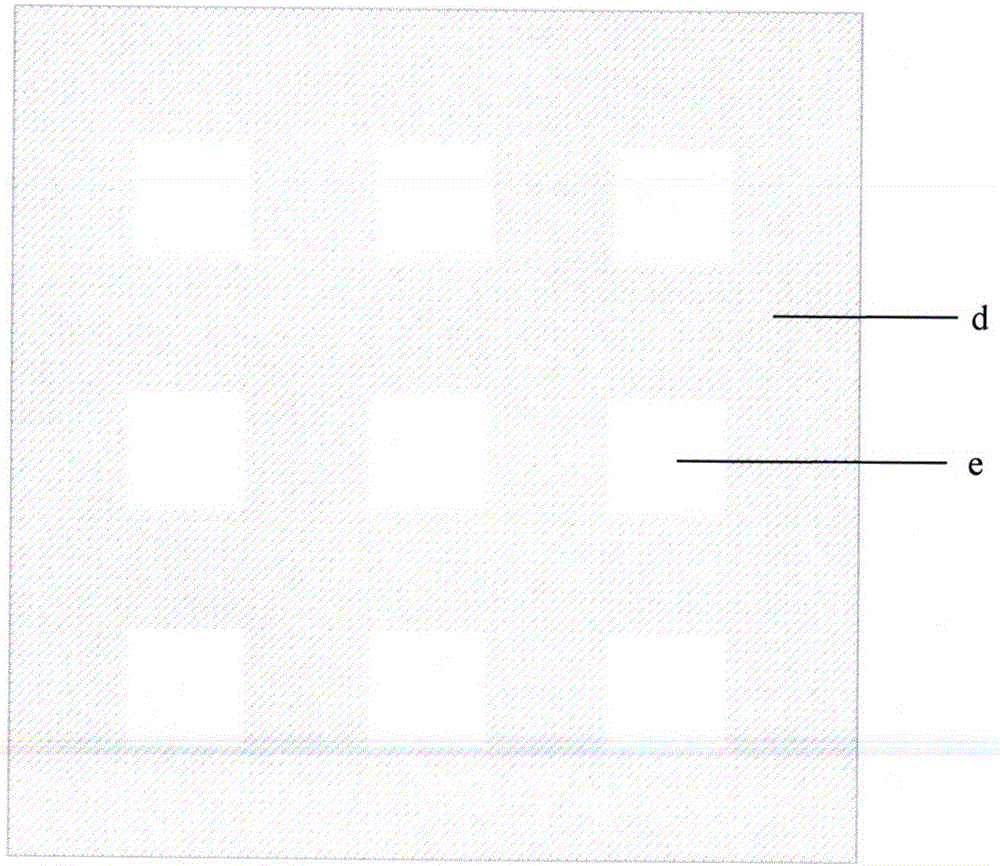

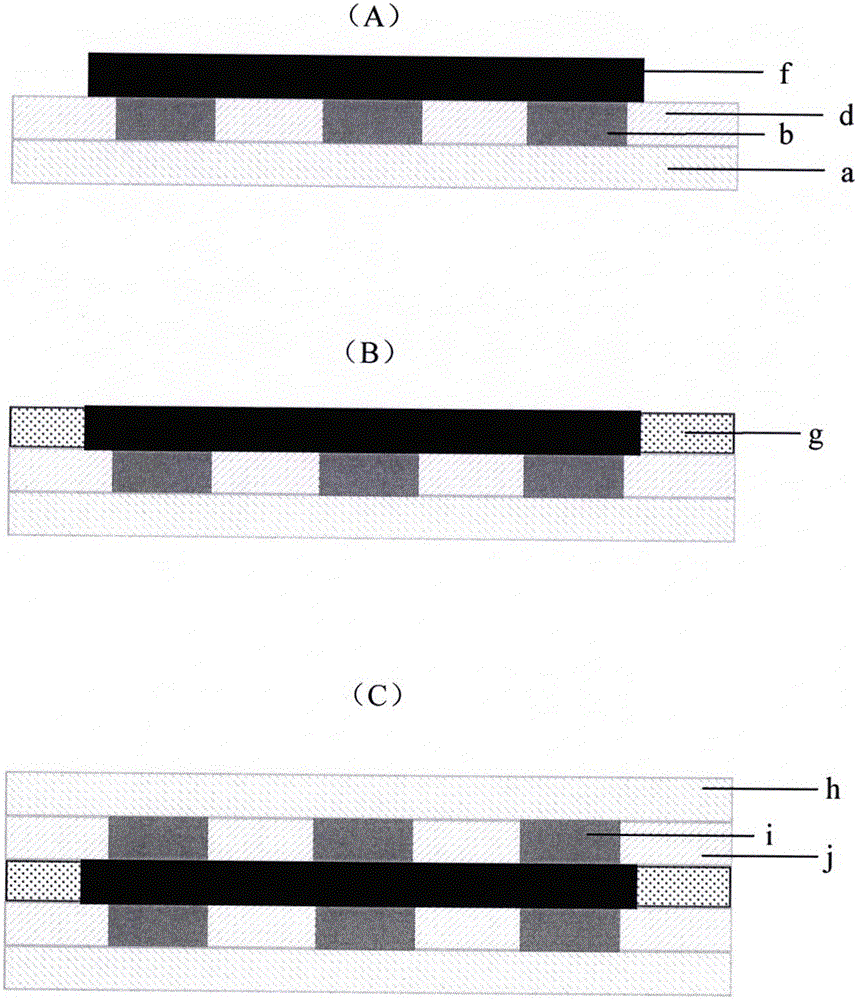

[0013] Lay 3 rows and 3 columns of copper electrode arrays on the surface of a polyimide film as the outer insulating film of the underlying packaging film; open a window on another polyimide film as the inner insulating film of the underlying packaging film, the inner The number and size of the windows on the insulating film are the same as those of the electrodes on the outer insulating film; the inner insulating film with windows and the outer insulating film covered with electrode arrays are laminated together to form the bottom packaging film, and ensure that all The electrodes and the windows are aligned one by one so that all the electrodes are exposed; the carbon black powder and polydimethylsiloxane are mixed by the solution mixing method, and the mass ratio is 0.08:1, and the carbon black is made by extrusion molding Fill the polydimethylsiloxane composite film; cut the carbon black filled polydimethylsiloxane composite film as the piezoresistive sensitive film, so th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com