Pressurizing device for detecting waterproof sealing performance of sensor

A detection sensor, waterproof sealing technology, applied in the direction of using liquid/vacuum for liquid tightness measurement, etc., can solve the problem of effective waterproof sealing performance of the sensor, and achieve the effect of solving the problem of waterproof detection, avoiding water ingress, and ensuring reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

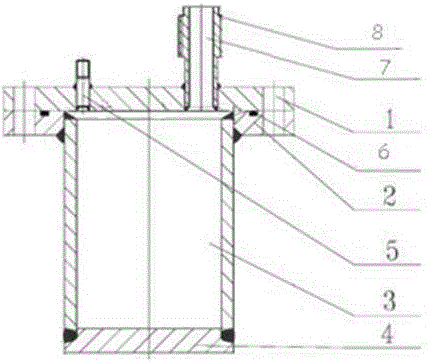

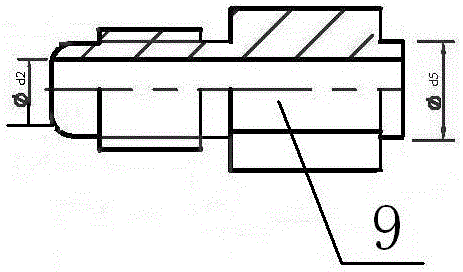

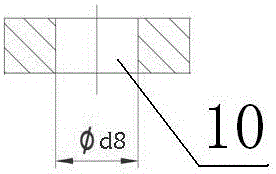

[0023] The present invention includes a supercharging device body used for measuring the waterproof sealing performance of the sensor. The sealing cover 1 of the supercharging device body is provided with an integrally formed supercharging nozzle 5 and a sensor wire outlet nozzle 7. The supercharging nozzle is connected to the external The pressure device is connected, the top of the sensor wire outlet nozzle 7 is connected to the sealing joint 9 through the sealing nut 11, and the through hole Фd212 for leading out the sensor wire is set inside the sealing joint 9, after the sensor wire is led out to the through hole Фd212, Fill the inner through hole Фd212 of the sealing joint 9 with waterproof and pressure-resistant glue, and let it fully cure.

[0024] when used in figure 1 Fill the device with water, put the sensor into the barrel of the supercharging device, the barrel is a stainless steel barrel structure, do a good job of sealing the sensor wire and the wire outlet noz...

Embodiment 2

[0027] This embodiment is preferably as follows on the basis of Embodiment 1: the supercharging device body includes a sealing cover 1, a cylinder flange 2, a cylinder 3 and a bottom plate 4, the bottom of the cylinder 3 is welded to connect the bottom plate 4, and the bottom of the cylinder 3 The top of the cylinder is welded to the flange 2 of the cylinder, the sealing cover 1 is located on the top of the flange 2 of the cylinder, and the flange 2 of the cylinder and the sealing cover 1 are connected by bolts. The barrel and the bottom plate of the supercharger body, and the barrel and the barrel flange are all connected by welding, and the barrel flange and the sealing cover are connected by bolts, using welding or bolts, so that The supercharging device itself has good stability, can withstand higher pressure, and will not leak.

Embodiment 3

[0029] This embodiment is preferably as follows on the basis of the above embodiments: an O-shaped rubber sealing ring groove 6 is also provided on the cylinder flange 2, and an O-shaped rubber sealing ring is installed in the O-shaped rubber sealing ring groove 6 for sealing. Since the cylinder flange and the sealing cover are connected by bolts, in order to prevent water leakage from the gap between the cylinder flange and the sealing cover, an O-shaped rubber sealing ring groove and an O-shaped rubber sealing ring are set up. Sealing treatment prevents water leakage and further improves the accuracy of the device inspection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com