Collaborative Topology Optimization Method for Thin Plate Piezoelectric Smart Structures Based on Precise Deformation Control

A technology of topology optimization and deformation control, applied in constraint-based CAD, design optimization/simulation, electrical digital data processing, etc., can solve the problem of poor deformation accuracy of the overall structure, and achieve the effect of high-precision shape control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

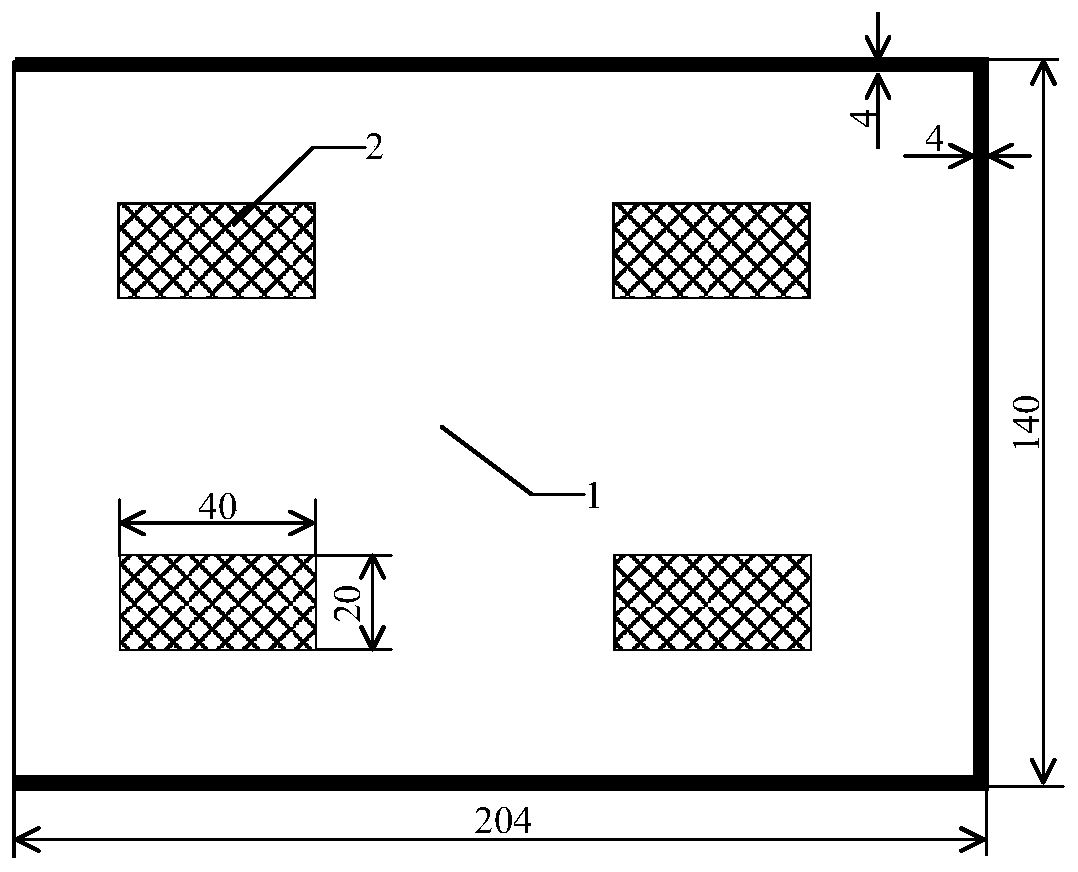

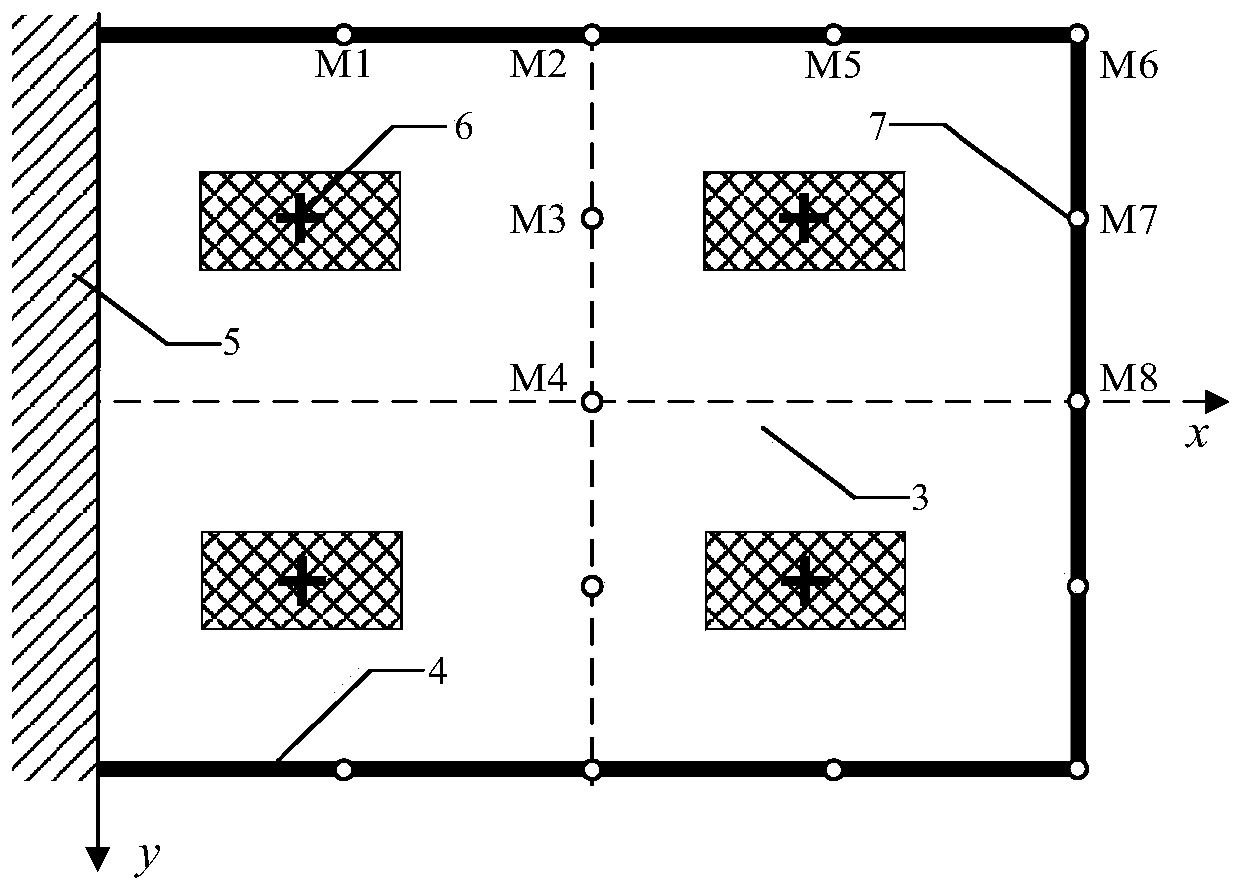

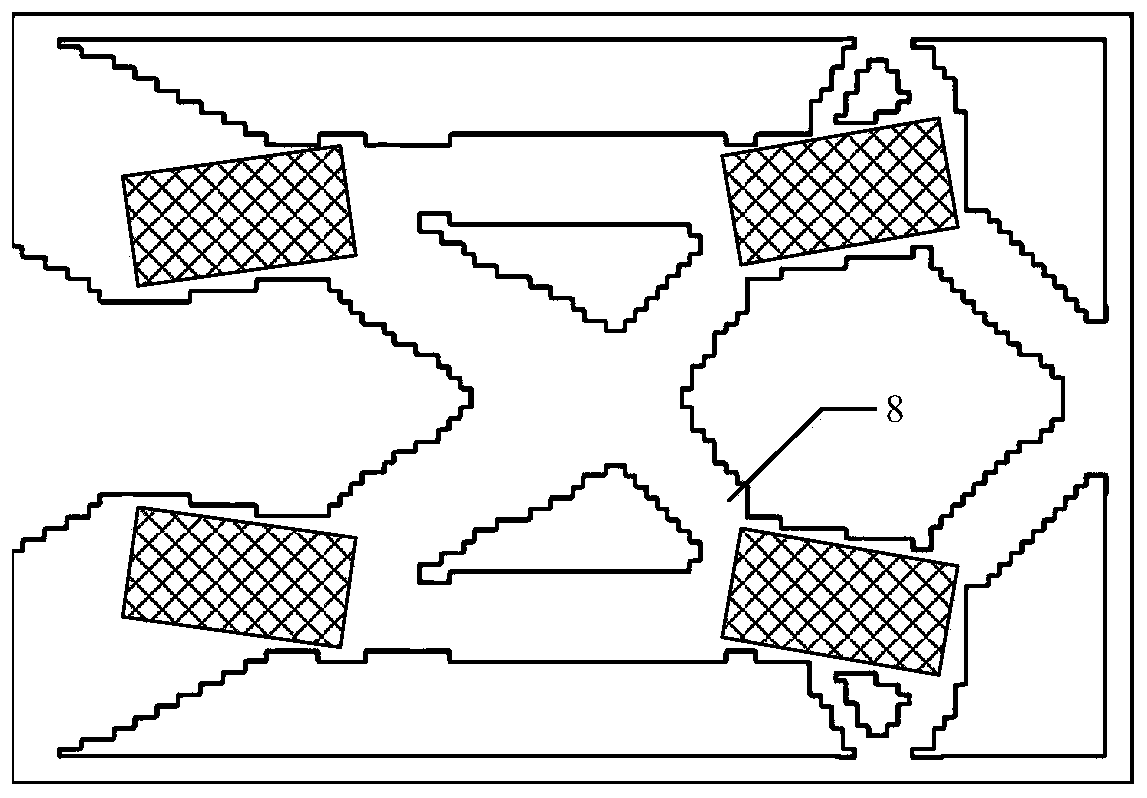

[0026] refer to Figure 1-4 . The specific steps of the collaborative topology optimization design method of thin-plate piezoelectric intelligent structure based on precise deformation control in the present invention are as follows:

[0027] (a) The initial positions of the piezoelectric smart components are (40, 33, 0), (150, -33, 0), (150, 33, 0), (150, -33, 0). The size of the substrate thin plate 1 is 204 mm in length, 140 mm in height, 1 mm in thickness, and 4 mm in non-design region width. Divide the finite element grid for the base thin plate, with a total of 7140 units: among them, the design domain 3 is divided into 6600 units, and the non-design domain 4 is divided into 540 units, and the design domain unit is assigned a pseudo density value of 0.5. The Young's modulus of the sheet material is 70Gpa, and Poisson's ratio is 0.32. The left end of the substrate sheet 1 is fixed to form a fixed boundary 5, and four pairs of rectangular piezoelectric smart components ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com