Ultrasonic vibration assisted machining of axial-bending-torsional coupled vibration horn

A technology of auxiliary processing and ultrasonic vibration, applied in metal processing equipment, fluids using vibration, manufacturing tools, etc., can solve problems such as circulation, and achieve the effect of reducing lateral vibration, lowering temperature, and improving cutting efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

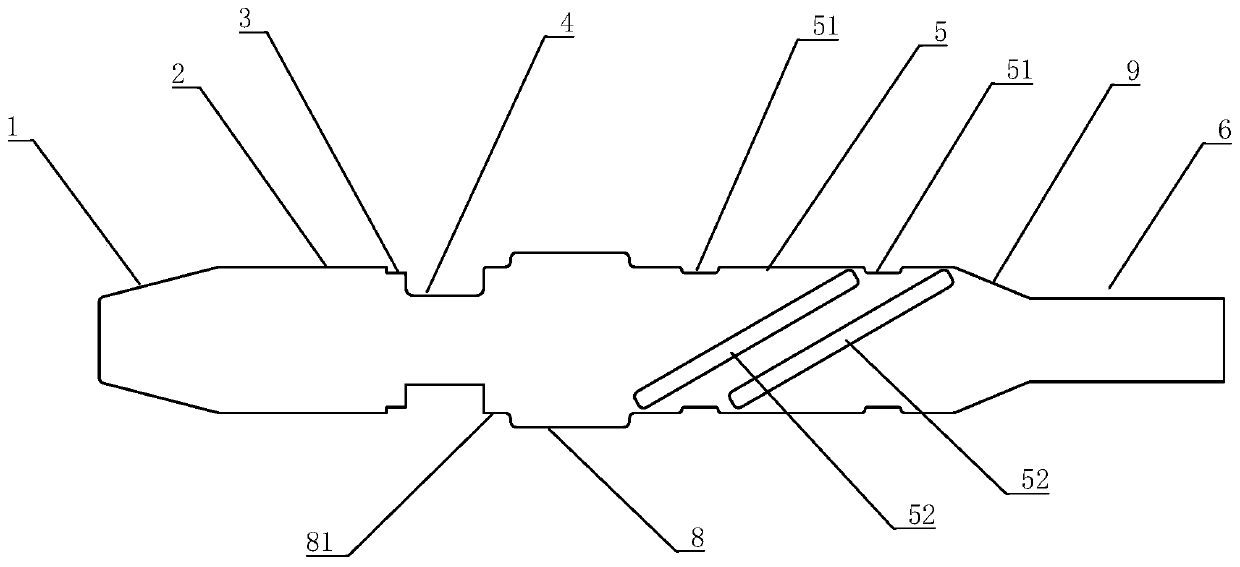

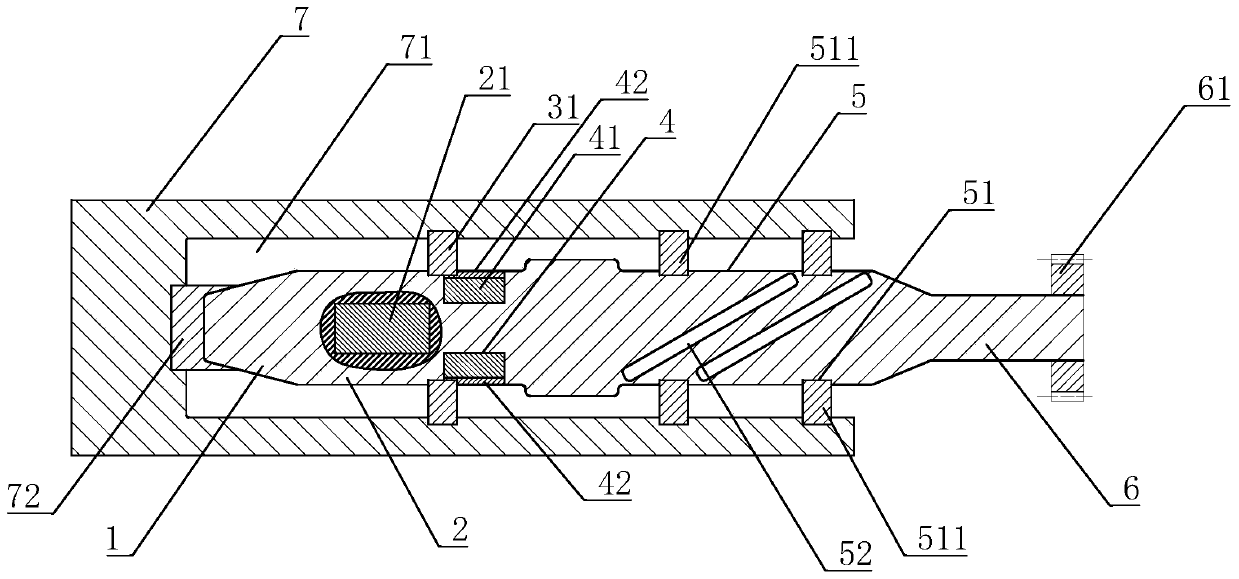

[0022] refer to Figure 1 to Figure 6 , an ultrasonic vibration-assisted machining axial-bending-torsional coupling vibration horn of the present invention, including a matching positioning section 1, a first actuator installation section 2, a second connector installation section 3, The second actuator installation section 4 , the third connector installation section 5 and the cutter gear installation section 6 . The first actuator installation section 2 , the second actuator installation section 4 , the third connector installation section 5 and the cutter gear installation section 6 are all cylindrical.

[0023] The vibration horn is made of titanium alloy, which has less material loss in the working frequency, high fatigue resistance, low acoustic impedance, and can withstand large vibration speed and displacement amplitude. The step-shaped vibr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com