Embedded abrasive cloth reel type sanding machine

A technology of sanding machine and emery cloth, applied in the field of sanding machine, can solve the problems of inability to guarantee the synchronous movement of both ends of the drum, failure to achieve sanding treatment effect, inconvenient operation, etc., so as to improve cutting efficiency and save replacement time. , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

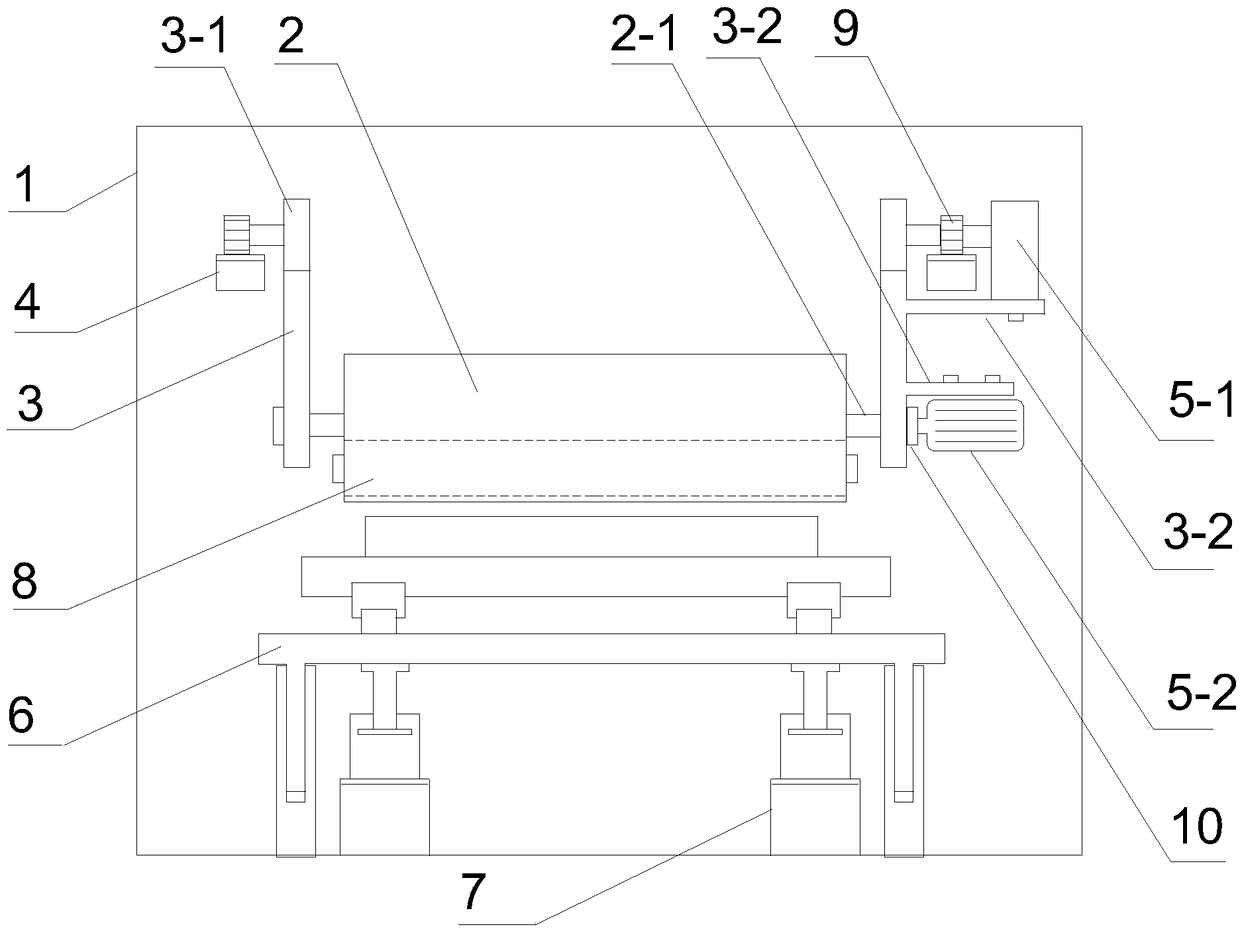

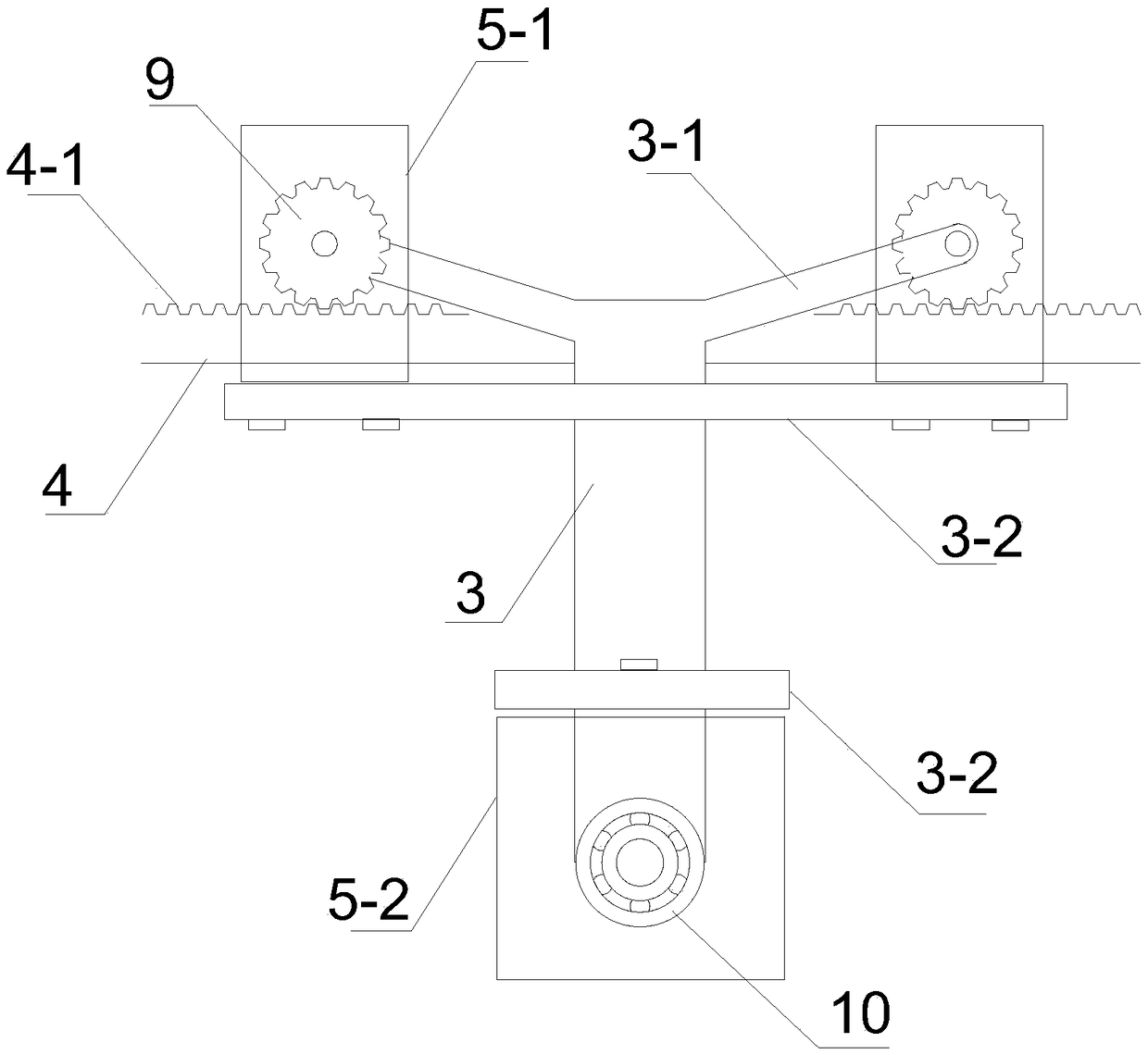

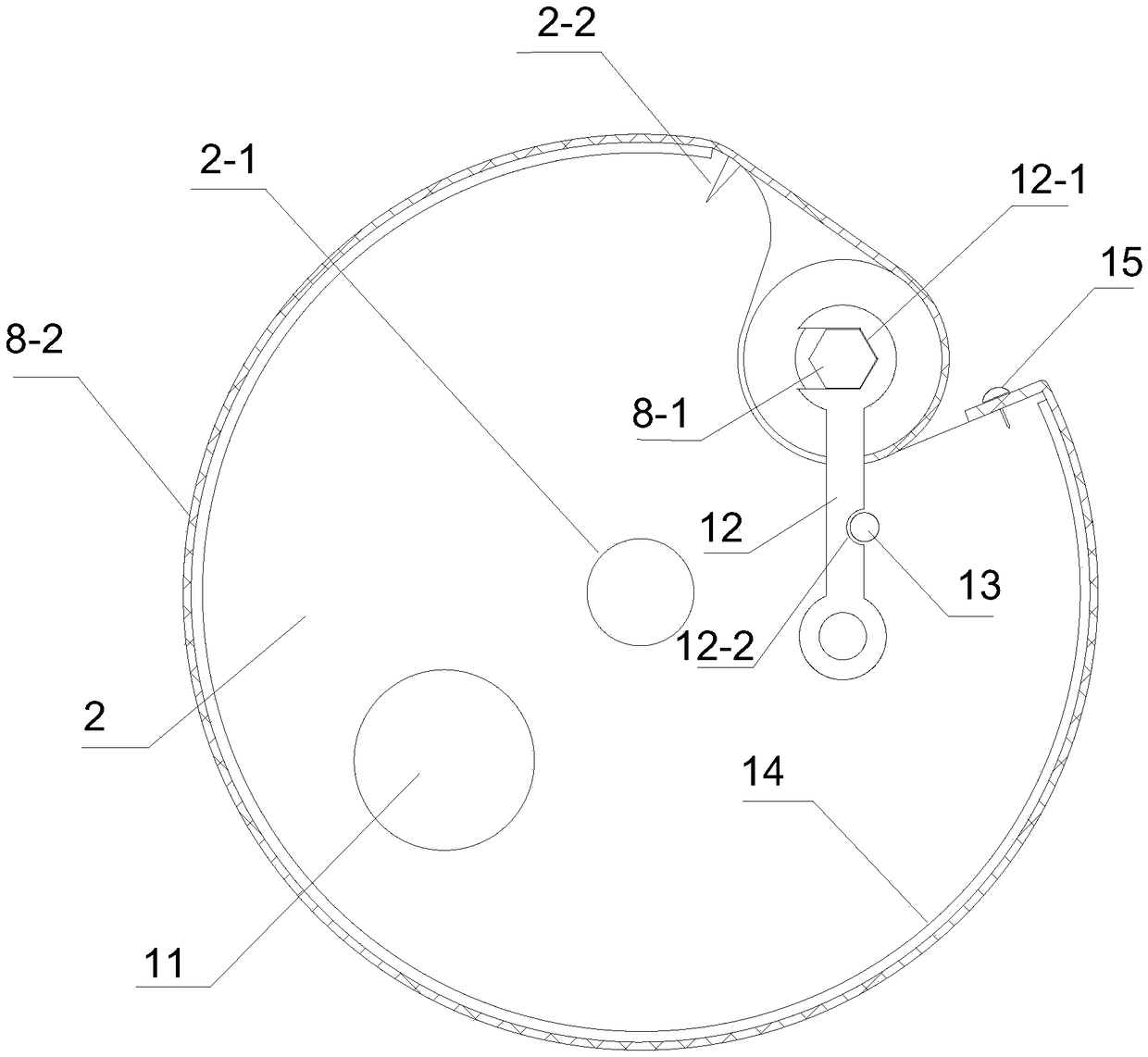

[0026] A drum type sander with embedded emery cloth, comprising a box body 1, and also includes a main drum 2, a boom 3, a beam frame 4, a driving motor 5, a processing platform 6 and a four-column support structure 7 arranged in the box body, the The main drum 2 is embedded with a gauze reel 8, and the two ends of the main drum 2 are provided with a shaft body 2-1, and the top of the boom 3 is connected with a support arm 3-1 which is inclined upward to both sides, The end of the support arm 3-1 extends laterally outwards and is connected with a gear 9. The beam frame 4 is erected inside the box body 1, and the beam frame 4 is provided with a rack 4-1 meshing with the gear 9. , the bottom of the boom 3 is provided with a ball bearing 10, the boom 3 is also provided with a side mounting plate 3-2, and the driving motor 5 is connected to the side mounting plate 3-2, wherein the first driving motor 5 -1 drives the gear to rotate, the output shaft of the second driving motor 5-2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com