Ultrathin fingerprint identification system-level packaging piece adopting through silicon via and bare die for molding

A system-level packaging and fingerprint recognition technology, which is applied to electrical components, electric solid-state devices, semiconductor devices, etc., can solve problems such as the distance between the lifting sensing area and the outside of the package, and the lack of integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

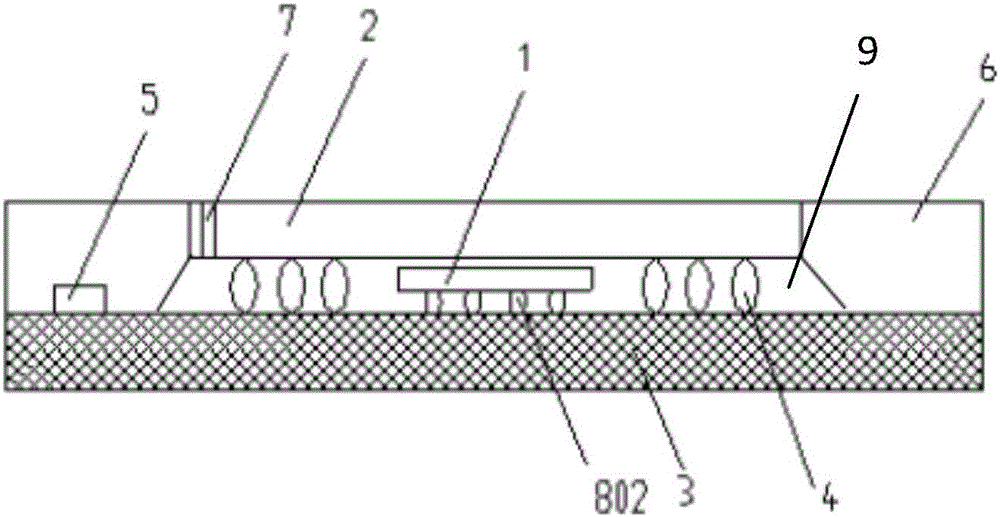

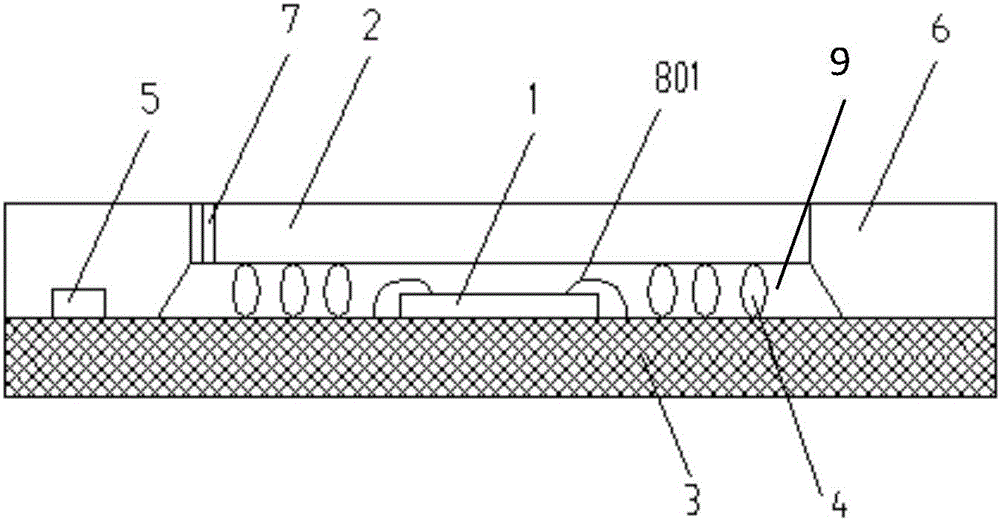

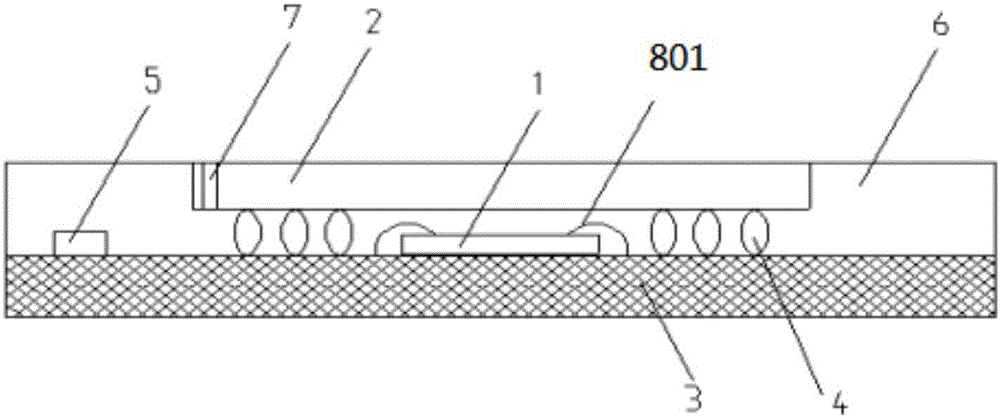

[0015] An ultra-thin fingerprint identification system-level package adopting through-silicon vias and bare core plastic packaging, including a sensor chip 2, solder balls 4, filling glue 9, a substrate 3, and a plastic package 6, and the sensor chip 2 runs through There are through-silicon vias 7 , the sensor chip 2 is connected to the substrate 3 through solder balls 4 , the filler 9 fills the area between the solder balls 4 , and the plastic package 6 wraps the sensor chip 2 , the filler 9 and most of the substrate 3 . The package has components 5 connected to the substrate 3 , which are arranged side by side on the same substrate 3 with the sensor chip 2 and wrapped by a plastic package 6 . The package has a functional chip 1, the functional chip 1 is located in the space between the back of the sensing chip 2 and the substrate 3, and is connected to the substrate 3 through solder balls 802, and the filling glue 9 covers the functional chip 1 and the solder balls 802. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com