Lead acid storage battery electrode and battery as well as manufacturing method, component and device

A lead-acid battery and electrode manufacturing technology, applied in the direction of lead-acid battery electrodes, battery electrodes, battery components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

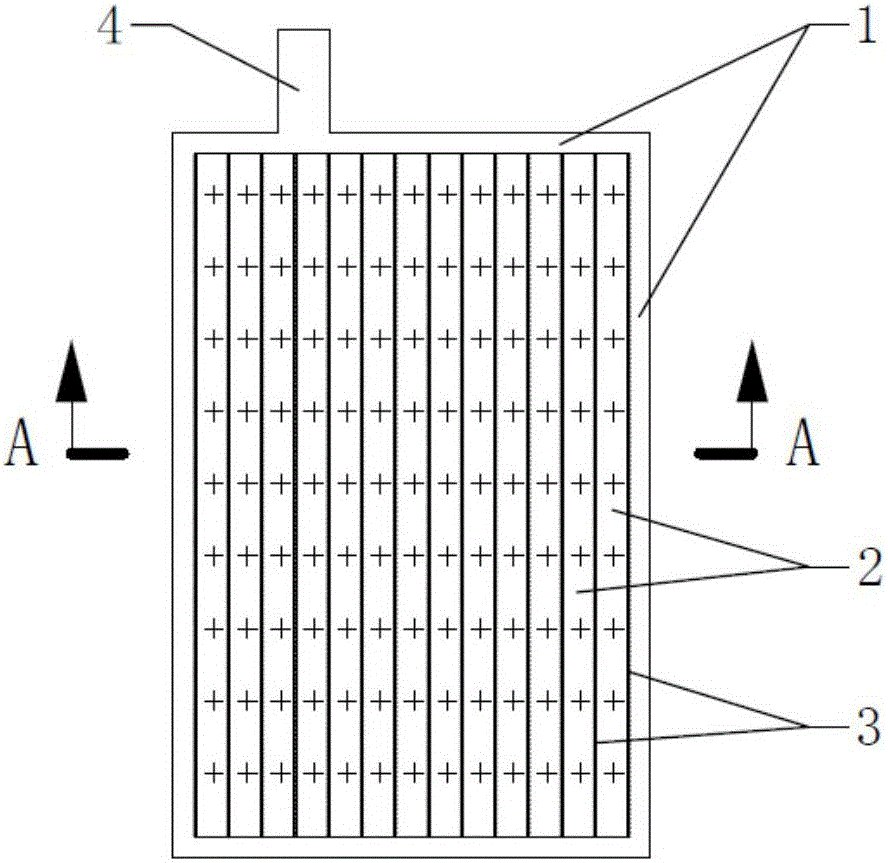

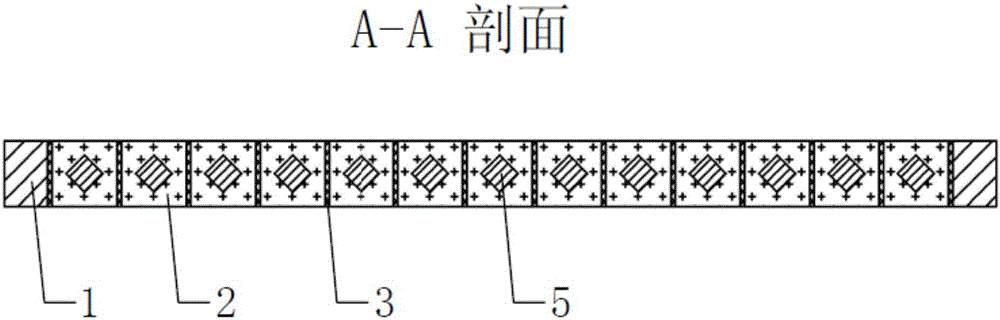

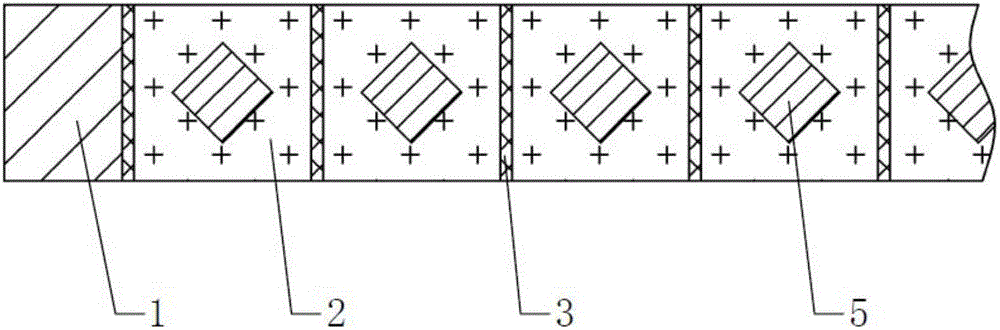

[0088] The present embodiment has the positive electrode of the plate-type lead-acid storage battery of stable void body, as figure 1 , 2 , 3, its grid current collector frame 1 frames the positive electrode active material 2 and 14 rectangular columnar strip-shaped stable voids 3 filled with AGM porous materials, and each stable void is a hexahedron. Through the inside of the electrode and the front and back of the flat electrode plane, there is a positive electrode active material 2 column between every two stable voids 3, and at the same time, there is a stable void 3 between every two positive active material 2 columns, There is a stable void body 3 between a positive electrode active material 2 column and a current collector frame 1 at the frame 1 of the current collector. The AGM multi-porous material in the stable void body 3 is used to fully fill the gap and is used for mechanical support, The positive electrode active material 2 on both sides of the stable void body ...

Embodiment 2

[0098] The present embodiment has the positive electrode of the plate-type lead-acid storage battery of stable void body, as Figure 6 , 7 As shown, its current collector frame 1 frames the positive electrode active material 2 and 4 stable voids 7 filled with multi-hole glass sheets and trapezoidal in radial section. Each stable void is hexahedral and does not penetrate The interior of the electrode and the front and back of the plate plane, two stable voids 7 are distributed on the front or back of the electrode, and the multi-hole glass sheet is used to mechanically support and fix the positive electrode active material 2 adjacent to the stable voids 7 . The overall dimensions of the positive electrode of the flat lead-acid battery with stable voids in this embodiment are length × width × thickness: 60 mm × 35 mm × 2 mm, and the radial section of each of its stable voids has a trapezoidal upper bottom length × lower The bottom length × height is: 0.3mm × 3mm × 0.4mm, and th...

Embodiment 3

[0106] The first negative electrode of the flat lead-acid storage battery with stable voids in this embodiment, such as Figure 9 As shown, its current collector frame 1 frames the negative electrode active material 8 and 2484 stable voids 9 filled with multi-porous PE plastic cylindrical particles, and the cylinders of each stable void 9 are axially aligned with The electrode planes are perpendicular to each other, and do not penetrate the inside of the electrodes and the front and back sides of the flat plane, and each stable void body 9 is more than Figure 9 The form of the medium matrix is distributed on the front and back of the electrode, and the position of a 3×4 primary matrix basically corresponds to the position of a grid collector grid, and the spacing between each primary matrix basically corresponds to the grid The position of the conductive rib 5 of the current collector grid, such as Figure 10 shown. The multi-porous PE plastic particles filled with the cy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com