Fruit ripening system

A ripening and fruit technology, applied in the fields of fruit and vegetable preservation, food science, food preservation, etc., can solve the problem of high energy consumption and achieve the effect of increasing the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

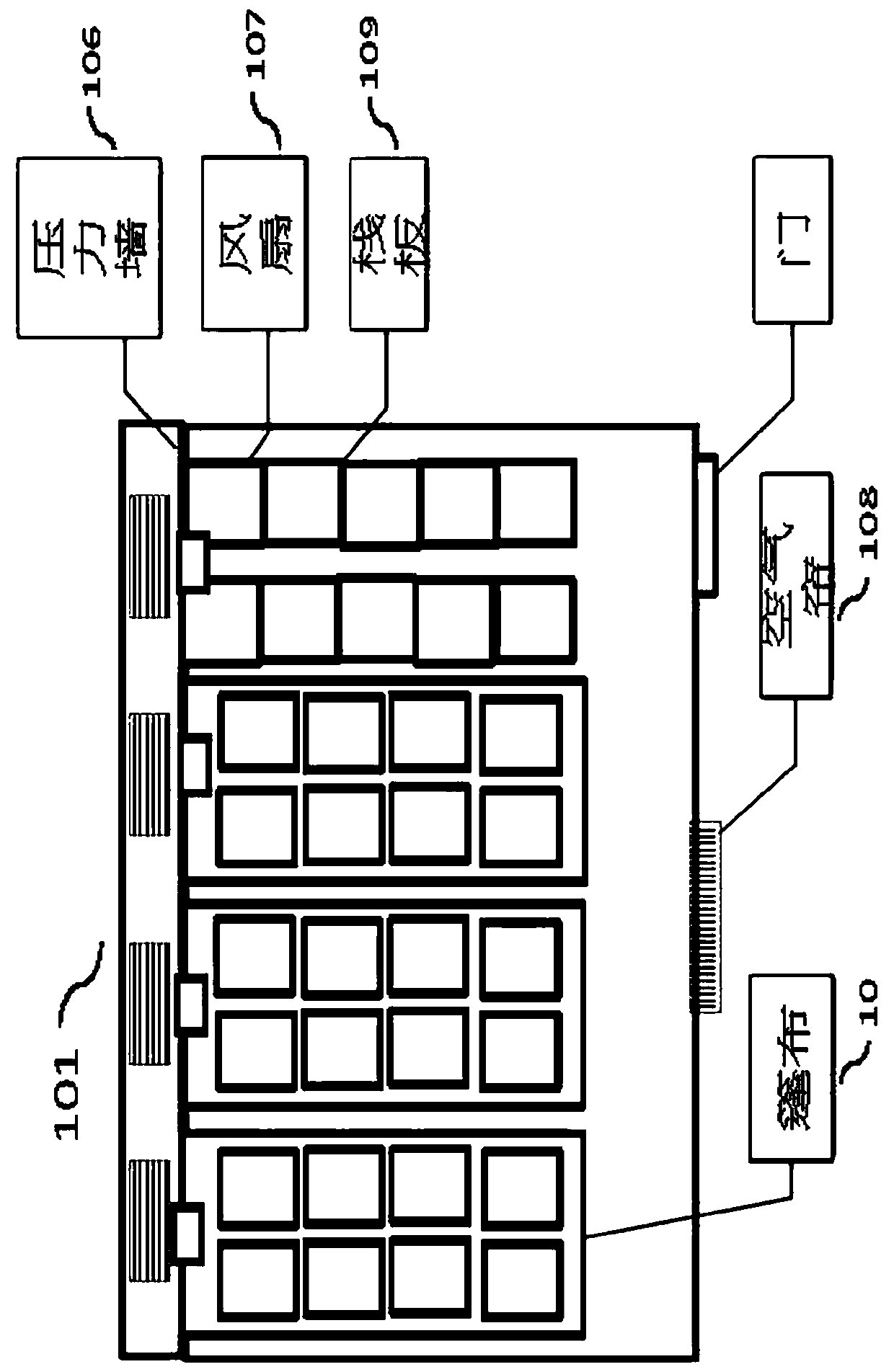

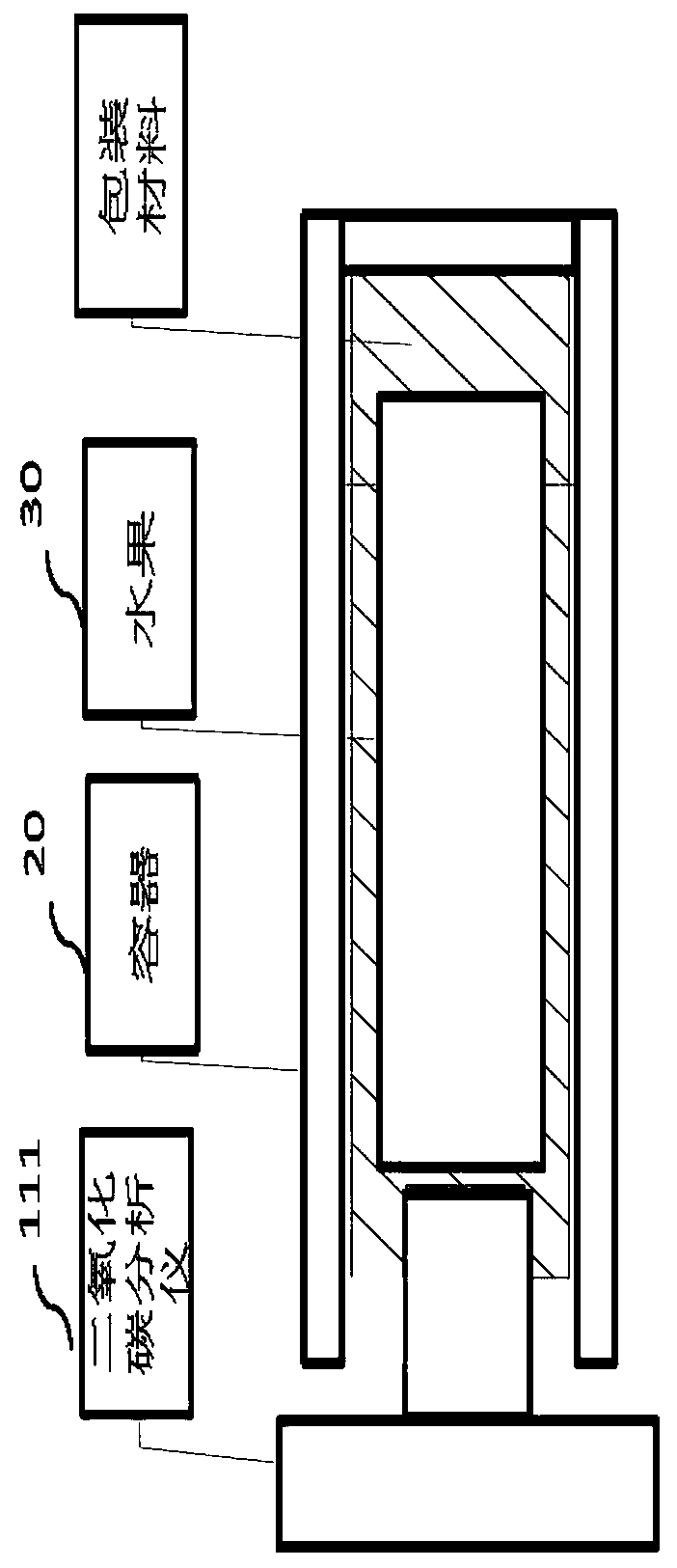

[0024] see Figure 1 to Figure 3The fruit ripening system (100) shown includes a gas chamber (101) and a ripening chamber (102). The gas chamber (101) includes a plurality of pressurized air units (103), an ethylene gas monitoring device (104) and an ethylene supply device (105), wherein the pressurized air unit (103) includes a pressure wall (106), fan (107), air curtain or screen (108), fruit-carrying pallet (109) or fruit-covering tarpaulin (10); Pressure wall (106) and tarpaulin (10); or use fan (107) to control the airflow on the fruit pallet (109); or use an air curtain or curtain of flexible material on one side of the fruit pallet (109) (108), through the construction of the pressurized air unit (103), the ethylene gas is passed through the fruit-carrying pallet (109) to accelerate the ripening of the fruit. And use the tarpaulin (10) as the partition with other pressurized air units (103). The ripening chamber (102) is for fruit ripening. The fruit ripening system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com