Salt drainage method adopting high-strength underground pipes and application of salt drainage method in improvement of interpenetrated saline-alkali soil in North China

A high-intensity, dark-tube technology, applied in application, soil preparation methods, climate change adaptation, etc., can solve the problem of bauhinia blight resistance rate is not obvious, increase the photosynthetic area, can not prolong the flowering period of bauhinia, etc. problems, to achieve the effect of improving greening and aesthetic value, increasing photosynthetic area, and improving greening and aesthetic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1 A kind of salt drainage underground pipe

[0042] The salt-discharging underground pipe comprises the following components in parts by weight:

[0043] 82 parts of homopolypropylene, 30 parts of polyvinyl chloride, 15 parts of ABS resin, 2.5 parts of viscose, 1.1 parts of candlewood wax, 5.3 parts of paraffin wax, 0.4 parts of dioctyl phthalate, 0.27 parts of mica, guaiac 0.22 parts of resin, 0.33 parts of maleic anhydride grafted polyethylene.

Embodiment 2

[0044] Embodiment 2 A kind of salt drainage underground pipe

[0045] The salt-discharging underground pipe comprises the following components in parts by weight:

[0046] 88 parts of homopolypropylene, 37 parts of polyvinyl chloride, 28 parts of ABS resin, 4.2 parts of viscose, 2.2 parts of candlewood wax, 5.8 parts of paraffin wax, 1.2 parts of dioctyl phthalate, 0.39 parts of mica, guaiac 0.38 parts of resin, 0.40 parts of maleic anhydride grafted polyethylene.

Embodiment 3

[0047] Embodiment 3 A kind of salt drainage underground pipe

[0048] The salt-discharging underground pipe comprises the following components in parts by weight:

[0049] 93 parts of homopolypropylene, 43 parts of polyvinyl chloride, 32 parts of ABS resin, 7.6 parts of viscose, 2.8 parts of candlewood wax, 6.4 parts of paraffin wax, 1.6 parts of dioctyl phthalate, 0.49 parts of mica, guaiac 0.51 parts of resin, 0.49 parts of maleic anhydride grafted polyethylene.

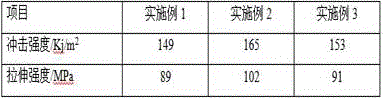

[0050] Table 1 is the result of the performance test carried out to the salt discharge underground pipe described in embodiment 1-embodiment 3

[0051]

[0052] From the above test results, it can be seen that the performance of the salt discharge underground pipe described in Example 2 is the best, and Example 2 is a preferred embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com