Centrifugal micro-fluidic control chip

A microfluidic chip and centrifugal technology, applied in fluid controllers, laboratory utensils, laboratory containers, etc., can solve the problems of difficult to realize siphon valves, and achieve the effect of wide application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

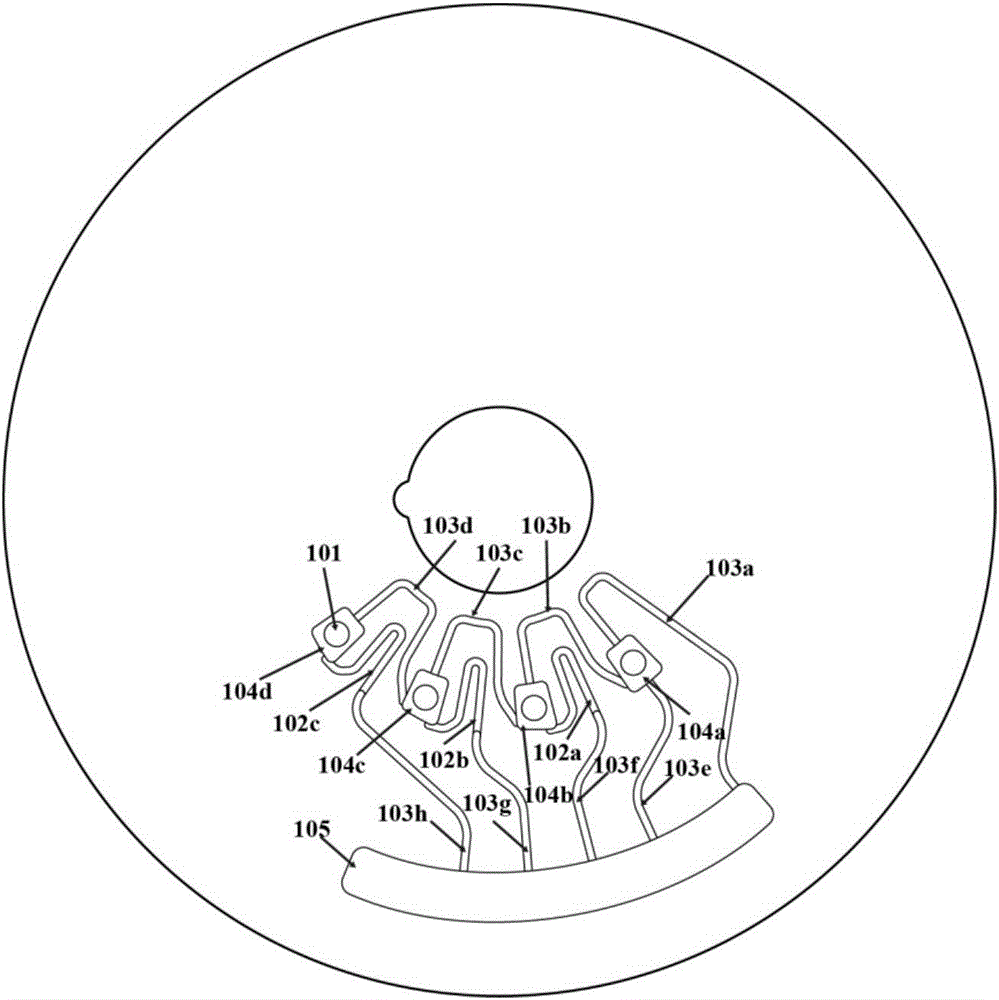

[0034] Sample injection hole 101, first siphon (102a, 102b, 102c), first connecting pipe (103a and 103e), second connecting pipe (103b, 103c and 103d), fifth connecting pipe (103f, 103g and 103h), Sample loading chamber (104a, 104b, 104c and 104d), collection chamber 105, such as figure 1 As shown, in order to distinguish the various components, in this embodiment, the components of the same structure are only distinguished by different numbers, and the content in parentheses behind the components is the same component with different numbers, so as to facilitate review.

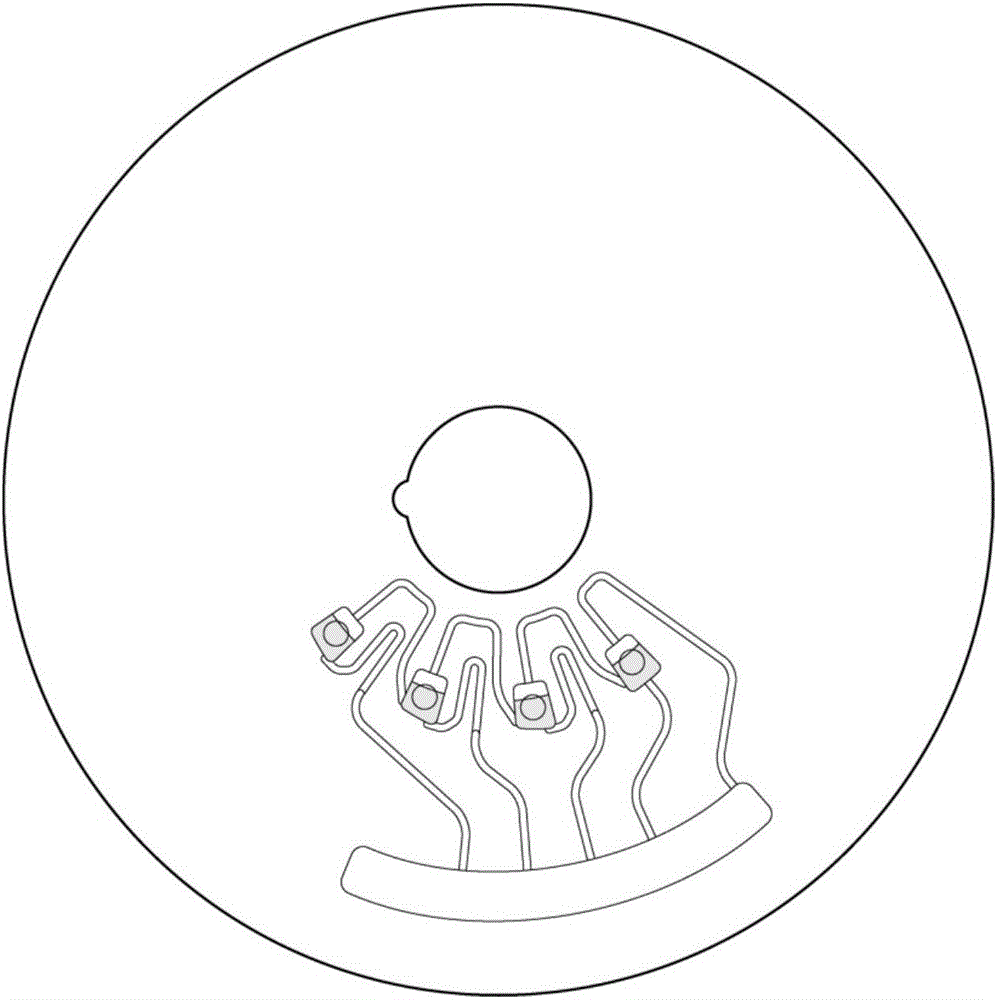

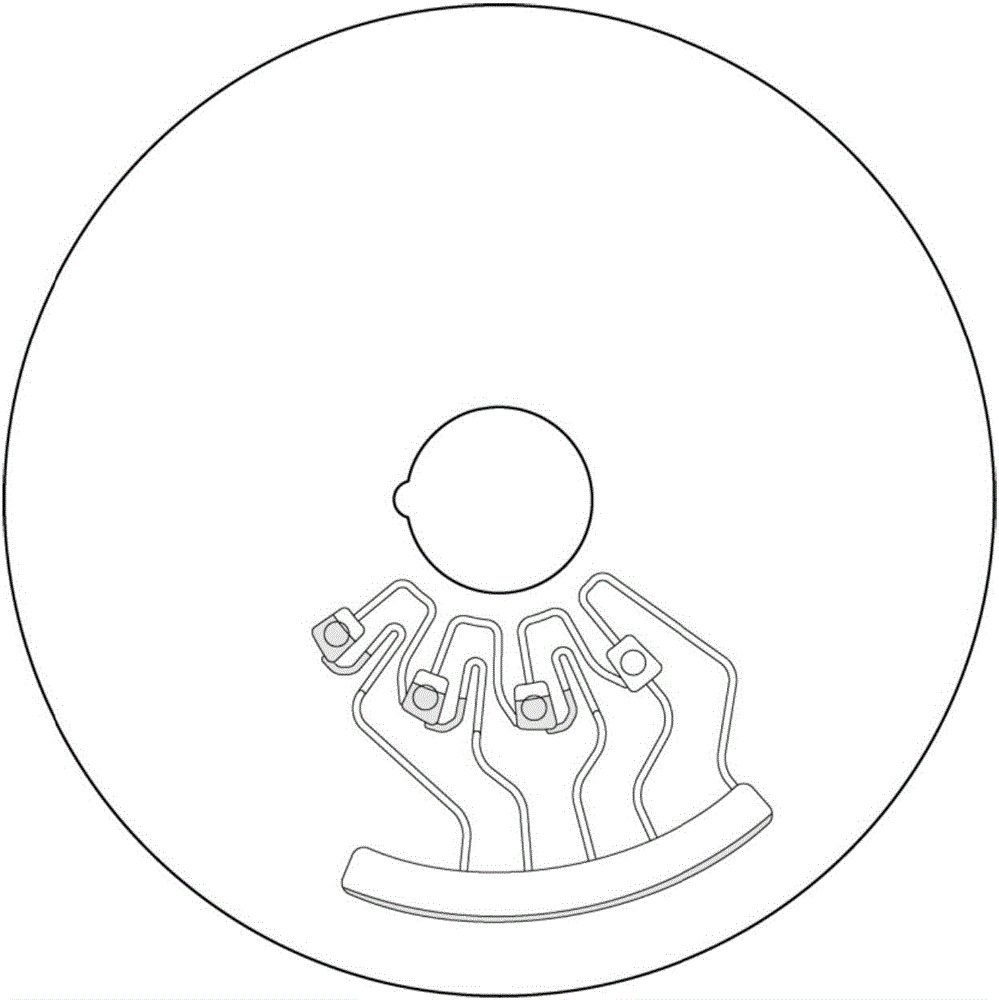

[0035] Wherein, the first siphon tube 102a, the first siphon tube 102b and the first siphon tube 102c are all hydrophilically modified, and the second connecting tube 103b, the second connecting tube 103c and the second connecting tube 103d are hydrophobically modified. During the experiment, add water from the sample hole into the corresponding sample chamber, such as Figure 2a As shown in the figure, it c...

specific Embodiment 2

[0037] Sample injection hole 301, first siphon (302a, 302c), second siphon (302b, 302d), first connecting pipe (303a and 303b), second connecting pipe (303c and 303d), third connecting pipe (303f) , the fourth connecting pipe (303g), the fifth connecting pipe (303e), the sample adding chamber (304a, 304b and 304c), the mixing chamber 305, the collecting chamber (306a, 306b), such as image 3 As shown, in order to distinguish the various components, in this embodiment, the components of the same structure are only distinguished by different numbers, and the content in parentheses behind the components is the same component with different numbers, so as to facilitate review.

[0038] Among them, the first siphon 302a, the first siphon 302c and the second siphon 302d are hydrophilically modified, only the part of the second siphon 302b close to the collection chamber 306a is hydrophilicly modified, and the second connecting pipe 303d is hydrophobically modified. During the experi...

specific Embodiment 3

[0040] Sample injection hole 501, first siphon (502a, 502c), second siphon (502b, 502d), first connecting pipe (503a and 503b), second connecting pipe (503c and 503d), third connecting pipe (503f) , the fourth connecting pipe (503g), the fifth connecting pipe (503e), the sample adding chamber (504a, 504b and 504c), the mixing chamber 505, the collecting chamber (506a, 506b), such as Figure 5 As shown, in order to distinguish the various components, in this embodiment, the components of the same structure are only distinguished by different numbers, and the content in parentheses behind the components is the same component with different numbers, so as to facilitate review.

[0041] Wherein, the first siphon tube 502c and the second siphon tube 502d are hydrophilically modified, the first siphon tube 502a and the second siphon tube 502b are not hydrophilically modified, and the second connecting tube 503d is hydrophobically modified. The liquid operation process is similar to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com