Structure-reinforced metal magnetic liner plate

A metal magnetic, reinforced technology, applied in grain processing and other directions, to achieve the effect of increasing the strength of the magnetic field, improving the characteristics of the magnetic field, and strengthening the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

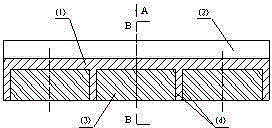

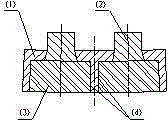

[0019] figure 1 , figure 2 and image 3 Shown is an embodiment of a structurally reinforced metal magnetic liner of the present invention, which consists of a shell (1), a strip-shaped wear-resistant magnet (2), a magnetic block group (3) and an adhesive.

[0020] The shell (1) is made of non-magnetic metal material, and the shape is a box shape composed of a plurality of cubic grids (4), and each grid (4) is arranged in an array aligned horizontally and vertically. One side of lattice (4) is closed, and the other side is open, and the size just accommodates a group of magnetic block groups (3).

[0021] The magnetic block group (3) is composed of 1 to 10 magnetic blocks, and the magnetic block material is a permanent magnetic material. The magnetic blocks are attracted to each other along the thickness direction or bonded together with an adhesive, and the thickness of the magnetic blocks can be equal or different. The number of magnetic block groups (3) is equal to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com