Ore sorting process and equipment based on image recognition technology and mechanical arm

A technology of mechanical arm and image recognition, which is applied in the ore sorting process and the industry field, can solve the problems of picking gangue and manual inspection of gangue, and achieve the effects of saving manpower, material and financial resources, high work efficiency, and improving recovery rate and utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

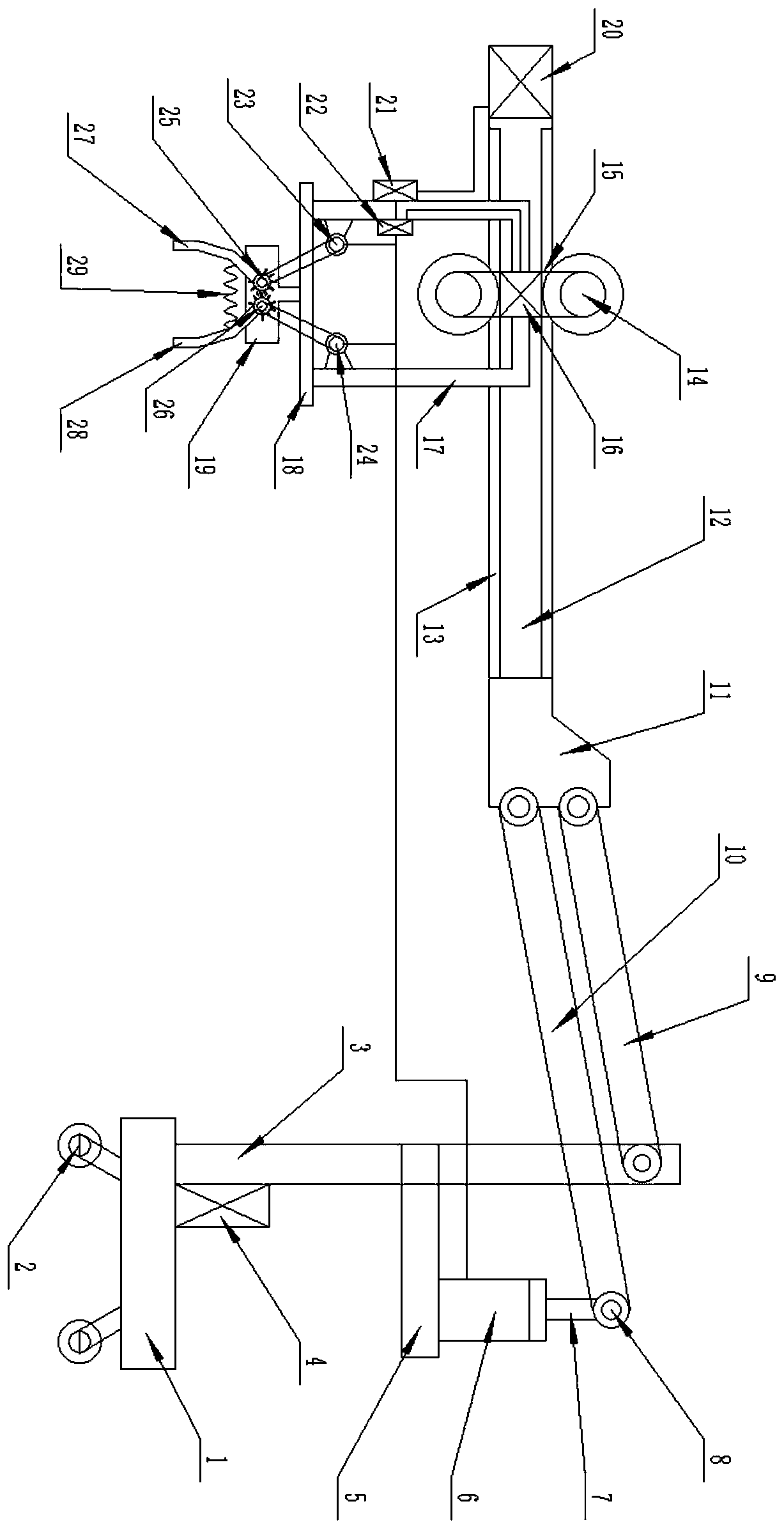

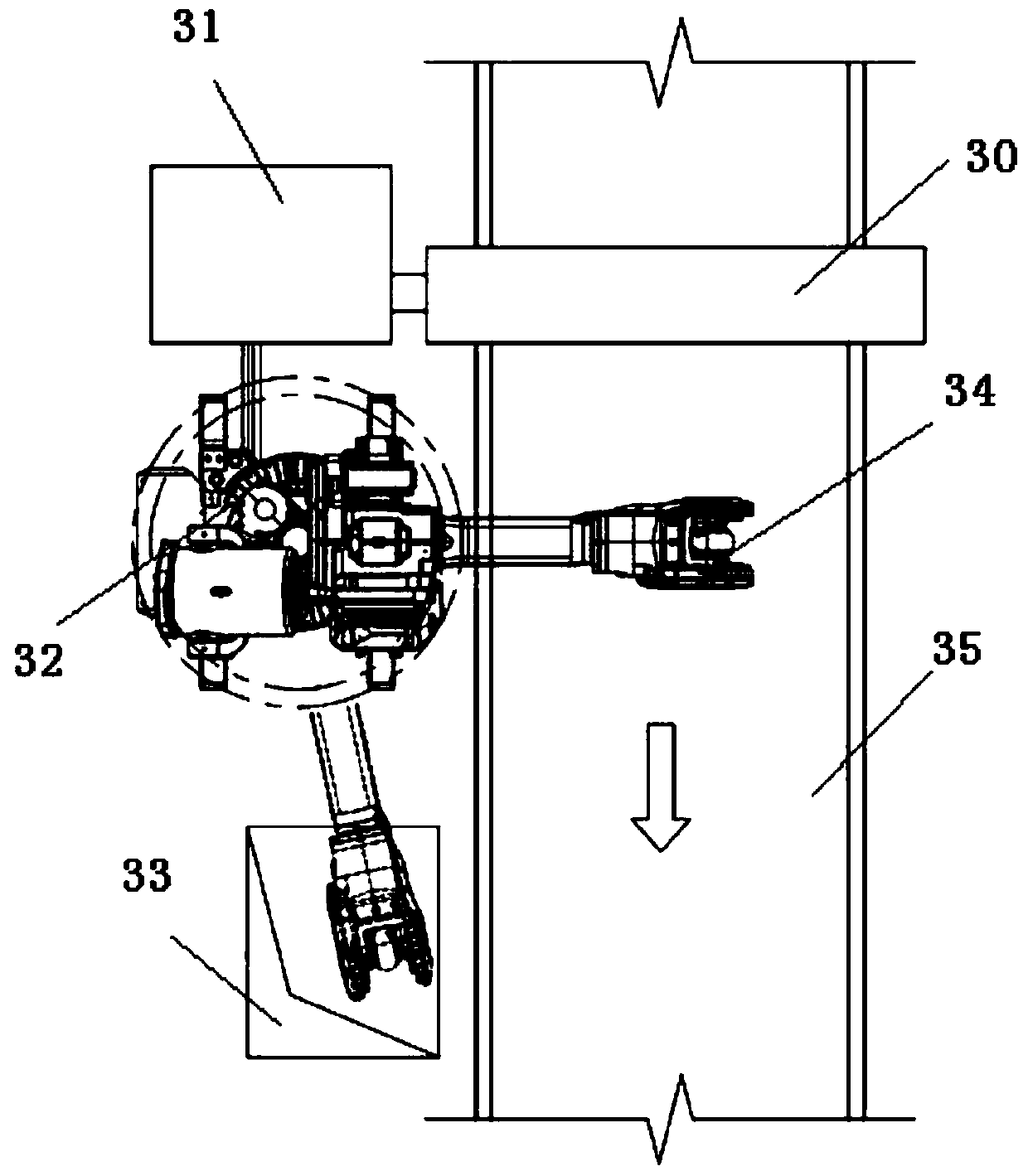

[0049] like figure 1 As shown, this specific embodiment adopts the following technical solutions: a kind of ore sorting process based on image recognition technology and mechanical arm, including the following steps: after various ores pass through the primary screening, a part of them enters the belt for gangue picking, and the image recognition system will The gangue or valuable ore in the gangue belt is distinguished, and the information is transmitted to the controller. The controller controls the mechanical arm to perform the picking action, and the mechanical arm picks out the gangue or valuable ore that needs to be separated according to the recognition result, and discharges it from the chute set outside the mechanical arm.

[0050]The specific structure of the mechanical arm with image recognition function is: including base 1, universal wheel 2, column 3, tool box 4, fixed seat 5, air bar 6, push rod 7, rotating shaft 8, driven rod 9, active rod 10 , movable seat 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com