Thick plate rolling mill filled with particle damping and filling method of thick plate rolling mill

A particle damping and particle filling technology, which is applied in the direction of metal rolling, metal rolling, roll safety equipment, etc., can solve the problems of metal flow balance imbalance, particle damping friction collision, expansion, etc., to reduce downtime maintenance time and improve Modal damping ratio, the effect of great economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

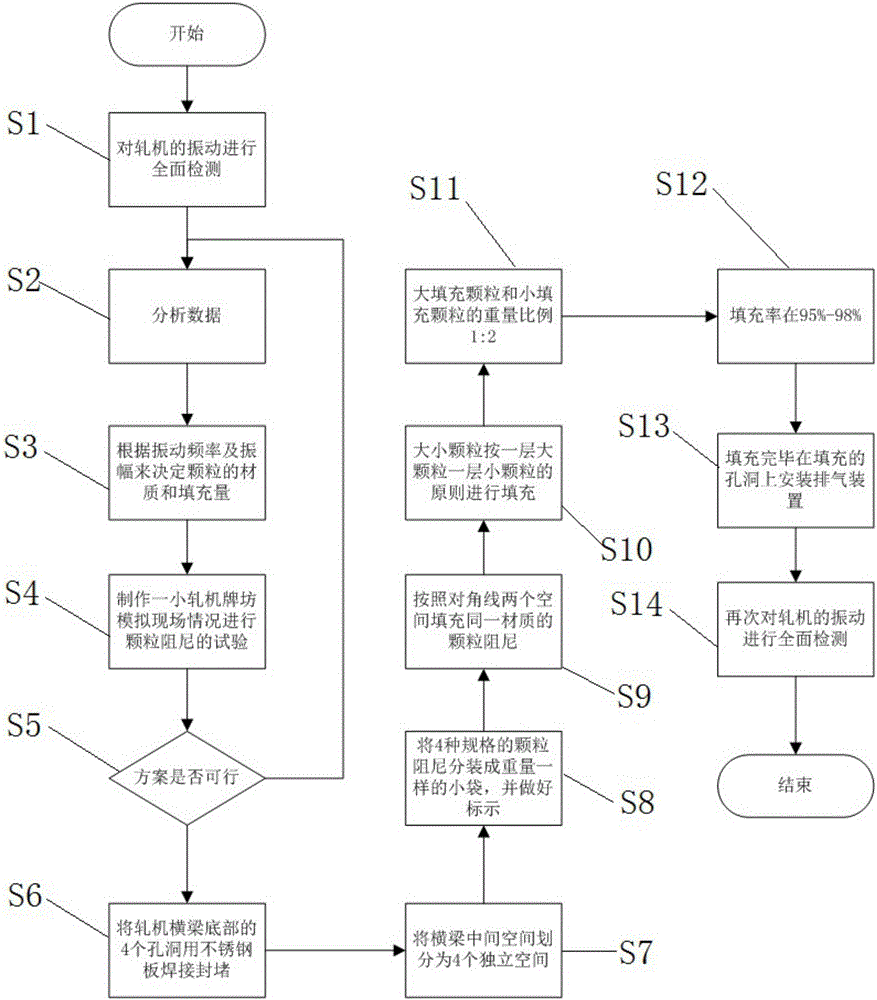

[0025] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

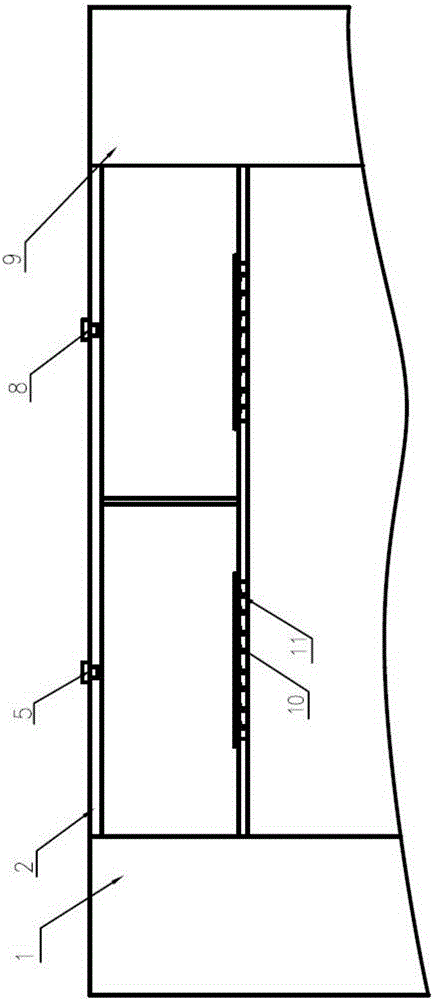

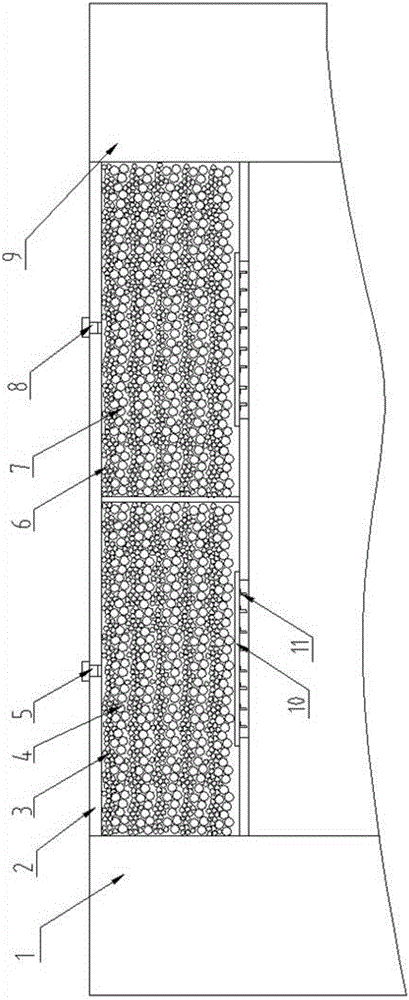

[0026] refer to Figure 1a and 1b , the present invention firstly discloses a thick plate rolling mill filled with particle damping, the main structure of which includes rolling mill beams, rolling mill archway, exhaust device, particle damping, blind plate, blind plate reinforcing rib plate and so on.

[0027] Such as Figure 1a and 1b As shown, the rolling mill includes two upper and lower rolling mill beams, and the upper and lower rolling mill beams and the rolling mill archway form a filling space for particle damping. Specifically, the middle space between the rolling mill archway and the rolling mill beam is the filling space, and the filling space is divided into four sections. There is an exhaust device on the beam of the upper rolling mill, which is connected to the filling space of particle damping, and a blind pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com