A multi-directional controllable split flow forging forming method for excavator bucket teeth

A technology of bucket teeth and bucket teeth of excavators, which is used in manufacturing tools, forging/pressing/hammer devices, forging/pressing/hammering machines, etc. problems, to avoid cracking and local wear, complete metal streamline organization, and improve service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

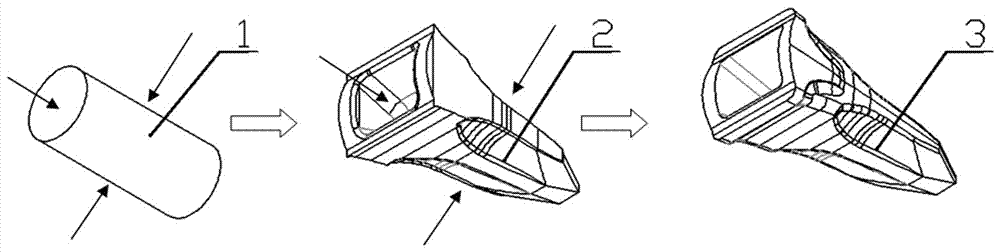

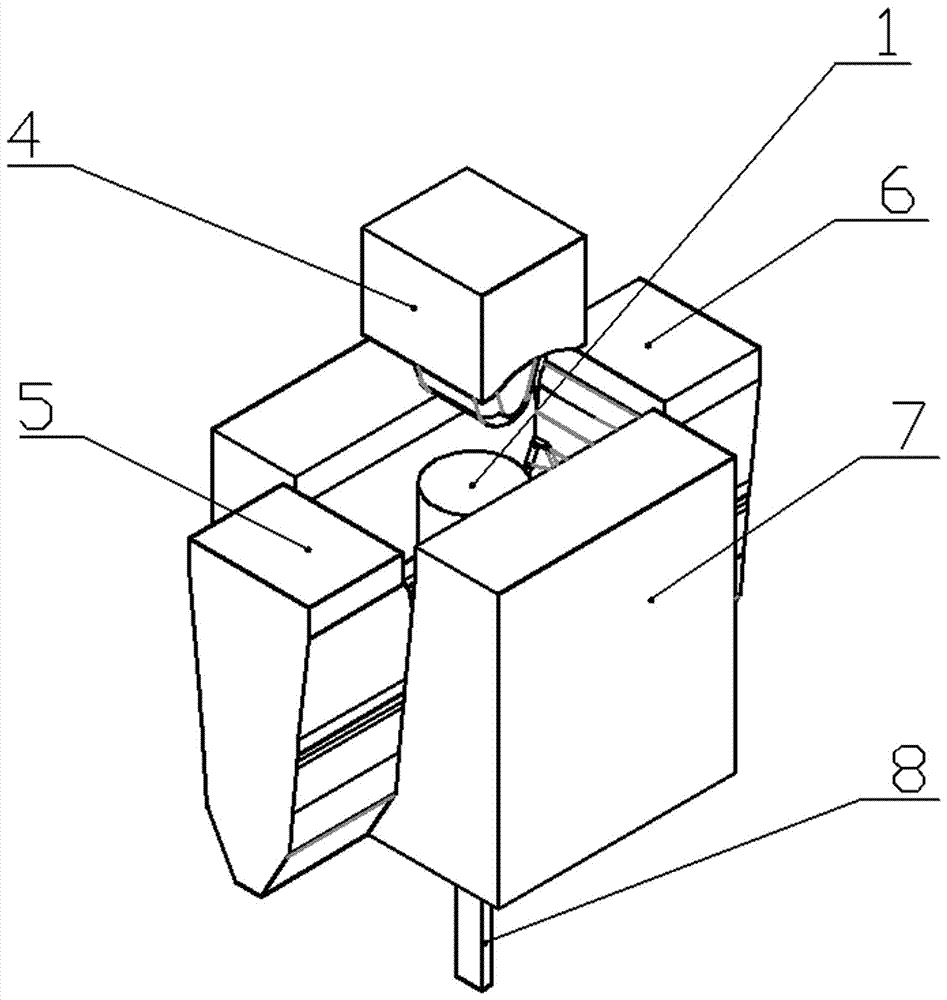

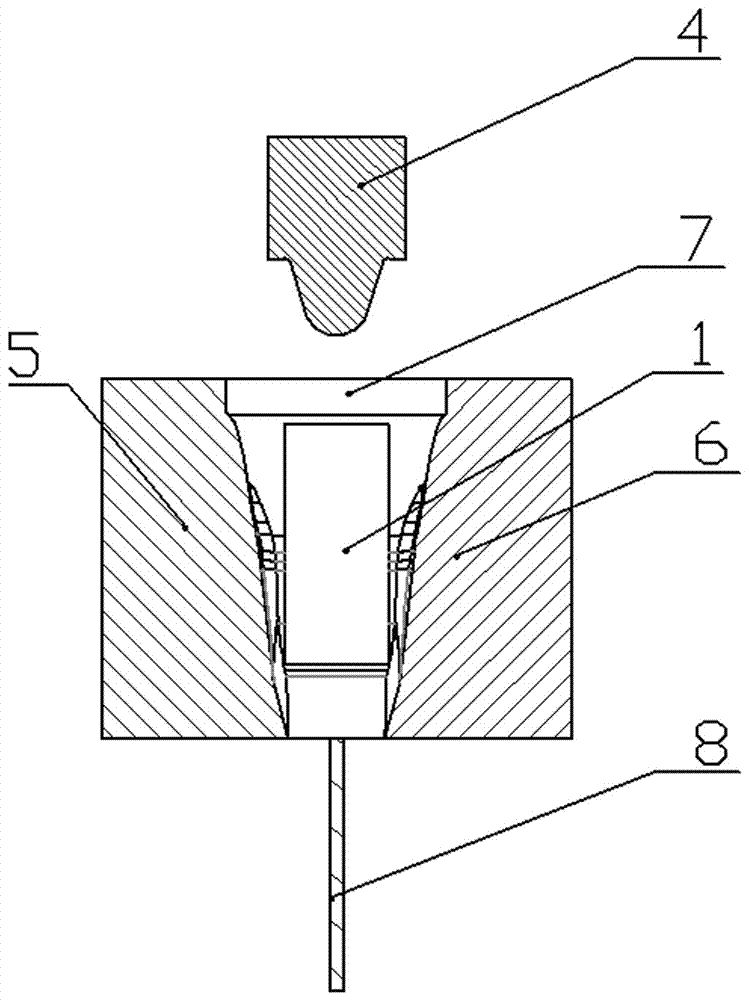

[0040] Example: Combined Figure 1-7 , The total weight of the bucket teeth of this excavator is 13.77kg, the total length is 344.8mm, and the depth of the installation hole is 144mm. There is a negative stripping slope at the tip end, and the conventional forging method cannot be stripped.

[0041] Pre-forging steps:

[0042] (1) Put the metal bar 1 heated to the forging temperature into the cavity of the pre-forging die, then press the pre-forging upper punch 4 to the predetermined middle position and press the end face of the metal bar 1 to complete the positioning of the metal bar 1 ;

[0043] (2) Pre-forging left and right punches 5, 6 extrude the metal bar 1, so that the metal flows to the lower end of the die cavity under the joint action of the pre-forging upper punch 4 and the pre-forging left and right punches 5, 6;

[0044] (3) When the pre-forging left and right punches 5 and 6 reach the predetermined middle position, the metal diverted to the lower part of the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com