Milling cutter for forming boss and boss forming method

A boss and milling cutter technology, applied in milling cutters, milling machine equipment, details of milling machine equipment, etc., can solve the problems of small cutting feed, weak tool rigidity, small machining tool diameter, etc., to reduce the process and cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

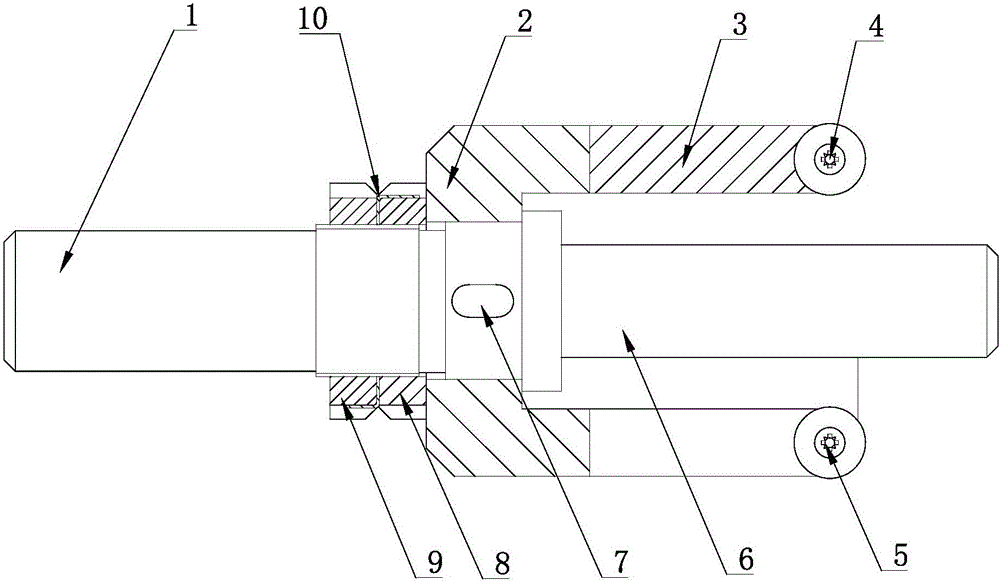

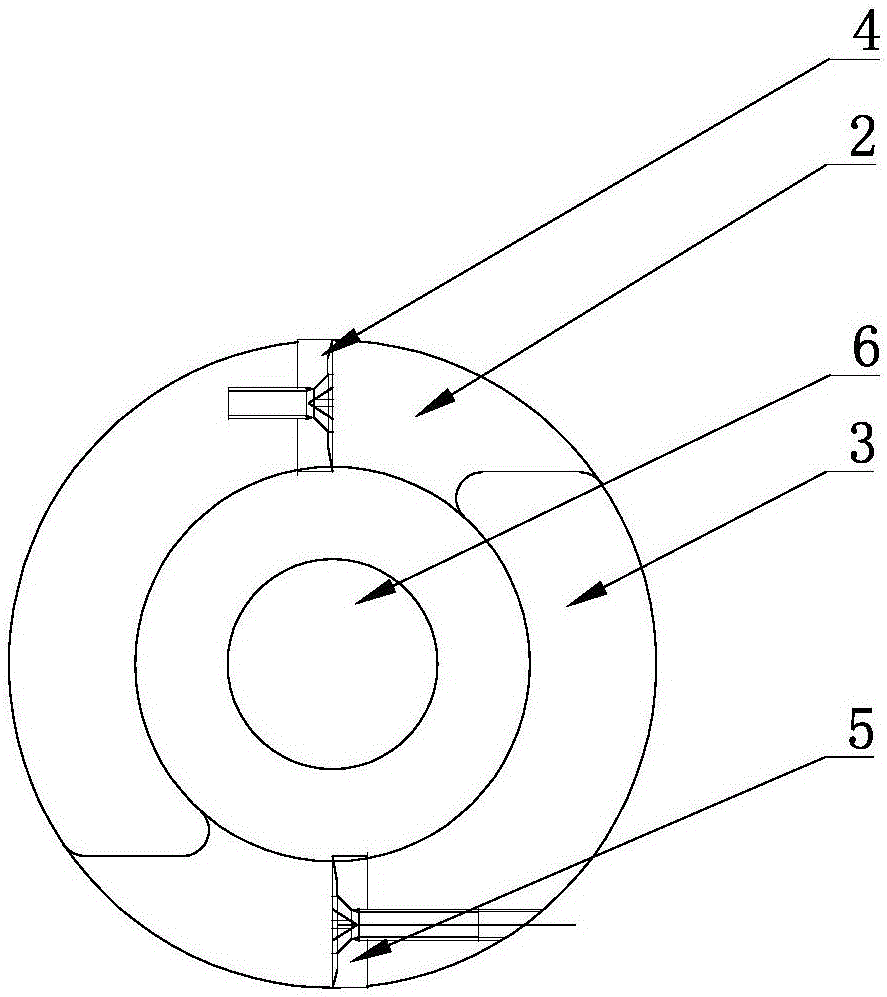

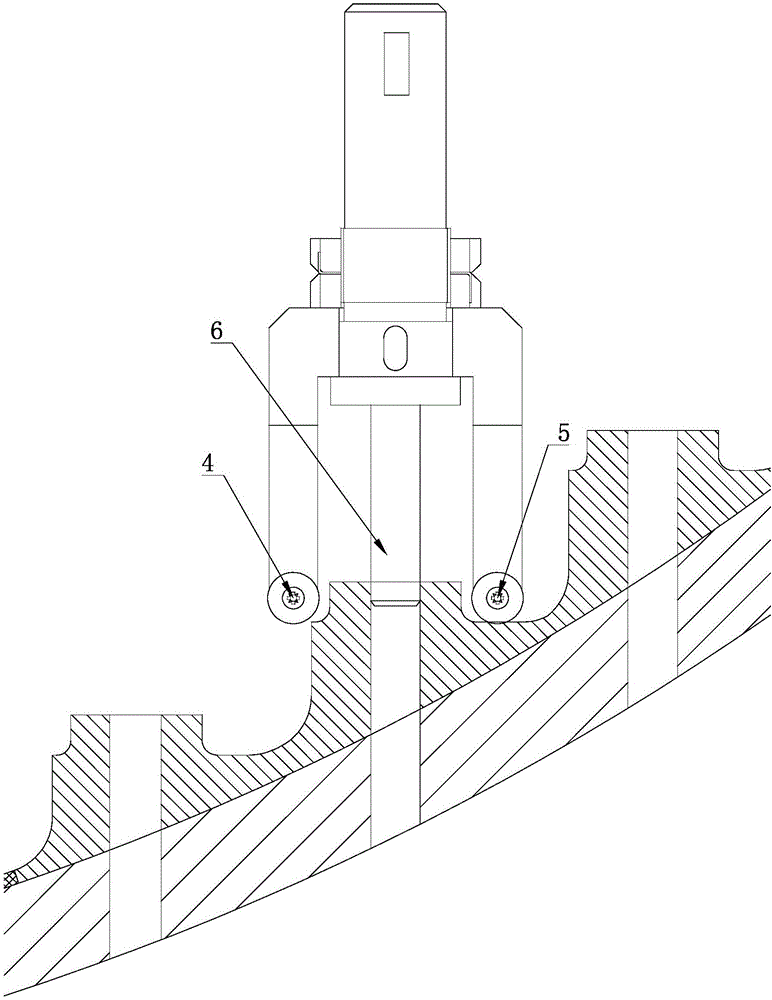

[0018] like Figure 1-2 The shown milling cutter for boss forming includes cutter bar 1 and tool holder 2. The rear part of cutter bar 1 is provided with a connecting part connected with the machine tool. The connecting part is provided with a flat keyway, and tool bar 1 passes through the connecting part. It is fixed on the three-jaw chuck of the machine tool and driven by the machine tool spindle.

[0019] The rear part of the tool holder 2 is a hollow ring structure, so that the tool holder 2 can be set on the front of the tool holder 1, ensuring that the cutter holder 1 and the cutter holder 2 are coaxial, and the space between the cutter holder 2 and the cutter holder 1 is detachable Connection, two handles 3 are arranged on the hollow ring structure of the knife holder 2.

[0020] The above-mentioned knife handle 3 is an arc-shaped plate structure, and its thickness is equal to the thickness of the hollow ring. The arc-shaped knife handle structure can strengthen the wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com