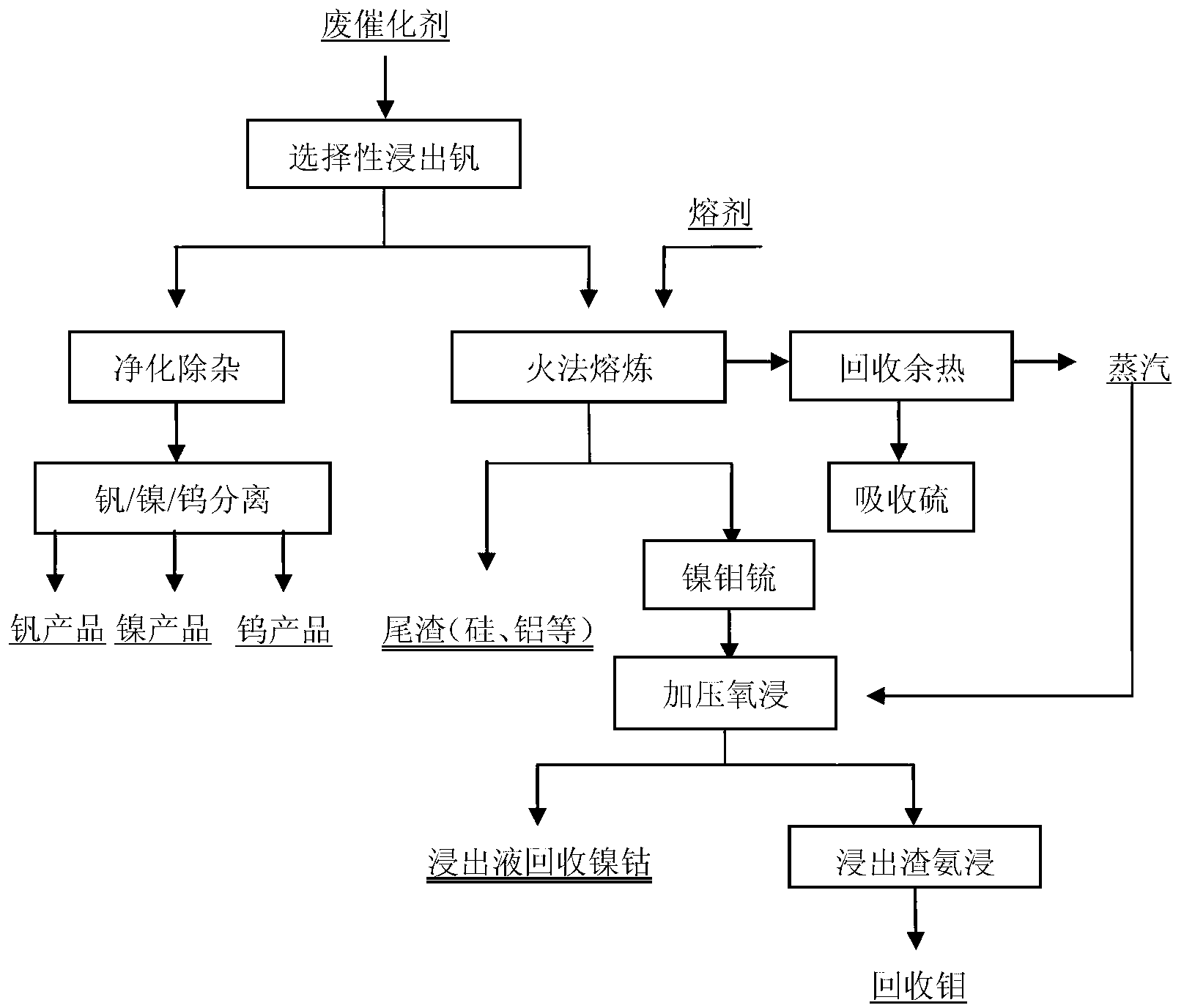

Comprehensive recovery method for multi-metal from dead catalyst

A waste catalyst and multi-metal technology, which is applied in the field of catalyst secondary resource recovery, can solve the problems of discarded renewable resources, difficulty in recycling, low resource recovery rate, etc., and achieve the effects of energy saving, process and cost saving, and wide adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Take 1000g of high-nickel catalyst from a petrochemical plant, pre-impregnate with sulfuric acid with a liquid-solid ratio of 5:1 and 100g / L in a stirring mill, and add concentrated sulfuric acid to the pre-soaked slag for aging. The slag-acid mass ratio is 4:1. The temperature is 106°C, and the aging time is 48h. The mature slag is leached with pre-soaking solution, the leaching temperature is 80°C, and the leaching time is 4h. After prepreg and aging water leaching, the leaching rate of vanadium was 88.0%, and the leaching rate of aluminum was 9.3%. The obtained leaching slag was mixed with silica and reduced iron powder, and smelted at 1350°C for 2 hours to obtain matte phase and slag phase. The matte ratios of nickel, cobalt, and molybdenum were 90%, 89%, and 82%, respectively. The matte phase is obtained by conventional metallurgical methods to obtain nickel, cobalt, and molybdenum products.

Embodiment 2

[0044] Take 1000g of high-cobalt waste catalyst from a petrochemical enterprise. The vanadium content in the catalyst is very low and has no recycling value. Therefore, it is directly smelted by fire method. According to the specific composition of the catalyst, 280g of silicon dioxide and 420g of reduced iron powder are mixed in. Melting at 1350°C for 2 hours, the matte phase and slag phase were obtained, and the matte-incorporated ratios of nickel, cobalt, and molybdenum were 94%, 95%, and 79%, respectively. The matte phase is obtained by conventional metallurgical methods to obtain nickel, cobalt, and molybdenum products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com