Ground wire junction method for spiral two-stage pre-finish welding set

A fine welding and ground wire technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., to achieve the effect of increasing the first pass rate, improving the production capacity of the line, and ensuring the welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

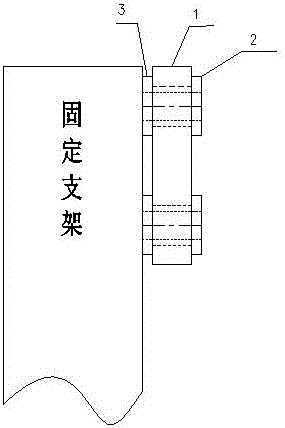

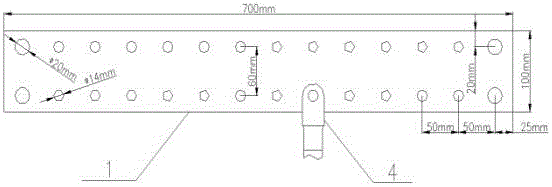

[0011] Embodiment 1: see figure 1 , figure 2 , a method of converging the ground wires of the spiral pre-finishing welding and finishing welding unit. 1) Find the appropriate position for the prepared bus bar 1. For the selection of the position, we choose the shortest straight-line distance from the conductive brush wiring bar and the space The location is enough for the bracket to be installed in the open space, and the bracket is fixed on site; 2) Install the prepared bus bar 1 on the bracket and insulate it well. The connection between the bus bar and the fixed bracket needs to be processed with insulating materials as above figure 1 As shown, the insulation between the bracket and the bus bar must be well insulated. If the insulation is not done well, the whole renovation project will fail); 3) Put the ground wire cable end connected to the welding machine at the lower end of the bus bar and press the connector. Then measure the length of the prepared cable and press th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com