Pipe limiting point forming clamp

A technology of limit points and pipe fittings, which is applied in the direction of manufacturing tools, auxiliary devices, auxiliary welding equipment, etc., can solve the problems such as the inability to guarantee the consistency of the insertion depth of pipe fittings, the inability to guarantee the welding strength, and the uneven gap between the insertion interfaces. Good performance, good product appearance, and the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

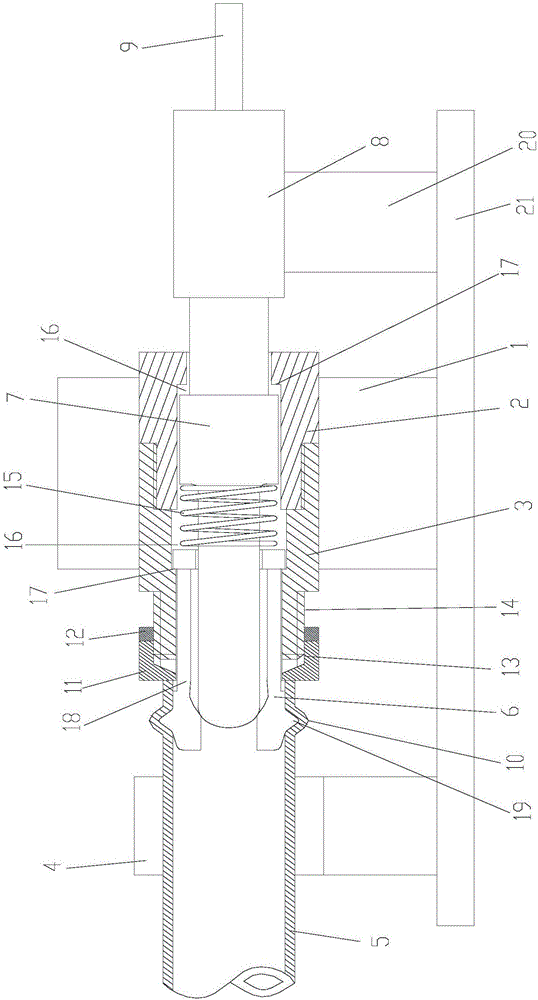

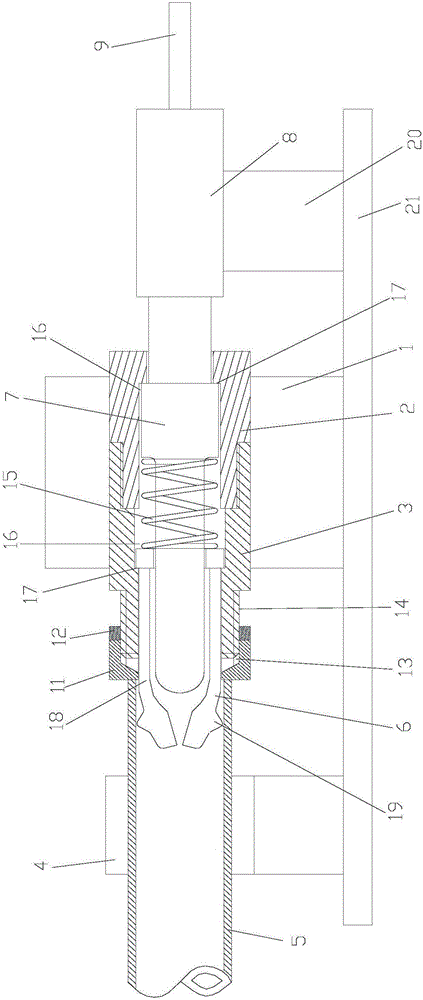

[0016] Attached below Figure 1-3 An embodiment of the present invention is described.

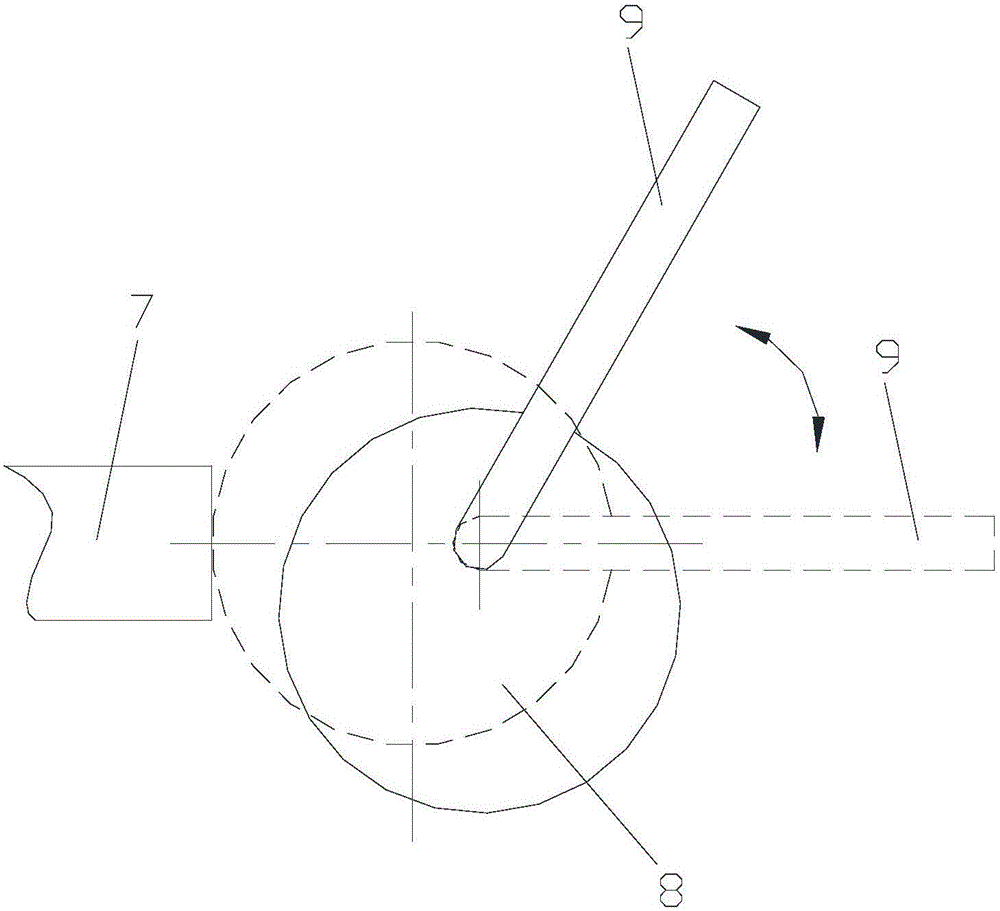

[0017] The pipe limit point forming fixture has a mounting seat 1, and the mounting seat 1 is provided with a fixed part 2 and a connecting part 3 connected to each other. The depth adjustment part is arranged at the left end of the connecting part 3 and is fixedly connected with the connecting part 3. The forming device The spring head 6 at the left end and the mandrel 7 at the right end of the forming device are arranged inside the fixing part 2 and the connecting part 3, respectively pass through and protrude from the depth adjustment part and the fixing part 2, and then place outside it. The part of the depth adjustment part is inserted into the pipe hole at the right end of the pipe part 5, which is located on the left side of the depth adjustment part and against the left end surface of the depth adjustment part. The wheel 8 is in contact with the mandrel 7, the handle 9 is fixedly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com