Dual-output-shaft hitting device for puncture wire clip

A technology of dual output shafts and puncture wire clips, which is applied in the field of electric power splicing and fire, can solve the problems of being unable to tighten the impact wrench and the bolt at the same time, difficulties and other problems, and achieve the effect of light weight, fast strike and good fire connection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

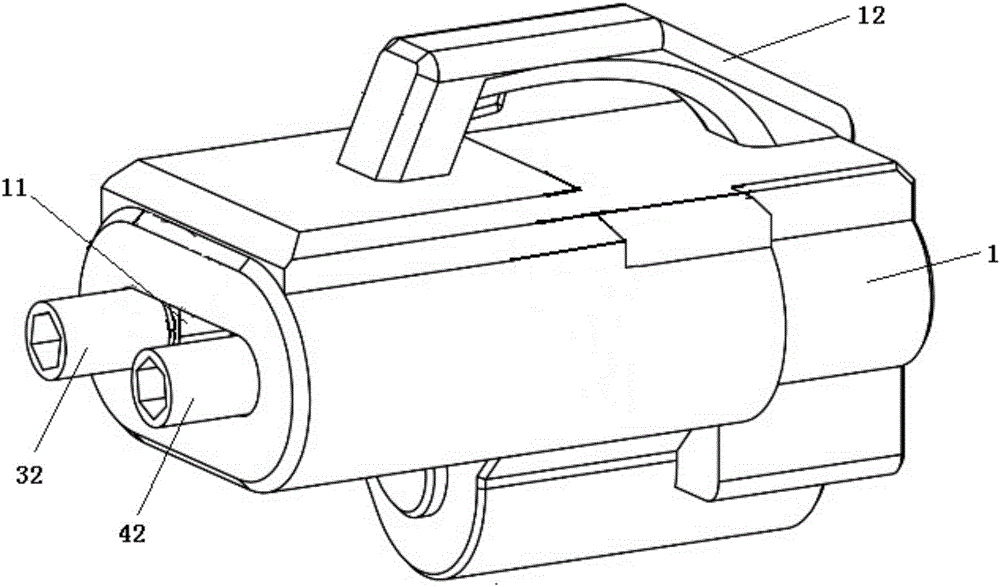

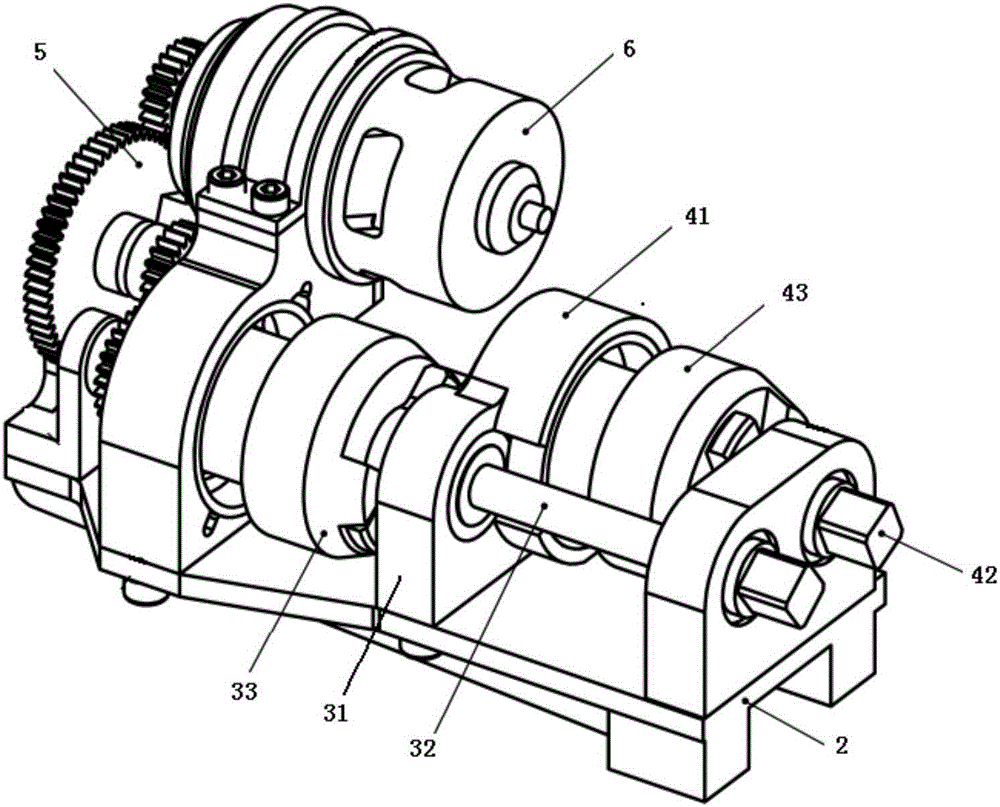

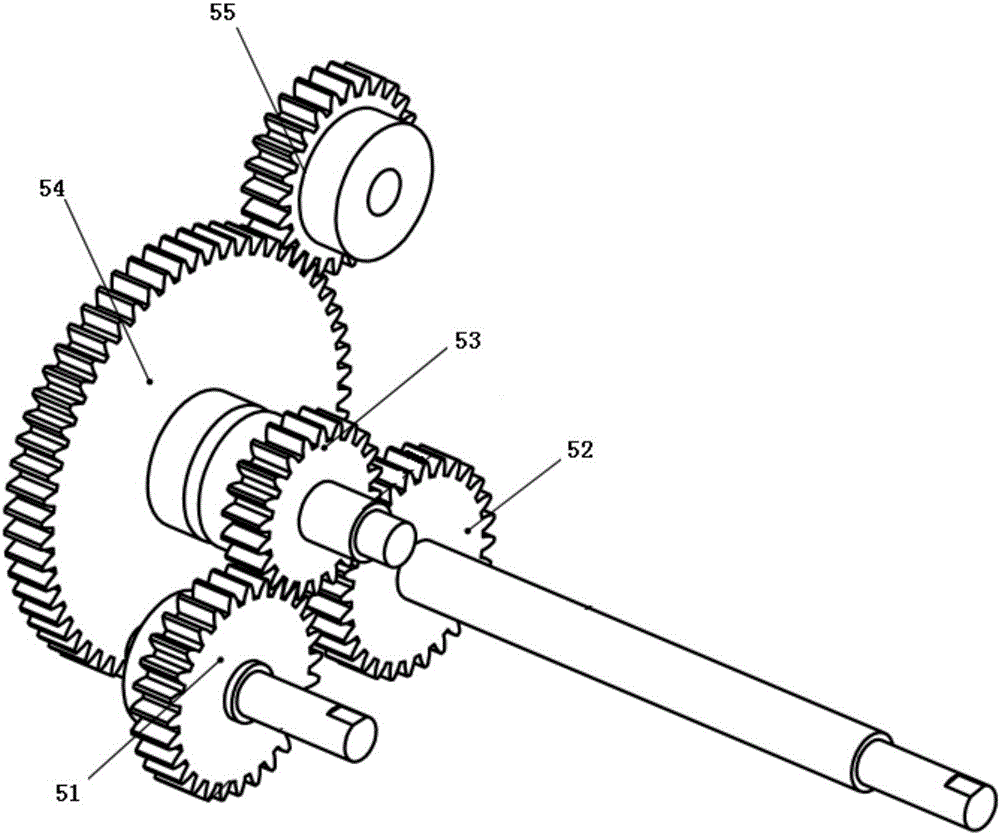

[0028] The invention provides a dual-output shaft striking device for piercing wire clips, which has the following functions: Figure 1-3 The structure shown, includes:

[0029] Shell 1: the shell 1 is provided with a window 11 and a handle 12;

[0030] Installation base 2: The installation base 2 is provided with double striking devices in parallel, which are respectively left striking device 3 and right striking device 4, wherein the left striking device 3 includes a left bearing seat 31, which is located on the left bearing seat The left output striking shaft 32 on the 31, the left striking block assembly 33 sleeved on the left output striking shaft 32; the right striking device 4 includes a right bearing seat 41, and the right output striking shaft set on the right bearing seat 42, and the right striking block assembly 43 sleeved on the right output striking shaft 42; the striking output ends of the left and right output striking shafts 32, 42 protrude out of the window 1...

Embodiment 2

[0035] This embodiment provides a dual-output-shaft striking device for a piercing wire clip with adjustable center distance, including:

[0036] Shell 1: the shell 1 is provided with a window 11 and a handle 12, and the edge of the window 11 is provided with a scale 13;

[0037] Installation base 2: The installation base 2 is provided with double striking devices in parallel, which are respectively left striking device 3 and right striking device 4, wherein the left striking device 3 includes a left bearing seat 31, which is located on the left bearing seat The left output striking shaft 32 on the 31, the left striking block assembly 33 sleeved on the left output striking shaft 32; the right striking device 4 includes a right bearing seat 41, and the right output striking shaft set on the right bearing seat 42, and the right striking block assembly 43 sleeved on the right output striking shaft 42; the striking output ends of the left and right output striking shafts 32, 42 ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com