Permanent magnet motor driven flaking mill

A permanent magnet motor and flaking technology, applied in the field of mechanical processing equipment and flaking machines, can solve the problems of inconvenient operation and production, manual manual adjustment, large floor space, etc., to achieve simple operation, reduce the weight of the whole machine, The effect of saving floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

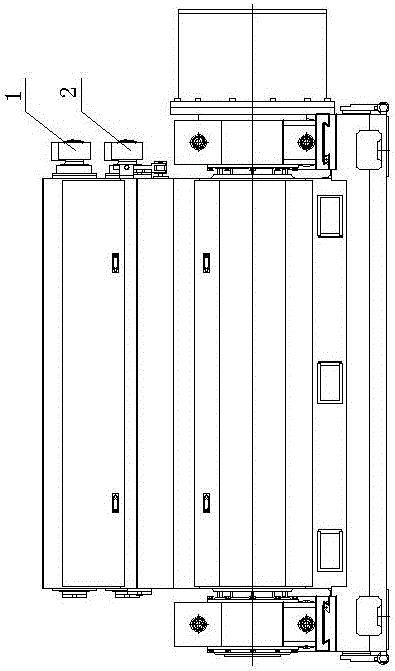

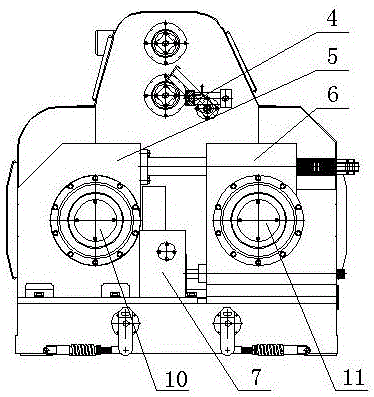

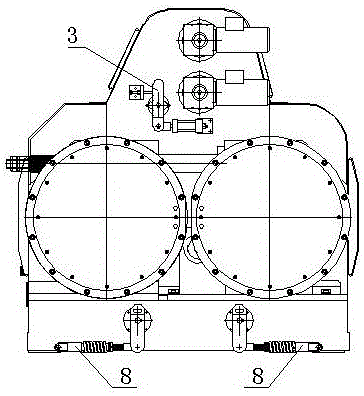

[0017] The structure of the permanent magnet motor-driven flaking machine of the present invention is as follows: Figure 1-4 As shown, the two ends of the movable roller 11 are installed on both sides of the frame through the movable bearing seat 6, and the two ends of the fixed roller 10 are installed on the two sides of the frame through the fixed bearing seat 5. The movable roller 11 and the fixed roller 10 One end is connected with a permanent magnet motor 9, and the fixed roller 10 and the movable roller 11 are directly driven by the permanent magnet motor 9. Between the fixed bearing seat 5 and the movable bearing seat 6, a roll distance adjusting device 7 is arranged. A homogenizing device 1 and a feeding device 2 are installed on the upper part of the housing, a material door device 3 is installed on one side of the housing, a magnetic separation device 4 is installed on the feeding roller side, and a scraper device 8 is installed under the roller.

[0018] Between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com