Paper cup manufacturing technique

A production process and technology of paper cups, applied in paper, papermaking, paper coating, etc., can solve the problems of poor anti-scalding effect, and achieve the effect of saving procedures, better anti-scalding effect, and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

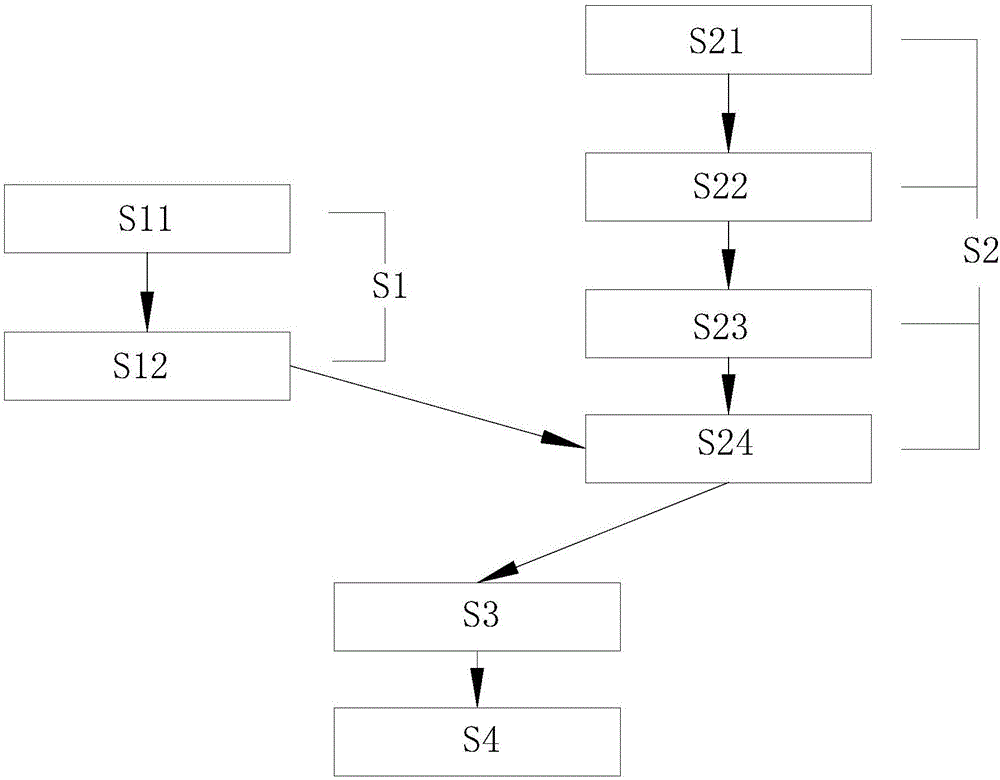

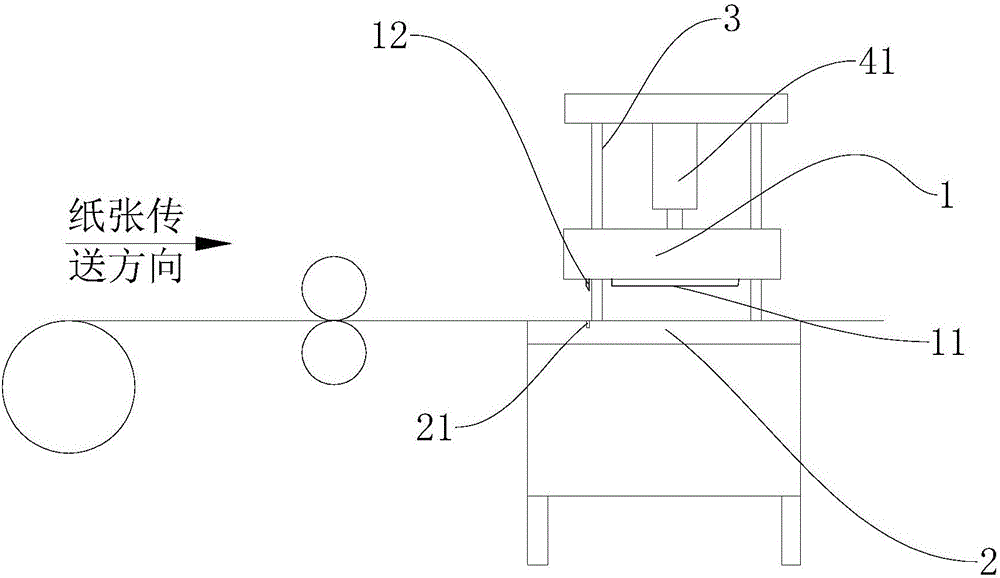

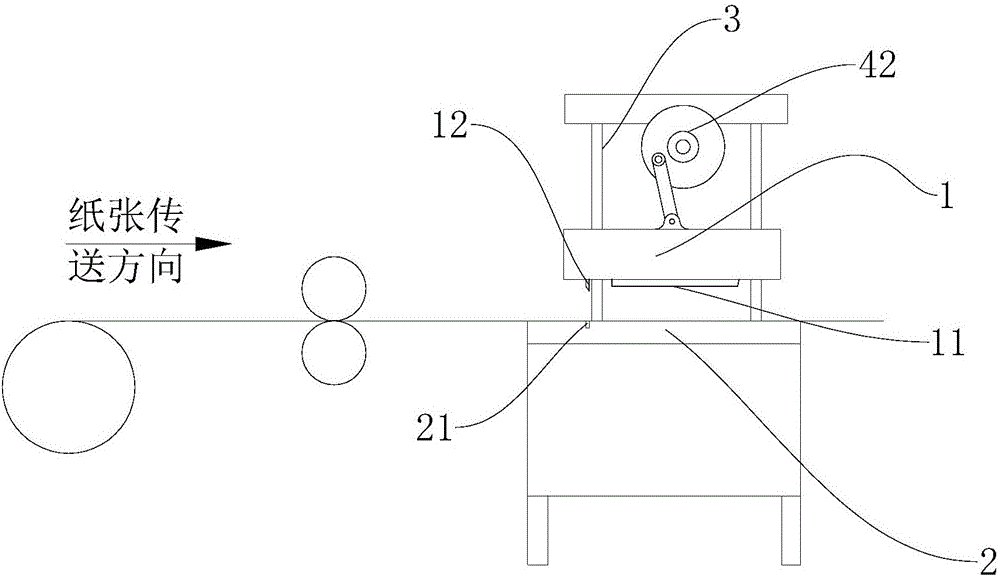

[0044] Such as Figure 1 to Figure 3 Shown is an embodiment of the paper cup production process of the present invention, comprising the following steps:

[0045] S1: Process the inner cup wall and compound with the cup bottom at the same time to form the cup body.

[0046] Wherein, the S1 processing procedure includes the following steps:

[0047] S11: Use base paper rolls for coating and die-cutting; cut a part of the bottom paper roll as the bottom roll of the cup; cut the other part into a fan shape as the inner cup wall;

[0048] The coating in this step adopts single-sided coating or double-sided coating. The inner wall of the cup body is coated with a film on one side, so that the inner wall of the cup can have the function of preventing moisture. The double-sided coating can protect both sides of the paper of the cup body, so that the cup has a better moisture-proof effect. In addition, in the process of holding water, the time of being wet by water increases.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com